1. Taw qhia

Aluminium alloys nrog lub zog nruab nrab muaj cov yam ntxwv ua tau zoo, quenching rhiab heev, cuam tshuam toughness, thiab corrosion kuj. Lawv feem ntau ua haujlwm nyob rau hauv ntau yam lag luam, xws li electronics thiab marine, rau kev tsim cov kav dej, pas nrig, profiles, thiab cov xov hlau. Tam sim no, muaj kev xav tau ntau ntxiv rau 6082 aluminium alloy tuav. Txhawm rau ua kom tau raws li kev lag luam xav tau thiab cov neeg siv yuav tsum tau ua, peb tau ua cov kev sim ntawm cov txheej txheem sib txawv ntawm cov cua kub extrusion thiab cov txheej txheem kho cua sov zaum kawg rau 6082-T6 tuav. Peb lub hom phiaj yog txhawm rau txheeb xyuas cov txheej txheem kev kho cua sov uas ua kom tau raws li qhov xav tau ntawm kev ua haujlwm zoo rau cov kab no.

2.Kev sim cov khoom siv thiab cov txheej txheem ntau lawm

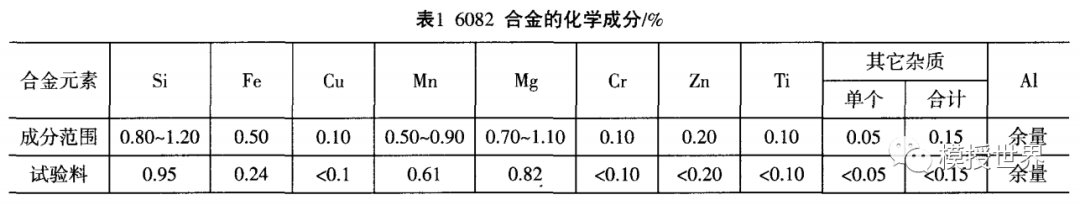

2.1 Cov khoom siv sim

Casting ingots ntawm qhov loj me Ф162 × 500 tau tsim los siv ib txoj kev nruam nruam thiab raug kev kho tsis zoo. Lub metallurgical zoo ntawm cov ingots ua raws li lub tuam txhab kev tswj kev tswj cov qauv. Cov tshuaj muaj pes tsawg leeg ntawm 6082 alloy yog qhia hauv Table 1.

2.2 Cov txheej txheem ntau lawm

Qhov kev sim 6082 bar muaj qhov tshwj xeeb ntawm Ф14mm. Lub thawv extrusion muaj ib txoj kab uas hla ntawm Ф170mm nrog 4-qhov extrusion tsim thiab extrusion coefficient ntawm 18.5. Cov txheej txheem tshwj xeeb muaj xws li cua sov lub ingot, extrusion, quenching, stretching straightening thiab sampling, roller straightening, zaum kawg txiav, dag aging, zoo soj ntsuam, thiab xa.

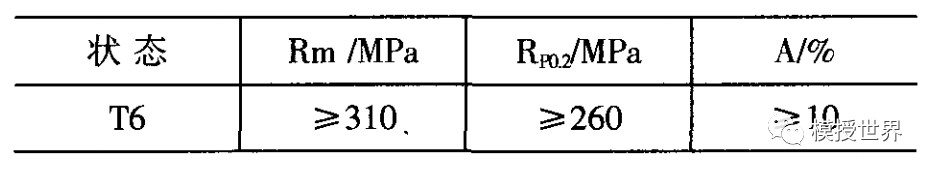

3. Kev sim Lub Hom Phiaj

Lub hom phiaj ntawm txoj kev tshawb no yog txhawm rau txheeb xyuas cov txheej txheem kev kho cua sov extrusion thiab cov kev kho cua sov zaum kawg uas cuam tshuam rau kev ua haujlwm ntawm 6082-T6 tuav, thaum kawg ua tiav cov qauv kev ua haujlwm. Raws li cov qauv, lub longitudinal mechanical zog ntawm 6082 alloy yuav tsum tau raws li cov specifications teev nyob rau hauv Table 2.

