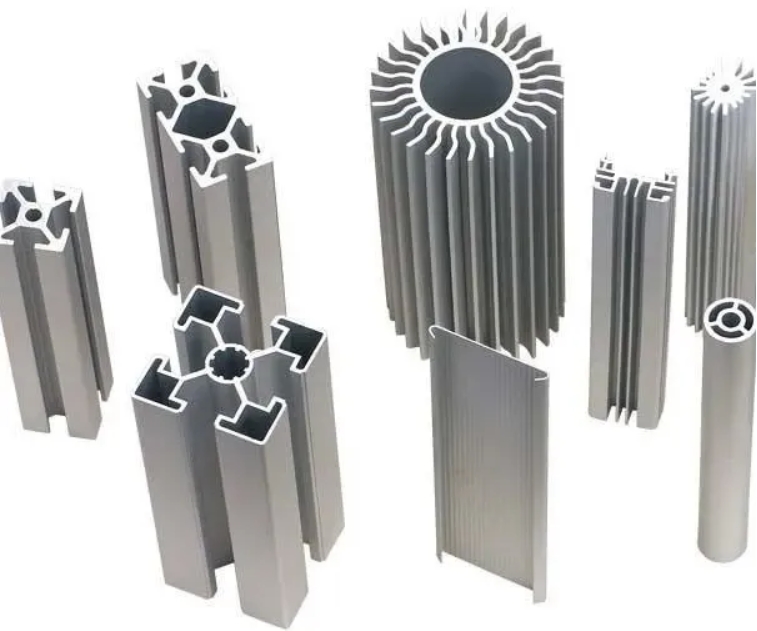

Aluminium yog ib yam khoom uas feem ntau tau teev tseg rau extrusion thiab cov duab profiles vim tias nws muaj cov khoom siv kho tshuab uas ua rau nws zoo tagnrho rau kev tsim thiab shaping hlau los ntawm billet seem. Lub siab ductility ntawm txhuas txhais tau hais tias cov hlau tuaj yeem yooj yim tsim rau hauv ntau qhov sib txawv yam tsis siv ntau lub zog hauv kev ua haujlwm lossis kev tsim cov txheej txheem, thiab txhuas kuj feem ntau muaj qhov melting point ntawm ib nrab ntawm cov hlau zoo tib yam. Ob qhov tseeb no txhais tau hais tias cov txheej txheem extrusion aluminium profile yog lub zog qis, uas txo cov cuab yeej thiab cov nqi tsim khoom. Thaum kawg, aluminium kuj muaj lub zog siab rau qhov hnyav piv, ua rau nws yog qhov kev xaiv zoo tshaj plaws rau kev lag luam.

Raws li ib tug byproduct ntawm cov txheej txheem extrusion, nplua, yuav luag tsis pom kab tuaj yeem tshwm sim nyob rau saum npoo ntawm qhov profile. Qhov no yog qhov tshwm sim ntawm kev tsim cov cuab yeej pabcuam thaum lub sijhawm extrusion, thiab kev kho deg ntxiv tuaj yeem raug teev tseg kom tshem tawm cov kab no. Txhawm rau txhim kho qhov ua tiav ntawm qhov profile, ntau qhov kev kho mob thib ob xws li lub ntsej muag milling tuaj yeem ua tau tom qab lub ntsiab extrusion txheej txheem. Cov kev ua haujlwm machining tuaj yeem raug teev los txhim kho qhov geometry ntawm qhov chaw txhawm rau txhim kho qhov profile los ntawm kev txo qhov roughness tag nrho ntawm cov extruded profile. Cov kev kho mob no feem ntau tau teev tseg rau hauv daim ntawv thov uas yuav tsum tau muab tso rau ntawm qhov chaw los yog qhov chaw mating yuav tsum nruj nruj tswj.

