Yog hais tias cov khoom ntawm extrusion tsis yog raws li qhov xav tau, kev saib xyuas feem ntau yog tsom rau qhov pib muaj pes tsawg leeg ntawm billet lossis extrusion / aging tej yam kev mob. Tsawg tus neeg nug seb homogenization nws tus kheej puas yog qhov teeb meem. Qhov tseeb, theem homogenization yog qhov tseem ceeb rau kev tsim cov khoom zoo extrusion. Ua tsis tau zoo tswj cov kauj ruam homogenization yuav ua rau:

● Ua kom nrawm nrawm

● Ntau yam tsis xws luag

● Streak textures tom qab anodizing

● qis extrusion ceev

● Cov khoom siv tsis zoo

Lub homogenization theem muaj ob lub hom phiaj tseem ceeb: refining hlau-muaj intermetallic tebchaw, thiab redistributing magnesium (Mg) thiab silicon (Si). Los ntawm kev tshuaj xyuas lub microstructure ntawm billet ua ntej thiab tom qab homogenization, ib tug tuaj yeem kwv yees seb lub billet yuav ua tau zoo thaum lub sij hawm extrusion.

Cov nyhuv ntawm Billet Homogenization ntawm Hardening

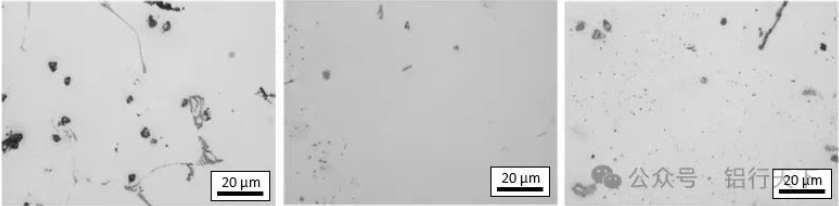

Hauv 6XXX extrusion, lub zog los ntawm Mg- thiab Si-nplua nuj theem tsim thaum laus. Lub peev xwm los tsim cov theem no yog nyob ntawm qhov muab cov ntsiab lus rau hauv cov tshuaj tov ua ntej kev laus pib. Rau Mg thiab Si kom nws thiaj li dhau los ua ib feem ntawm cov khoom siv, cov hlau yuav tsum tau quenched sai ntawm saum toj 530 ° C. Thaum kub saum toj no, Mg thiab Si ib txwm yaj rau hauv txhuas. Txawm li cas los xij, thaum lub sij hawm extrusion, cov hlau tsuas yog nyob saum qhov kub no rau lub sijhawm luv luv. Txhawm rau kom ntseeg tau tias tag nrho Mg thiab Si yaj, Mg thiab Si hais yuav tsum yog me me. Hmoov tsis zoo, thaum lub sij hawm casting, Mg thiab Si precipitate li loj Mg₂Si blocks (Fig. 1a).

Ib lub voj voog homogenization rau 6060 billets yog 560 ° C rau 2 teev. Thaum lub sij hawm tus txheej txheem no, txij li thaum lub billet nyob saum 530 ° C rau ib lub sij hawm ntev, Mg₂Si yaj. Thaum txias, nws rov ua dua hauv kev faib tawm ntau dua (Fig. 1c). Yog tias qhov kub ntawm homogenization tsis siab txaus, lossis lub sijhawm luv luv, qee qhov loj Mg₂Si yuav nyob twj ywm. Thaum qhov no tshwm sim, cov kev daws teeb meem tom qab extrusion muaj tsawg dua mg thiab si, ua rau nws tsis yooj yim sua kom tsim lub zog ua ntej ua ntej ua ntej ua ntej.

Fig. 1. Optical micrographs ntawm polished thiab 2% HF-etched 6060 billets: (a) as-cam khwb cia, (b) ib nrab homogenized, (c) tag nrho homogenized.

