6063 aluminium alloy belongs rau qis-alloyed Al-Mg-Si series tshav kub kho aluminium alloy. Nws muaj kev ua tau zoo extrusion molding kev ua tau zoo, zoo corrosion kuj thiab cov khoom siv txhua yam. Nws kuj yog siv dav hauv kev lag luam tsheb vim nws yooj yim oxidation xim. Nrog rau kev nrawm ntawm cov qauv ntawm lub tsheb sib tw, daim ntawv thov ntawm 6063 aluminium alloy extrusion cov ntaub ntawv hauv kev lag luam tsheb kuj tau nce ntxiv.

Lub microstructure thiab cov khoom ntawm cov ntaub ntawv extruded raug cuam tshuam los ntawm kev sib xyaw ua ke ntawm extrusion ceev, extrusion kub thiab extrusion piv. Ntawm lawv, qhov sib piv extrusion feem ntau yog txiav txim siab los ntawm extrusion siab, ntau lawm efficiency thiab ntau lawm khoom. Thaum lub extrusion piv yog me me, lub alloy deformation yog me me thiab lub microstructure refinement tsis pom tseeb; nce qhov sib piv extrusion tuaj yeem ua kom zoo dua cov nplej, rhuav tshem cov ntxhib theem thib ob, tau txais ib qho microstructure, thiab txhim kho cov khoom siv ntawm cov hlau.

6061 thiab 6063 aluminium alloys undergo dynamic recrystallization thaum lub sij hawm extrusion txheej txheem. Thaum lub extrusion kub tsis tu ncua, raws li qhov sib piv extrusion nce, cov qoob loo txo qis, lub zog ntawm cov theem yog finely dispersed, thiab lub zog tensile thiab elongation ntawm cov alloy nce raws li; Txawm li cas los xij, raws li qhov sib piv extrusion nce, lub zog extrusion xav tau rau cov txheej txheem extrusion kuj nce, ua rau cov nyhuv thermal ntau dua, ua rau qhov kub thiab txias ntawm cov alloy nce, thiab kev ua haujlwm ntawm cov khoom yuav txo. Qhov kev sim no kawm txog cov nyhuv ntawm extrusion piv, tshwj xeeb tshaj yog loj extrusion piv, ntawm microstructure thiab mechanical zog ntawm 6063 aluminium alloy.

1 Cov ntaub ntawv sim thiab cov txheej txheem

Cov khoom siv sim yog 6063 aluminium alloy, thiab cov tshuaj lom neeg muaj pes tsawg leeg tau pom nyob rau hauv Table 1. Qhov loj me ntawm lub ingot yog Φ55 hli × 165 hli, thiab nws tau ua tiav rau hauv ib qho extrusion billet nrog qhov loj ntawm Φ50 hli × 150 hli tom qab homogenization kho ntawm 560 ℃ rau 6 h. Lub billet yog rhuab mus rau 470 ℃ thiab ua kom sov. Lub preheating kub ntawm lub extrusion chim yog 420 ℃, thiab lub preheating ntawm pwm yog 450 ℃. Thaum lub extrusion ceev (extrusion pas nrig txav ceev) V = 5 mm / s tseem tsis hloov, 5 pawg ntawm cov sib txawv extrusion piv kev ntsuam xyuas yog nqa tawm, thiab cov extrusion ratios R yog 17 (xav mus rau lub qhov tuag txoj kab uas hla D = 12 mm), 25 (D = 10 mm), 39 (D = 8 mm), 69 (D = 16 mm), 69 (D = 16 mm), 69 (D = 16 mm),

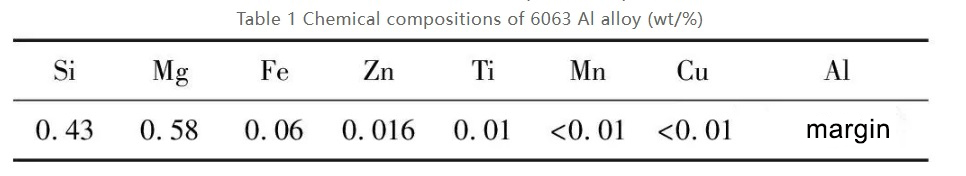

Table 1 Tshuaj muaj pes tsawg leeg ntawm 6063 Al alloy (wt /%)