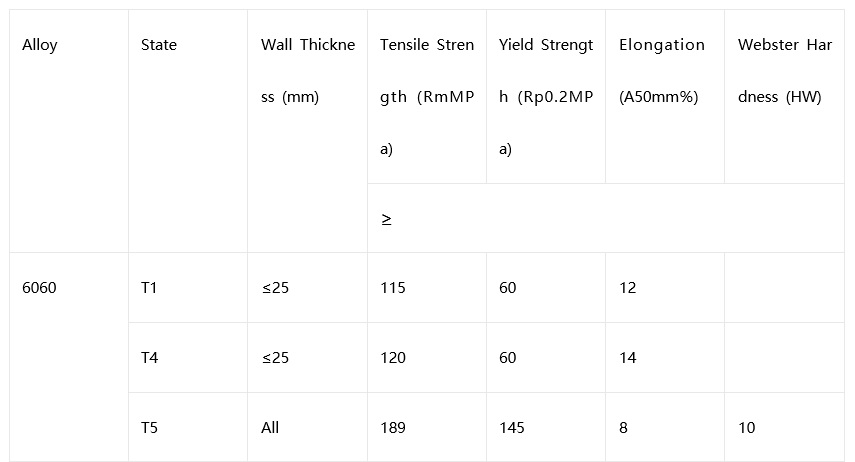

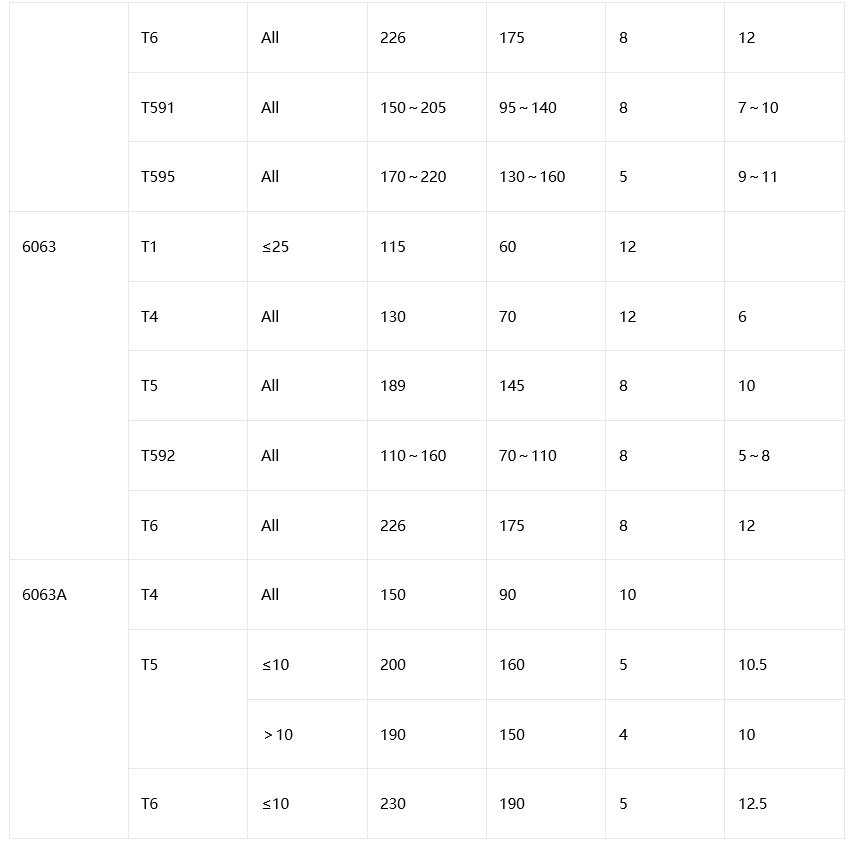

Peb feem ntau pom cov khoom kem cim nrog 6063-T5 / T6 los yog 6061-T4, thiab lwm yam. Lub 6063 los yog 6061 nyob rau hauv lub cim no yog lub hom ntawm txhuas profile, thiab T4 / T5 / T6 yog lub xeev ntawm txhuas profile. Yog li dab tsi yog qhov txawv ntawm lawv?