Lub luag haujlwm ntawm Homogenization ntawm Hlau-muaj Intermetallic

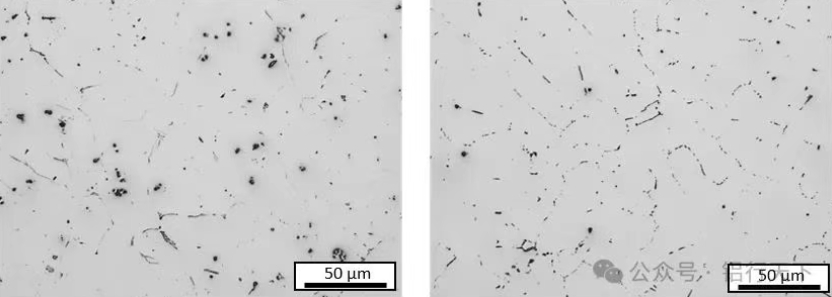

Hlau (Fe) muaj kev cuam tshuam ntau dua ntawm kev puas ntsoog toughness dua li ntawm lub zog. Hauv 6XXX alloys, Fe theem zoo li tsim β-theem (Al₅(FeMn)Si lossis Al₈.₉(FeMn)₂Si₂) thaum lub sijhawm casting. Cov theem no yog loj, angular, thiab cuam tshuam nrog extrusion (highlighted nyob rau hauv daim duab 2a). Thaum lub sij hawm homogenization, cov ntsiab lus hnyav (Fe, Mn, thiab lwm yam) diffuse, thiab loj angular theem ua me thiab rounder (Fig. 2b).

Los ntawm cov duab kho qhov muag ib leeg, nws yog ib qho nyuaj rau kev paub qhov txawv ntawm ntau theem, thiab nws yog qhov tsis yooj yim sua kom ntseeg tau tias muaj pes tsawg leeg. Ntawm Innoval, peb suav cov billet homogenization siv peb cov kev tshawb nrhiav sab hauv thiab kev faib tawm (FDC), uas muab % α tus nqi rau billets. Qhov no ua rau peb ntsuas qhov zoo ntawm homogenization.

Fig. 2. Optical micrographs ntawm billets (a) ua ntej thiab (b) tom qab homogenization.

Kev Tshawb Fawb Txog Kev Tshawb Fawb thiab Kev faib tawm (FDC) Txoj Kev

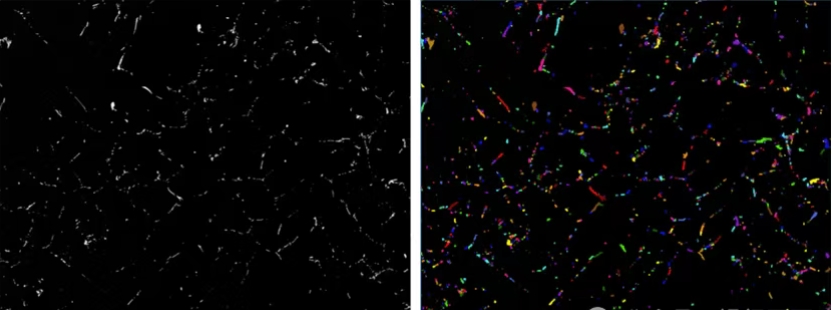

Daim duab 3a qhia tau hais tias tus qauv polished soj ntsuam los ntawm scanning electron microscopy (SEM). Cov txheej txheem greyscale thresholding yog siv los cais thiab txheeb xyuas cov intermetallic, uas tshwm dawb hauv daim duab 3b. Cov txheej txheem no tso cai rau kev txheeb xyuas thaj tsam txog li 1 mm², lub ntsiab lus ntau dua 1000 tus neeg tuaj yeem txheeb xyuas ib zaug.

Daim duab 3. (a) Backscattered electron duab ntawm homogenized 6060 billet, (b) txheeb xyuas tus kheej nta ntawm (a).