Tom qab cov ntawv xuab zeb sib tsoo thiab tshuab polishing, cov qauv metallographic tau etched nrog HF reagent nrog ib feem ntawm 40% rau li 25 s, thiab cov qauv metallographic ntawm cov qauv tau soj ntsuam ntawm LEICA-5000 optical microscope. Ib qho kev ntsuas kev ntxhib los mos nrog qhov loj ntawm 10 mm × 10 mm raug txiav los ntawm qhov nruab nrab ntawm qhov ntev ntawm tus pas nrig extruded, thiab kev sib tsoo tshuab thiab etching tau ua kom tshem tawm cov txheej txheem kev ntxhov siab. Cov duab ncej tsis tiav ntawm peb lub dav hlau siv lead ua {111}, {200}, thiab {220} ntawm cov qauv raug ntsuas los ntawm X′Pert Pro MRD X-ray diffraction analyzer ntawm PANalytical Company, thiab cov ntaub ntawv zoo nkauj tau ua tiav thiab tshuaj xyuas los ntawm X′Pert Data View thiab X′Pert Texture software.

Lub tensile specimen ntawm cov cam khwb cia hlau yog muab los ntawm qhov chaw ntawm lub ingot, thiab lub tensile specimen raug txiav raws li extrusion kev taw qhia tom qab extrusion. Qhov ntsuas thaj tsam loj yog Φ4 mm × 28 mm. Kev ntsuas tensile tau ua tiav siv SANS CMT5105 universal khoom kuaj tshuab nrog tensile tus nqi ntawm 2 mm / min. Qhov nruab nrab tus nqi ntawm peb tus qauv qauv raug xam raws li cov ntaub ntawv kho tshuab. Lub pob txha morphology ntawm cov qauv tensile tau pom siv lub tshuab ntsuas hluav taws xob qis (Quanta 2000, FEI, USA).

2 Cov txiaj ntsig thiab kev sib tham

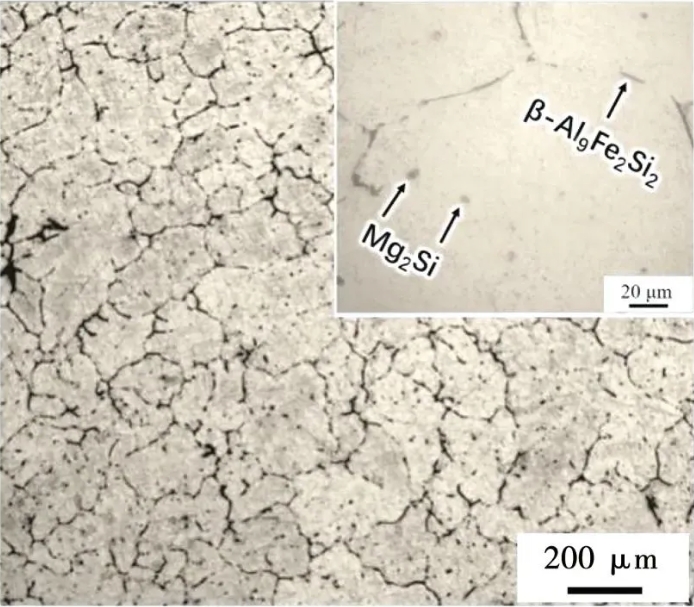

Daim duab 1 qhia cov metallographic microstructure ntawm as-cam khwb cia 6063 aluminium alloy ua ntej thiab tom qab kev kho mob homogenization. Raws li pom nyob rau hauv daim duab 1a, α-Al nplej nyob rau hauv as-cast microstructure sib txawv nyob rau hauv loj, ib tug loj tus naj npawb ntawm reticular β-Al9Fe2Si2 theem sib sau ua ke nyob rau hauv lub grain ciam teb, thiab ib tug loj tus naj npawb ntawm granular Mg2Si theem muaj nyob rau hauv cov nplej. Tom qab lub ingot yog homogenized ntawm 560 ℃ rau 6 h, lub non-equilibrium eutectic theem ntawm cov alloy dendrites maj yaj, cov ntsiab lus alloy yaj mus rau hauv lub matrix, lub microstructure yog uniform, thiab qhov nruab nrab grain loj yog hais txog 125 μm (Daim duab 1b).