Piv txwv li: Cias muab, 6061 txhuas profile muaj lub zog zoo dua thiab txiav kev ua tau zoo, nrog rau siab toughness, zoo weldability thiab corrosion kuj; 6063 aluminium profile muaj cov yas zoo dua, uas tuaj yeem ua rau cov khoom ua tau zoo dua, thiab tib lub sijhawm muaj zog tensile ntau dua thiab cov khoom muaj zog, qhia tau hais tias zoo dua tawg toughness, thiab muaj lub zog siab, hnav tsis kam, corrosion kuj thiab kub tsis kam.

T4 xeev:

kev kho mob + natural aging, uas yog, aluminium profile yog txias tom qab extruded los ntawm extruder, tab sis tsis muaj hnub nyoog nyob rau hauv lub aging furnace. Aluminium profile uas tsis tau muaj hnub nyoog muaj ib tug kuj tsis tshua muaj hardness thiab zoo deformability, uas yog haum rau tom qab khoov thiab lwm yam deformation ua.

T5 xeev:

kev kho mob + tsis tiav kev laus kev laus, uas yog, tom qab cua txias quenching tom qab extrusion, thiab tom qab ntawd xa mus rau lub qhov cub laus kom sov li ntawm 200 degrees rau 2-3 teev. Aluminium nyob rau hauv lub xeev no muaj ib tug kuj siab hardness thiab ib tug tej yam degree ntawm deformability. Nws yog feem ntau siv hauv cov ntaub thaiv phab ntsa.

T6 xeev:

kev kho mob + ua tiav kev laus laus, uas yog, tom qab dej txias quenching tom qab extrusion, cov khoom qub tom qab quenching yog siab tshaj T5 kub, thiab lub sij hawm rwb thaiv tsev kuj ntev dua, thiaj li ua tiav lub xeev hardness siab dua, uas yog haum rau tej lub sij hawm uas kuj yuav tsum tau rau cov khoom hardness.