4. Kev sim ua kom zoo

4.1 Extrusion Heat Treatment Investigation

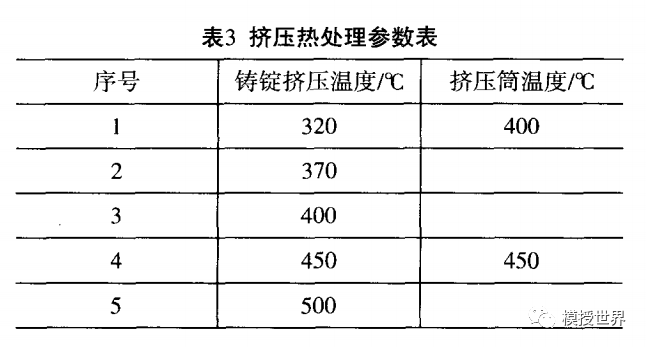

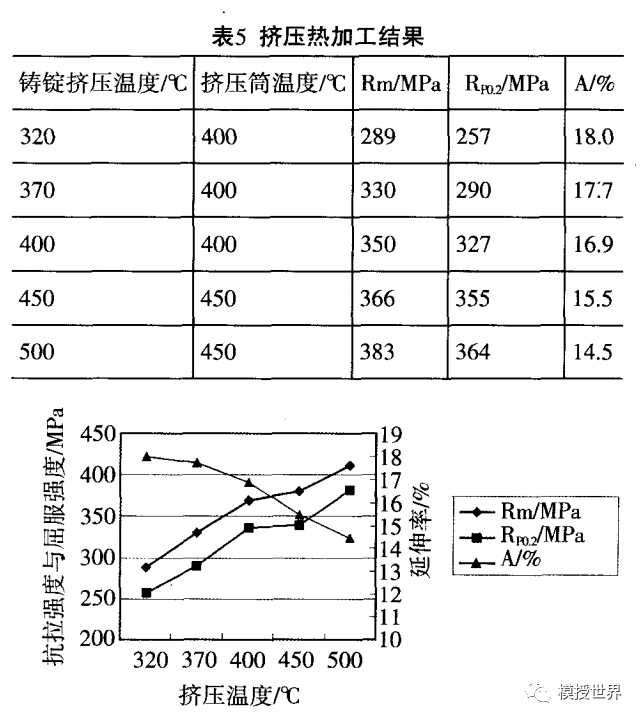

Kev tshawb nrhiav kev kho cua sov extrusion feem ntau tsom rau qhov cuam tshuam ntawm casting ingot extrusion kub thiab extrusion thawv kub ntawm cov khoom siv tshuab. Cov kev xaiv tshwj xeeb tau piav qhia hauv Table 3.