Ua ntej homogenization

Tom qab uniformizing kho ntawm 600 ° C rau 6 teev

Fig.1 Metallographic qauv ntawm 6063 aluminium alloy ua ntej thiab tom qab kev kho mob homogenization

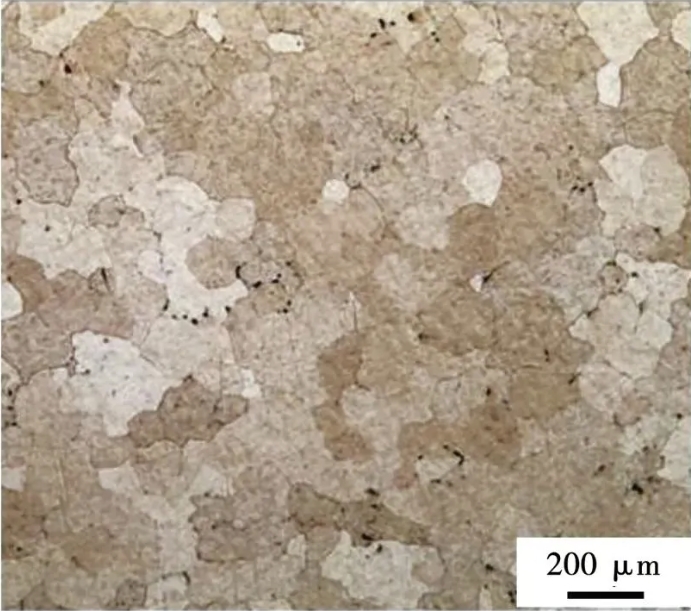

Daim duab 2 qhia txog cov tsos ntawm 6063 txhuas alloy tuav nrog sib txawv extrusion piv. Raws li pom nyob rau hauv daim duab 2, qhov zoo ntawm 6063 aluminium alloy bars extruded nrog txawv extrusion ratios yog zoo, tshwj xeeb tshaj yog thaum lub extrusion ratio yog nce mus rau 156 (xws li bar extrusion qhov hluav taws xob ceev ntawm 48 m / min), tseem tsis muaj extrusion defects xws li cov kab nrib pleb thiab tev rau ntawm qhov chaw ntawm lub bar extrusion 6 yog qhov zoo ntawm kev ua tau zoo. kev kub ceev thiab loj extrusion piv.

