Anodizing yog txheej txheem siv los tsim cov yeeb yaj kiab aluminium oxide rau ntawm cov khoom siv txhuas lossis txhuas alloy.Nws koom nrog muab cov khoom siv txhuas lossis txhuas hlau ua cov anode hauv cov tshuaj electrolyte thiab siv cov hluav taws xob tam sim no los tsim cov aluminium oxide zaj duab xis.Anodizing txhim kho corrosion kuj, hnav tsis kam, thiab cov khoom zoo nkauj ntawm aluminium profiles.Thaum lub sij hawm anodizing txheej txheem ntawm txhuas profiles, ntau yam tsis xws luag yuav tshwm sim.Cia peb nkag siab qhov ua rau pom qhov tsis xws luag.Cov khoom siv corrosion, da dej paug, nag lossis daus ntawm alloy thib ob theem, lossis cov teebmeem galvanic tuaj yeem ua rau pom qhov tsis xws luag.Lawv tau piav raws li hauv qab no:

1.Acid lossis alkali etching

Ua ntej anodizing, cov khoom siv txhuas yuav raug corroded los ntawm cov kua qaub los yog alkaline kua, los yog cuam tshuam los ntawm cov kua qaub los yog alkaline fumes, ua rau thaj chaw dawb ntawm qhov chaw.Yog tias qhov corrosion hnyav heev, qhov loj pitting tuaj yeem tsim.Nws yog ib qho nyuaj rau kev txiav txim siab nrog lub qhov muag liab qab seb qhov corrosion yog tshwm sim los ntawm cov kua qaub los yog alkali, tab sis nws tuaj yeem yooj yim paub qhov txawv los ntawm kev soj ntsuam qhov hla ntawm qhov chaw corroded nyob rau hauv lub tshuab ntsuas.Yog hais tias lub hauv qab ntawm lub qhov yog puag ncig thiab tsis muaj intergranular corrosion, nws yog tshwm sim los ntawm alkali etching.Yog tias hauv qab yog qhov tsis sib xws thiab nrog kev sib txuam ntawm kev sib tsoo, nrog cov qhov tob tob, nws yog tshwm sim los ntawm acid etching.Kev khaws cia tsis raug thiab tuav hauv lub Hoobkas kuj tuaj yeem ua rau hom corrosion.Acid fumes los ntawm chemical polishing agents los yog lwm yam acidic fumes, nrog rau chlorinated organic degreasers, yog qhov chaw ntawm acid etching.Feem ntau alkali etching yog tshwm sim los ntawm kev tawg thiab txaws ntawm mortar, cement tshauv, thiab alkaline ntxuav kua.Thaum qhov ua rau txiav txim siab, ntxiv dag zog rau kev tswj hwm ntawm ntau yam txheej txheem hauv lub Hoobkas tuaj yeem daws qhov teeb meem.

2. Atmospheric corrosion

Aluminium profiles raug huab cua ntub tuaj yeem tsim cov pob dawb, uas feem ntau ua kom ntev ntev raws cov kab pwm.Atmospheric corrosion feem ntau tsis hnyav li kua qaub lossis alkali etching thiab tuaj yeem raug tshem tawm los ntawm kev siv tshuab lossis alkaline ntxuav.Atmospheric corrosion feem ntau tsis nyob hauv zos thiab nyhav tshwm sim ntawm qee qhov chaw, xws li qhov chaw qis dua qhov dej vapor yooj yim condenses lossis rau saum npoo.Thaum atmospheric corrosion hnyav dua, ntu ntu ntawm pitting me ntsis tshwm zoo li inverted nceb.Nyob rau hauv rooj plaub no, alkaline ntxuav tsis tuaj yeem tshem tawm cov pob pitting thiab tej zaum yuav loj tuaj.Yog tias atmospheric corrosion raug txiav txim siab, qhov chaw cia khoom hauv lub Hoobkas yuav tsum tau kuaj xyuas.Cov ntaub ntawv txhuas yuav tsum tsis txhob muab khaws cia rau hauv qhov chaw uas muaj qhov kub thiab txias heev los tiv thaiv dej vapor condensation.Qhov chaw cia yuav tsum qhuav, thiab qhov kub thiab txias yuav tsum sib xws li qhov ua tau.

