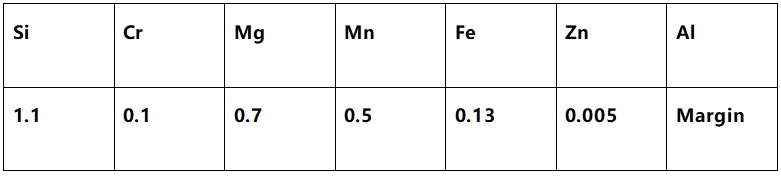

1. Alloy muaj pes tsawg leeg

2. Homogenization txheej txheem

390 ℃ x rwb thaiv tsev rau 1.0h + 575 ℃ x rwb thaiv tsev rau 8h, muaj zog cua txias rau 200 ℃ thiab tom qab ntawd dej txias.

3. Metallographic Structure

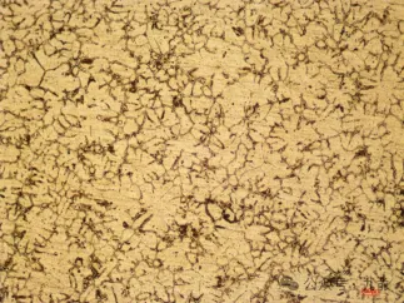

Daim duab 1 Metallographic qauv ntawm cov tub ntxhais ntawm 6082 alloy ingot, etched los ntawm Keller reagent, nrog zoo-tsim dendrites

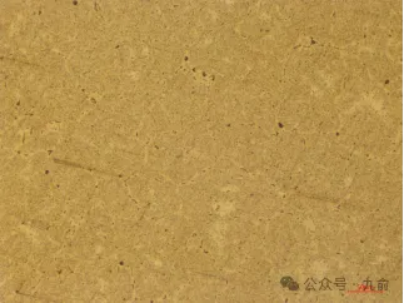

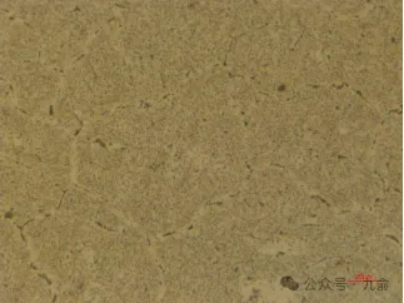

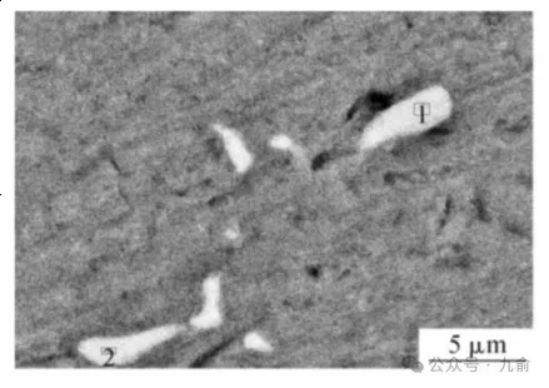

Daim duab 2 Metallographic qauv ntawm cov tub ntxhais ntawm 6082 alloy ingot, etched los ntawm Keller reagent, thiab cov qauv tom qab kev daws teeb meem

4. Cov nyhuv ntawm homogenization tshav kub kho ntawm cov qauv alloy

4.1 Raws li pom nyob rau hauv daim duab 1, lub alloy muaj zoo-tsim dendrites nyob rau hauv lub cam khwb cia lub xeev, thiab muaj ib tug loj tus naj npawb ntawm network uas tsis yog-equilibrium nag lossis daus theem nyob rau hauv lub grain ciam teb.

4.2 Txij li thaum cov ntsiab lus melting ntawm cov ntsiab lus sib txawv yog qhov sib txawv thaum lub alloy solidifies, qhov tshwm sim ntawm cov khoom sib txuas ua ke ua rau cov kua dej tsis sib xws hauv cov siv lead ua, uas tau tshwm sim tshwj xeeb hauv cov cim ntawm ntau lub network nag lossis daus theem ntawm thaj tsam lis.