Fig.2 Cov tsos ntawm 6063 aluminium alloy rods nrog txawv extrusion ratios

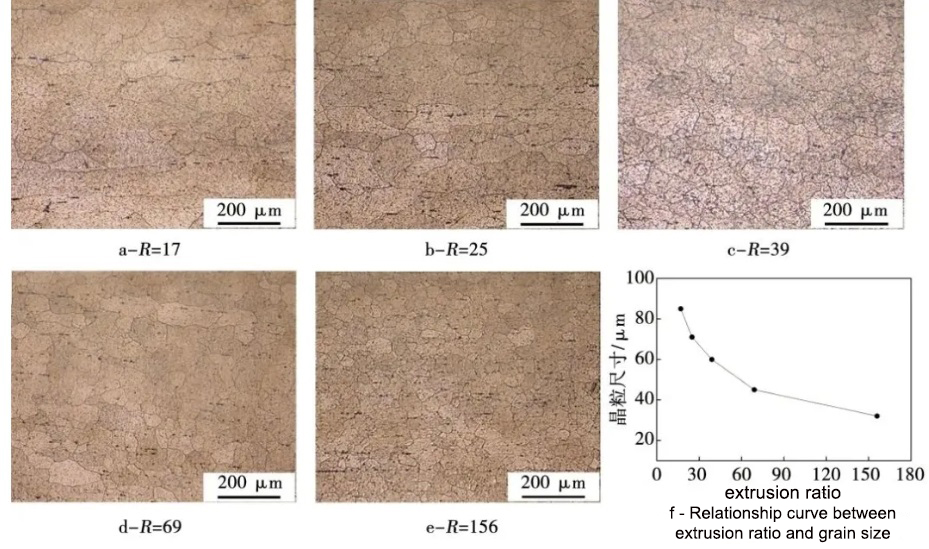

Daim duab 3 qhia tau hais tias cov metallographic microstructure ntawm lub longitudinal seem ntawm 6063 aluminium alloy bar nrog txawv extrusion ratios. Cov qauv nplej ntawm lub bar nrog sib txawv extrusion ratios qhia txawv qib ntawm elongation los yog refinement. Thaum lub extrusion ratio yog 17, cov thawj nplej yog elongated raws lub extrusion kev taw qhia, nrog rau cov tsim ntawm ib tug me me ntawm recrystallized nplej, tab sis cov nplej tseem kuj coarse, nrog ib tug nruab nrab grain loj ntawm txog 85 μm (Daim duab 3a); thaum lub extrusion piv yog 25, cov nplej tau rub ntau dua, cov nplej recrystallized nce, thiab qhov nruab nrab ntawm cov nplej txo mus txog 71 μm (Daim duab 3b); thaum lub extrusion ratio yog 39, tshwj tsis yog rau ib tug me me ntawm deformed nplej, lub microstructure yog yeej muaj li ntawm equiaxed recrystallized nplej ntawm uneven loj, nrog ib tug nruab nrab grain loj ntawm txog 60 μm (Daim duab 3c); Thaum cov extrusion ratio yog 69, cov txheej txheem dynamic recrystallization yog qhov pib ua tiav, cov nplej ntxhib qub tau hloov pauv tag nrho rau hauv cov txheej txheem recrystallized, thiab qhov nruab nrab cov nplej loj yog refined txog 41 μm (Daim duab 3d); Thaum lub extrusion ratio yog 156, nrog rau tag nrho cov kev kawm ntawm dynamic recrystallization txheej txheem, lub microstructure yog ntau uniform, thiab cov grain loj yog zoo heev refined mus txog 32 μm (Daim duab 3e). Nrog rau qhov nce ntawm extrusion piv, cov txheej txheem dynamic recrystallization ua tiav ntau dua, cov hlau nplaum microstructure ua ntau dua, thiab cov nplej loj yog qhov ua kom zoo dua qub (Daim duab 3f).

Fig.3 Metallographic qauv thiab grain loj ntawm longitudinal seem ntawm 6063 txhuas alloy rods nrog txawv extrusion ratios