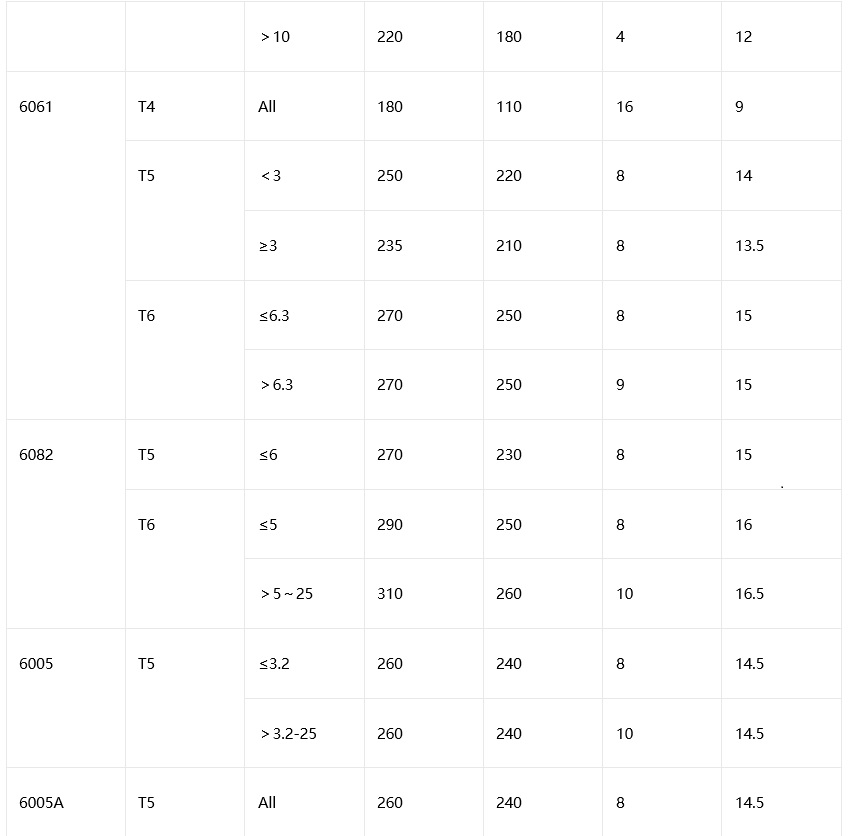

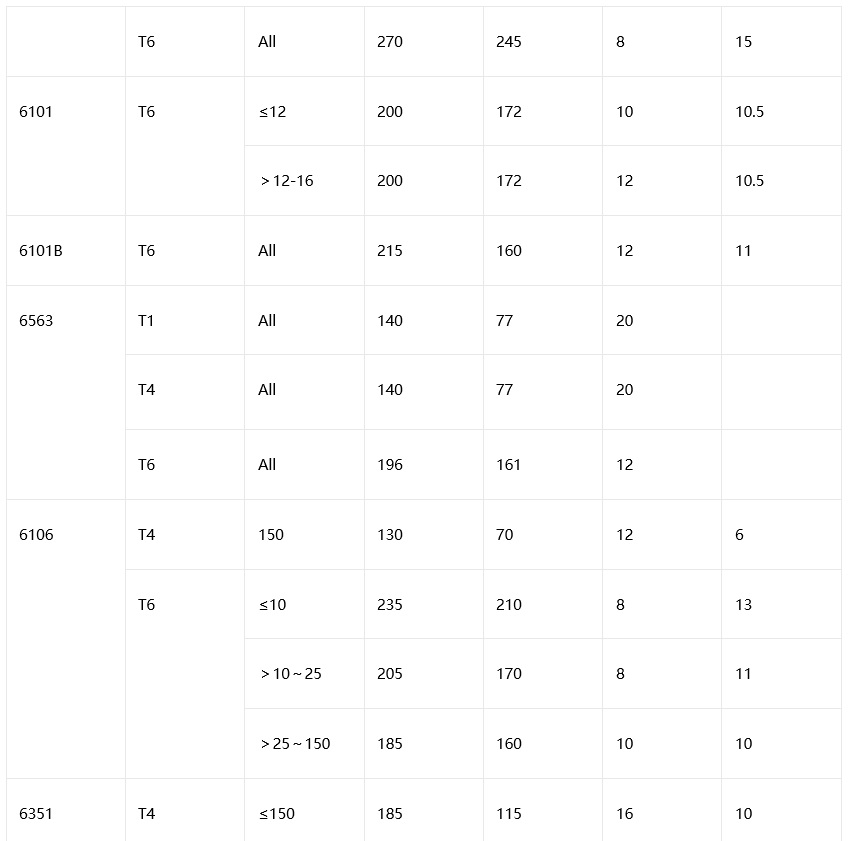

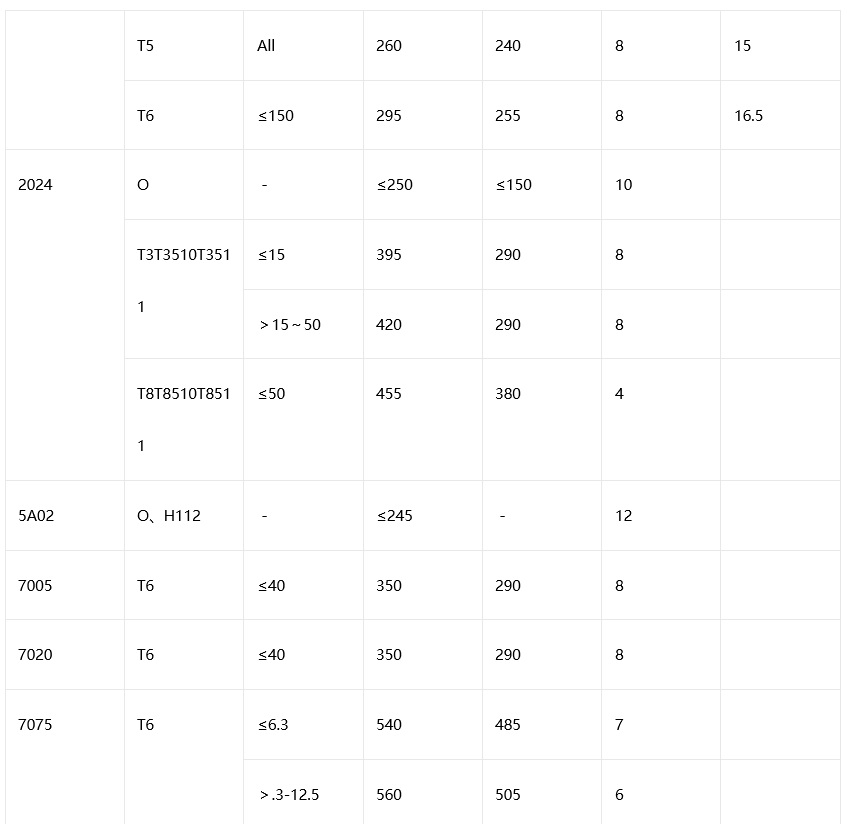

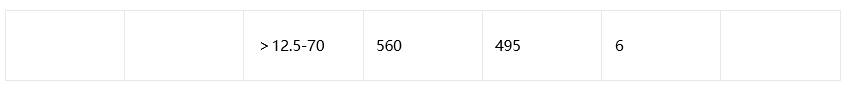

Cov khoom siv hluav taws xob ntawm aluminium profiles ntawm cov ntaub ntawv sib txawv thiab cov xeev sib txawv tau piav qhia hauv qab no:

Yield zog:

Nws yog qhov kev txwv ntawm cov khoom siv hlau thaum lawv tawm los, uas yog, kev ntxhov siab uas tiv thaiv micro yas deformation. Rau cov khoom siv hlau tsis muaj qhov pom tseeb, qhov kev ntxhov siab uas ua rau 0.2% residual deformation yog teev raws li nws qhov kev txwv tsis pub dhau, uas yog hu ua conditional yield limit lossis yield zog. Sab nraud quab yuam ntau dua qhov kev txwv no yuav ua rau cov khoom ua tsis tiav thiab tsis tuaj yeem rov qab los.

Tensile zog:

Thaum aluminium yields mus rau ib qho twg, nws lub peev xwm los tiv thaiv deformation nce ntxiv vim qhov rov kho ntawm cov nplej sab hauv. Txawm hais tias qhov deformation loj hlob sai nyob rau lub sijhawm no, nws tsuas tuaj yeem nce ntxiv nrog kev nce siab kom txog thaum qhov kev ntxhov siab nce mus txog qhov siab tshaj plaws. Tom qab