3.Paper corrosion (dej me ntsis)

Thaum daim ntawv lossis duab los qhia muab tso rau ntawm cov ntaub ntawv txhuas lossis siv rau ntim, nws tiv thaiv kev puas tsuaj.Txawm li cas los xij, yog tias daim ntawv dhau los ua ntub dej, qhov chaw corrosion tshwm rau ntawm qhov chaw ntawm txhuas.Thaum siv cov corrugated cardboard, cov kab tsis tu ncua ntawm cov kab xeb tshwm sim ntawm cov ntsiab lus ntawm kev sib cuag nrog lub rooj tsav xwm corrugated.Txawm hais tias qhov tsis xws luag tej zaum yuav pom ncaj qha rau ntawm qhov chaw txhuas, lawv feem ntau qhia tau meej dua tom qab alkaline ntxuav thiab anodizing.Cov pob no feem ntau sib sib zog nqus thiab nyuaj rau tshem tawm los ntawm kev siv tshuab lossis alkaline ntxuav.Daim ntawv (board) corrosion yog tshwm sim los ntawm acid ions, feem ntau yog SO42- thiab Cl-, uas muaj nyob rau hauv daim ntawv.Yog li ntawd, siv daim ntawv (board) yam tsis muaj chlorides thiab sulfates thiab tsis txhob nkag mus rau hauv dej yog txoj kev zoo los tiv thaiv daim ntawv (board) corrosion.

4.Tshuaj dej corrosion (tseem hu ua snowflake corrosion)

Tom qab alkaline ntxuav, tshuaj polishing, los yog sulfuric acid pickling, yog hais tias cov dej yaug muaj impurities, nws yuav ua rau lub hnub qub-zoo li tus los yog radiating me ntsis ntawm qhov chaw.Qhov tob corrosion yog ntiav.Hom kev xeb no tshwm sim thaum cov dej ntxuav tau hnyav heev los yog thaum cov dej ntws ntws tawm tsawg.Nws zoo li snowflake-puab crystals nyob rau hauv tsos, li no lub npe "snowflake corrosion."Qhov ua rau yog cov tshuaj tiv thaiv ntawm impurities ntawm zinc hauv txhuas thiab SO42- thiab Cl- hauv cov dej ntxuav.Yog tias cov rwb thaiv tsev ntawm lub tank tsis zoo, cov teebmeem galvanic tuaj yeem ua rau qhov tsis xws luag.Raws li cov ntaub ntawv txawv teb chaws, thaum cov ntsiab lus ntawm Zn nyob rau hauv aluminium alloy yog ntau dua 0.015%, Cl- hauv cov dej ntxuav yog siab tshaj 15 ppm, hom corrosion no yuav tshwm sim.Siv nitric acid rau pickling lossis ntxiv 0.1% HNO3 rau cov dej ntxuav tuaj yeem tshem tawm nws.

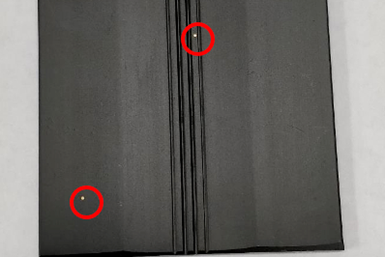

5.Chloride corrosion

Lub xub ntiag ntawm me me ntawm chloride nyob rau hauv sulfuric acid anodizing da dej kuj tuaj yeem ua rau pitting corrosion.Cov yam ntxwv zoo li yog qhov sib sib zog nqus dub lub hnub qub zoo li lub pits, uas muaj ntau lub ntsej muag ntawm cov npoo thiab cov ces kaum ntawm lub workpiece los yog lwm qhov chaw uas muaj ntau dua tam sim no.Cov chaw pitting tsis muaj cov yeeb yaj kiab anodized, thiab cov tuab ntawm cov yeeb yaj kiab hauv qhov seem "ib txwm" yog qis dua li qhov xav tau.Cov ntsiab lus ntsev siab hauv cov kais dej yog qhov tseem ceeb ntawm Cl- pa phem hauv chav da dej.

6. Galvanic corrosion

Nyob rau hauv lub energized tank (anodizing los yog electrolytic xim), galvanic teebmeem ntawm workpiece thiab lub tank (steel tank), los yog cov teebmeem ntawm stray tam sim no nyob rau hauv lub tank tsis-energized (rinsing los yog sealing), yuav ua rau aggravate pitting corrosion.

Kho los ntawm May Jiang los ntawm MAT Aluminium

Post lub sij hawm: Dec-15-2023