Particle Composition

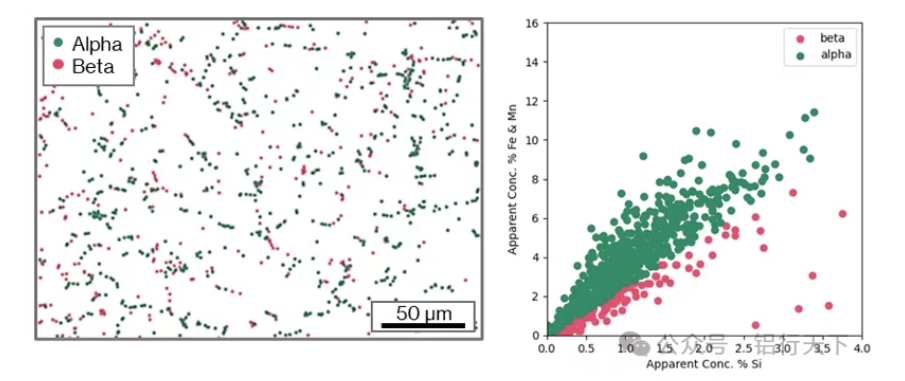

Lub Innoval system yog nruab nrog Oxford Instruments Xplore 30 lub zog-dispersive X-ray (EDX) ntes. Qhov no tso cai rau ceev ceev tsis siv neeg sau ntawm EDX spectra los ntawm txhua qhov taw qhia. Los ntawm cov spectra no, cov particle muaj pes tsawg leeg yuav raug txiav txim, thiab tus txheeb ze Fe: Si piv inferred.

Nyob ntawm Mn lossis Cr cov ntsiab lus ntawm cov hlau, lwm cov khoom hnyav kuj tuaj yeem suav nrog. Rau qee qhov 6XXX alloys (qee zaum nrog Mn tseem ceeb), (Fe + Mn): Si piv yog siv los siv. Cov piv txwv no tuaj yeem muab piv rau cov uas paub Fe-muaj intermetallics.

β-phase (Al₅(FeMn)Si or Al₈.₉(FeMn)₂Si₂): (Fe+Mn):Si ratio ≈ 2. α-phase (Al₁₂(FeMn)₃Si–Al₈.₃(FeMn) 4.₃Si ratio, nyob ntawm seb muaj pes tsawg leeg. Peb cov kev cai software tso cai rau peb los teeb tsa qhov pib thiab faib txhua qhov raws li α lossis β, tom qab ntawd qhia lawv txoj haujlwm hauv microstructure (Fig. 4). Qhov no muab kwv yees feem pua ntawm kev hloov pauv α hauv homogenized billet.

Fig. 4. (a) Daim ntawv qhia qhia txog α- thiab β-chaw ua haujlwm, (b) scatter plot of (Fe+Mn): Si ratios.

Dab tsi cov ntaub ntawv tuaj yeem qhia rau peb

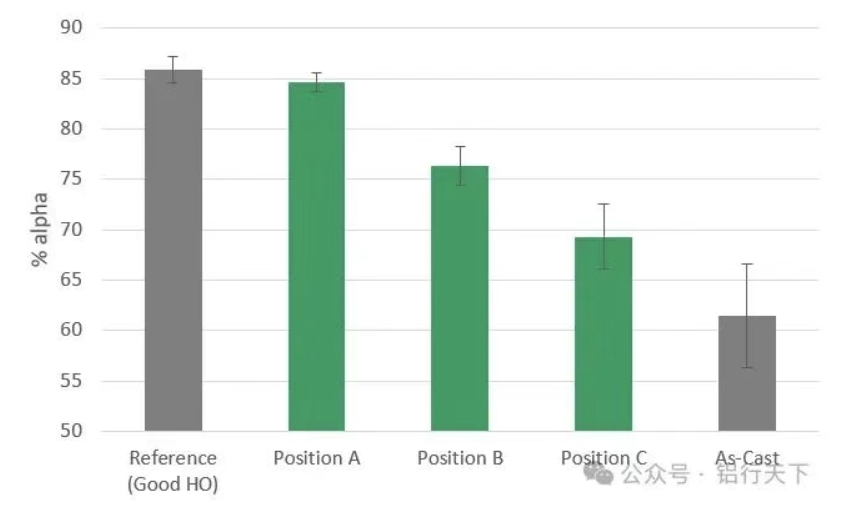

Daim duab 5 qhia ib qho piv txwv ntawm kev siv cov ntaub ntawv no li cas. Hauv qhov no, cov txiaj ntsig tau qhia tias cov cua sov tsis sib xws hauv ib lub qhov cub tshwj xeeb, lossis tej zaum qhov ntsuas kub tsis ncav cuag. Txhawm rau soj ntsuam cov xwm txheej zoo li no, ob qho tib si kev sim billet thiab cov ntawv siv hluav taws xob uas paub zoo yuav tsum tau ua. Yog tsis muaj cov no, qhov xav tau % α ntau yam rau qhov sib xyaw alloy tsis tuaj yeem tsim.

Fig. 5. Kev sib piv ntawm % α nyob rau hauv qhov sib txawv ntawm qhov ua tau zoo homogenization rauv.

Post lub sij hawm: Aug-30-2025