ntawd, lub peev xwm ntawm qhov profile los tiv thaiv deformation yog txo qis, thiab cov yas loj deformation tshwm sim ntawm qhov tsis muaj zog tshaj plaws. Qhov hla ntawm cov qauv ntawm no shrinks sai heev, thiab caj dab tshwm sim kom txog thaum nws tawg.

Webster hardness:

Lub hauv paus ntsiab lus ntawm Webster hardness yog siv lub quenched siab koob ntawm ib tug tej yam duab los nias rau hauv lub nto ntawm tus qauv nyob rau hauv lub quab yuam ntawm ib tug qauv caij nplooj ntoos hlav, thiab txhais ib tug tob ntawm 0.01MM raws li ib tug Webster hardness unit. Lub hardness ntawm cov khoom yog inversely proportional rau qhov tob ntawm nkag. Qhov tob qhov nkag mus, siab dua qhov hardness, thiab vice versa.

Yas deformation:

Qhov no yog hom deformation uas tsis tuaj yeem rov qab los ntawm tus kheej. Thaum cov khoom siv hluav taws xob thiab cov khoom siv tau thauj khoom dhau ntawm qhov elastic deformation ntau yam, qhov deformation mus tas li yuav tshwm sim, uas yog, tom qab tshem tawm cov khoom, qhov tsis tuaj yeem deformation lossis seem deformation yuav tshwm sim, uas yog yas deformation.

Post lub sij hawm: Oct-09-2024