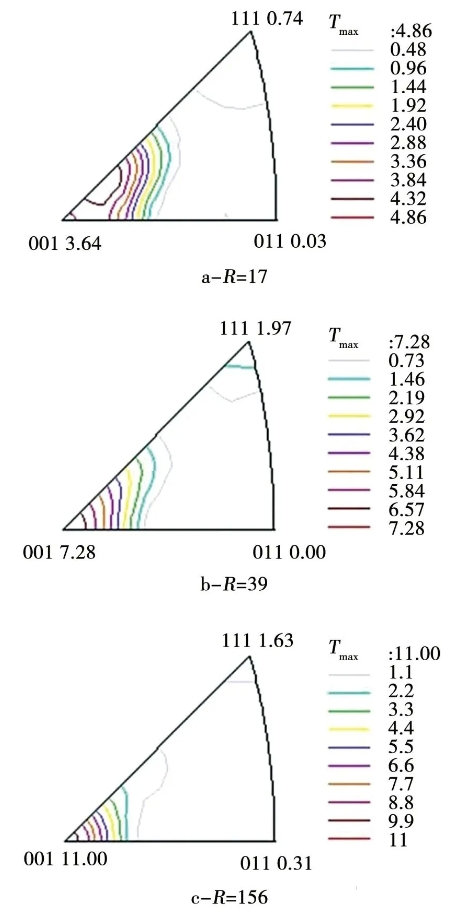

Daim duab 4 qhia txog tus ncej ncej ntawm 6063 txhuas alloy tuav nrog sib txawv extrusion ratios raws li extrusion kev taw qhia. Nws tuaj yeem pom tau tias cov microstructures ntawm alloy tuav nrog sib txawv extrusion ratios tag nrho tsim pom tseeb nyiam orientation. Thaum qhov sib piv extrusion yog 17, qhov tsis muaj zog <115>+<100> kev ntxhib los mos yog tsim (Daim duab 4a); thaum qhov sib piv extrusion yog 39, cov khoom siv kev ntxhib los mos yog qhov muaj zog <100> kev ntxhib los mos thiab qhov me me ntawm qhov tsis muaj zog <115> kev ntxhib los mos (Daim duab 4b); Thaum qhov sib piv extrusion yog 156, qhov kev ntxhib los mos yog qhov <100> kev ntxhib los mos nrog lub zog loj, thaum lub <115> kev ntxhib los mos ploj (Daim duab 4c). Cov kev tshawb fawb tau pom tias lub ntsej muag-centered cubic hlau feem ntau tsim <111> thiab <100> hlau textures thaum extrusion thiab kos duab. Thaum qhov kev ntxhib los mos yog tsim, chav tsev kub txhua yam khoom ntawm cov hlau qhia pom tseeb anisotropy. Qhov kev ntxhib los mos lub zog nce nrog qhov nce ntawm qhov sib piv ntawm extrusion, qhia tias tus naj npawb ntawm cov nplej nyob rau hauv ib qho kev coj ua siv lead ua piv rau cov kev taw qhia extrusion nyob rau hauv cov hlau maj mam nce, thiab longitudinal tensile lub zog ntawm cov alloy nce. Cov txheej txheem ntxiv dag zog ntawm 6063 aluminium alloy kub extrusion cov ntaub ntawv suav nrog nplua nplej ntxiv dag zog, dislocation ntxiv dag zog, kev ntxhib los mos ntxiv dag zog, thiab lwm yam. Nyob rau hauv qhov ntau ntawm cov txheej txheem tsis siv nyob rau hauv qhov kev sim no, nce qhov sib piv extrusion muaj kev txhawb zog ntawm cov txheej txheem saum toj no.

Fig.4 Rov qab ncej daim duab ntawm 6063 txhuas alloy rods nrog sib txawv extrusion ratios raws li extrusion kev taw qhia