4.3 Hauv microstructure tom qab kev kho mob homogenization (Daim duab 2), tus nqi ntawm precipitated theem ntawm cov qoob loo ciam teb tau txo qis heev, thiab cov qoob loo loj zuj zus tuaj. Qhov no yog vim hais tias lub diffusion ntawm atoms yog txhim kho nyob rau hauv high kub, cais cais tawm thiab non-equilibrium theem dissolution tshwm sim nyob rau hauv lub ingot, thiab lub network tebchaw nyob rau hauv lub grain ciam teb yog ib feem yaj.

4.4 Los ntawm SEM tsom xam, raws li qhia nyob rau hauv FIG3, qhov sib txawv ntawm cov theem precipitated raug xaiv rau EDS tsom xam, paub meej tias lub precipitated theem yog Al(MnFe)Si theem.

4.5 Thaum lub sij hawm alloy casting, ib tug loj npaum li cas ntawm Mn-muaj nag lossis daus theem yog tsim, thiab ib feem ntawm nws yog khaws cia nyob rau hauv lub supersaturated khoom tov. Tom qab kub-kub thiab ntev-ntev homogenization kev kho mob, Mn supersaturated nyob rau hauv lub matrix precipitates nyob rau hauv daim ntawv ntawm Mn-muaj compounds, uas yog manifested raws li ib tug loj tus naj npawb ntawm dispersed Mn-muaj compound decomposition particles precipitated nyob rau hauv lub siv lead ua (Daim duab 2).

4.6 Txij li cov theem precipitated muaj Mn keeb, nws muaj thermal stability zoo. Nrog rau kev siv zog ntawm atomic diffusion, Al (MnFe) Si theem hais maj mam qhia cov yam ntxwv spheroidization.

Fig.3 Al (MnFe) Si theem hauv 6082 alloy

5. Cov nyhuv ntawm kev daws kev laus zog ntawm cov khoom siv kho tshuab

Tom qab homogenization, lub network precipitated theem Ameslikas nyob rau hauv lub grain ciam teb ntawm 6082 alloy yog yaj, uas muaj peev xwm txhim kho cov zoo txhua yam khoom ntawm tus qauv. Nyob rau tib lub sij hawm, qhov ruaj khov tshav kub-resistant theem Al (MnFe) Si theem yog ntxiv spheroidized, uas yuav zoo dua pin dislocations. Qhov no qhia tau hais tias kev ua tau zoo ntawm cov khoom siv yuav raug txhim kho tom qab homogenization kev kho cua sov.

6. Cov lus xaus

6.1 Lub 6082 aluminium alloy ingot muaj qhov tsim tau zoo dendrites thiab ntau lub network tsis sib npaug ntawm cov nag lossis daus ntawm cov ciam teb.

6.2 Tom qab kev kho mob homogenization, kev soj ntsuam microscopic qhia tau hais tias tus nqi ntawm precipitated theem tau txo qis heev, thiab cov nplej loj nce synchronously. Kev tshem tawm kev sib cais thiab qhov tsis sib npaug ntawm qhov sib npaug tshwm sim nyob rau hauv lub ingot, thiab lub network sib txuas ntawm cov ciam teb nplej tau ib nrab yaj.

6.3 Thaum casting 6082 alloy, Al (MnFe) Si nag lossis daus theem yog generated. Qhov no nag lossis daus theem muaj Mn keeb thiab muaj thermal stability zoo. Raws li cov txheej txheem homogenization pib, cov nag lossis daus theem hais maj mam qhia cov yam ntxwv spheroidization. Qhov no Mn-muaj cov khoom sib xyaw ua ke yog sib xyaw ua ke thiab precipitated hauv cov siv lead ua.

6.4 Tom qab homogenization kev kho mob, lub dissolution ntawm lub network precipitated theem qhia tias tag nrho cov kev ua tau zoo ntawm tag nrho cov ingot yog zoo dua tom qab homogenization tshav kub kho.

Post lub sij hawm: Jun-08-2025