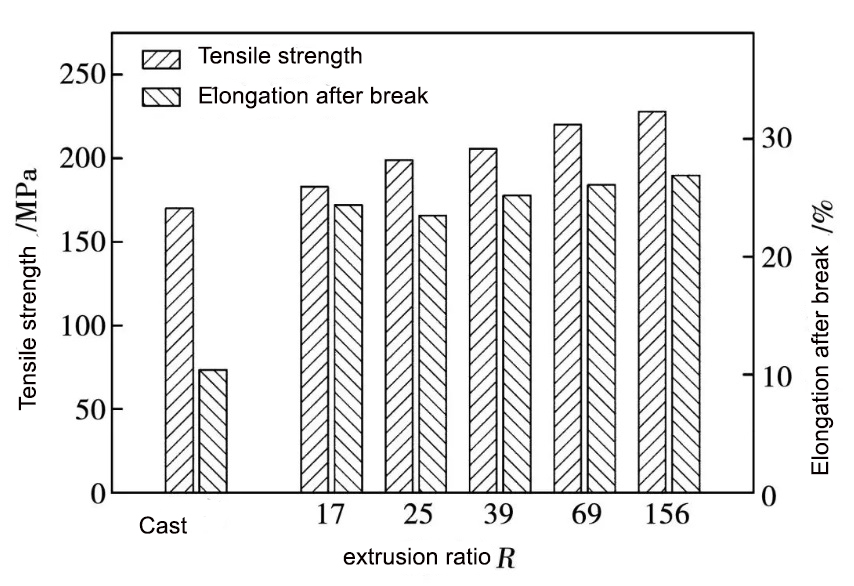

Daim duab 5 yog ib tug histogram ntawm tensile zog ntawm 6063 txhuas alloy tom qab deformation ntawm txawv extrusion ratios. Lub zog tensile ntawm cov cam khwb cia hlau yog 170 MPa thiab elongation yog 10.4%. Lub zog tensile thiab elongation ntawm cov hlau tom qab extrusion yog qhov zoo dua, thiab lub zog tensile thiab elongation maj mam nce nrog qhov nce ntawm extrusion piv. Thaum lub extrusion piv yog 156, lub zog tensile thiab elongation ntawm cov alloy ncav cuag tus nqi siab tshaj plaws, uas yog 228 MPa thiab 26.9%, feem, uas yog hais txog 34% siab tshaj lub tensile lub zog ntawm cov cam khwb cia hlau thiab txog 158% siab tshaj qhov elongation. Lub zog tensile ntawm 6063 aluminium alloy tau los ntawm qhov sib piv loj extrusion yog ze rau lub zog tensile tus nqi (240 MPa) tau los ntawm 4-pass vaj huam sib luag channel angular extrusion (ECAP), uas yog ntau dua li tus nqi tensile zog (171.1 MPa) tau los ntawm 1-pass ECAP extrusion ntawm 6063 txhuas alloy. Nws tuaj yeem pom tias qhov sib piv loj extrusion tuaj yeem txhim kho cov khoom siv kho tshuab ntawm cov hlau rau qee yam.

Kev txhim kho ntawm cov khoom siv ntawm cov hlau alloy los ntawm extrusion piv feem ntau yog los ntawm cov nplej refinement ntxiv dag zog rau. Raws li qhov sib piv extrusion nce, cov nplej yog refined thiab qhov dislocation ceev nce. Ntau thaj tsam ntawm ib cheeb tsam tuaj yeem cuam tshuam kev txav ntawm kev txav mus los, ua ke nrog kev sib koom ua ke thiab kev cuam tshuam ntawm dislocations, yog li txhim kho lub zog ntawm cov hlau. Lub finer cov nplej, ntau tortuous lub grain ciam teb, thiab cov yas deformation yuav dispersed nyob rau hauv ntau nplej, uas yog tsis conducive rau tsim ntawm cov kab nrib pleb, cia nyob ib leeg rau propagation ntawm cov kab nrib pleb. Ntau lub zog tuaj yeem nqus tau thaum lub sijhawm tawg, yog li txhim kho cov yas ntawm cov hlau.

Fig.5 Tensile zog ntawm 6063 aluminium alloy tom qab casting thiab extrusion

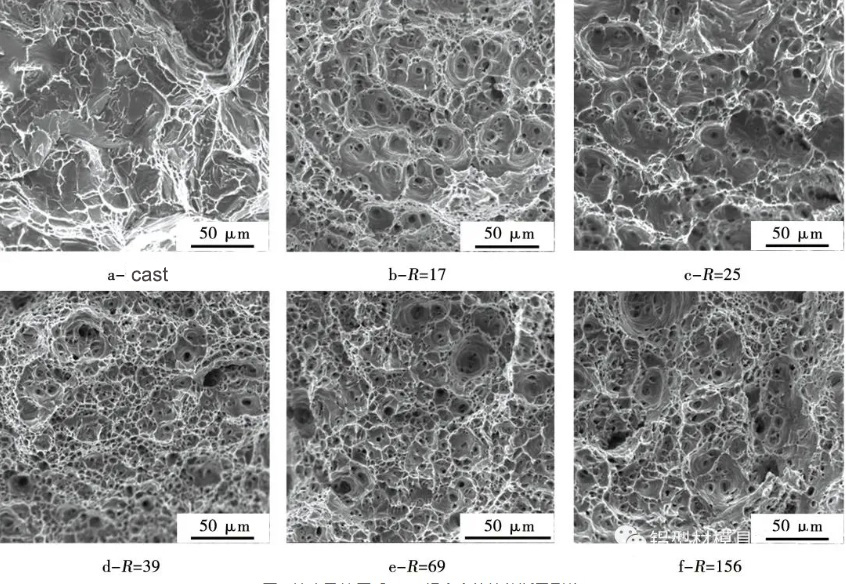

Lub tensile fracture morphology ntawm lub alloy tom qab deformation nrog txawv extrusion ratios yog pom nyob rau hauv daim duab 6. Tsis muaj dimples tau pom nyob rau hauv lub pob txha morphology ntawm cov qauv as-cam khwb cia (Daim duab 6a), thiab cov pob txha yog tsuas yog tsim los ntawm cov cheeb tsam tiaj tus thiab tearing npoo, qhia tau hais tias lub tensile brittle fracture mechanism ntawm lub ntsiab. Cov pob txha morphology ntawm cov hlau tom qab extrusion tau hloov pauv loj heev, thiab cov pob txha tawg yog tsim los ntawm ntau cov equiaxed dimples, qhia tias cov txheej txheem tawg ntawm cov hlau tom qab extrusion tau hloov los ntawm cov pob txha tawg mus rau cov pob txha tawg. Thaum qhov sib piv extrusion me me, cov dimples ntiav thiab qhov dimple loj loj, thiab kev faib tawm tsis sib npaug; Raws li qhov sib piv extrusion nce, tus naj npawb ntawm dimples nce, qhov dimple qhov me me thiab qhov kev faib tawm yog qhov sib xws (Daim duab 6b ~ f), uas txhais tau hais tias cov hlau alloy muaj cov yas zoo dua, uas zoo ib yam nrog cov khoom siv kho tshuab kuaj tau saum toj no.

3 Kev xaus

Hauv qhov kev sim no, qhov cuam tshuam ntawm qhov sib txawv extrusion ratios ntawm microstructure thiab cov khoom ntawm 6063 aluminium alloy tau soj ntsuam nyob rau hauv cov xwm txheej hais tias qhov loj ntawm billet, ingot cua kub kub thiab extrusion ceev tseem tsis hloov. Cov lus xaus yog raws li nram no:

1) Dynamic recrystallization tshwm sim hauv 6063 aluminium alloy thaum kub extrusion. Nrog rau qhov nce ntawm extrusion piv, cov nplej tau ua kom zoo dua qub, thiab cov nplej elongated raws cov kev taw qhia extrusion yog hloov mus rau hauv equiaxed recrystallized nplej, thiab lub zog ntawm <100> hlau zoo nkauj yog tsis tu ncua.

2) Vim tias cov txiaj ntsig zoo ntawm cov nplej ntxiv dag zog, cov khoom siv kho tshuab ntawm cov hlau tau txhim kho nrog qhov nce ntawm extrusion piv. Tsis pub dhau qhov ntsuas qhov ntsuas, thaum qhov sib piv extrusion yog 156, lub zog tensile thiab elongation ntawm cov hlau ncav cuag qhov siab tshaj plaws ntawm 228 MPa thiab 26.9%, feem.

Fig.6 Tensile tawg morphologies ntawm 6063 txhuas alloy tom qab casting thiab extrusion

3) Cov pob txha tawg morphology ntawm cov qauv zoo li-cam khwb cia yog tsim los ntawm cov chaw tiaj tus thiab cov kua muag tawm. Tom qab extrusion, cov pob txha tawg yog tsim los ntawm ntau cov equiaxed dimples, thiab cov txheej txheem tawg yog hloov los ntawm cov pob txha tawg mus rau cov pob txha tawg.

Post lub sij hawm: Nov-30-2024