4.2 Kev Soj Ntsuam thiab Kev Tshawb Fawb Kev Kub Kub Kub Kub Kub

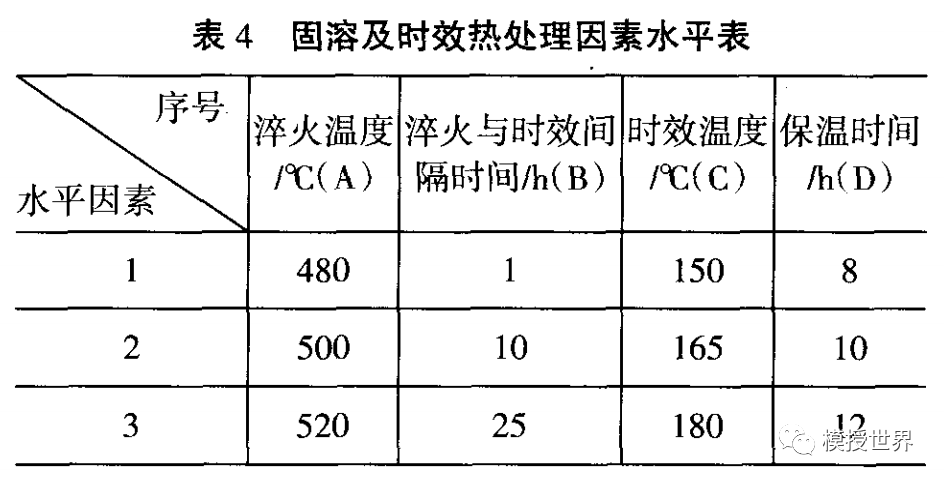

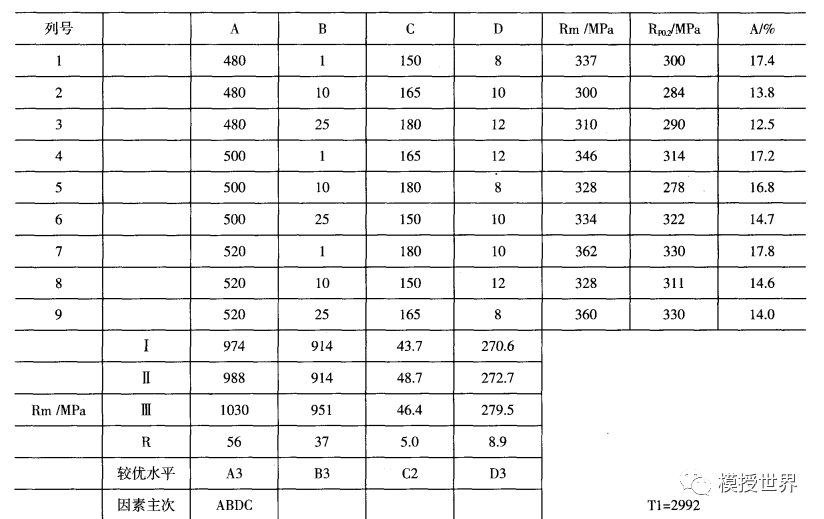

Ib qho kev sim orthogonal tau ua haujlwm rau cov khoom siv tshuaj thiab cov txheej txheem kev kho cua sov. Cov theem uas tau xaiv yog muab nyob rau hauv Table 4, nrog rau lub rooj tsim orthogonal denoted li IJ9(34).

5.Qhov tshwm sim thiab kev tshuaj xyuas

5.1 Extrusion Heat Treatment Experiment Results thiab Analysis

Cov txiaj ntsig ntawm kev sim kev kho cua sov extrusion tau nthuav tawm hauv Table 5 thiab daim duab 1. Cuaj qhov qauv raug coj los rau txhua pab pawg, thiab lawv qhov nruab nrab ntawm kev ua haujlwm tau raug txiav txim siab. Raws li kev txheeb xyuas metallographic thiab tshuaj muaj pes tsawg leeg, kev kho cua sov tau tsim: quenching ntawm 520 ° C rau 40 feeb thiab kev laus ntawm 165 ° C rau 12 teev. Los ntawm Table 5 thiab daim duab 1, nws tuaj yeem pom tau tias vim qhov kub thiab txias ntawm cov khoom siv extrusion tau nce, ob qho tib si tensile lub zog thiab lub zog tawm los maj mam nce. Cov txiaj ntsig zoo tshaj plaws tau txais ntawm extrusion kub ntawm 450-500 ° C thiab extrusion thawv kub ntawm 450 ° C, uas ua tau raws li tus qauv yuav tsum tau ua. Qhov no yog vim qhov tshwm sim ntawm kev ua haujlwm txias txias ntawm qhov qis extrusion kub, ua rau cov qoob loo ntawm cov ciam teb tawg thiab nce cov kua dej decomposition ntawm A1 thiab Mn thaum cua sov ua ntej quenching, ua rau recrystallization. Raws li qhov kub extrusion nce, qhov kawg lub zog Rm ntawm cov khoom no ho txhim kho. Thaum lub thawv extrusion kub los yog tshaj qhov kub ntawm qhov kub, qhov tsis sib xws ntawm deformation txo, txo qhov tob ntawm coarse grain rings thiab nce lub zog tawm los Rm. Yog li, qhov tsim nyog rau kev kho cua sov extrusion yog: ingot extrusion kub ntawm 450-500 ° C thiab extrusion thawv kub ntawm 430-450 ° C.

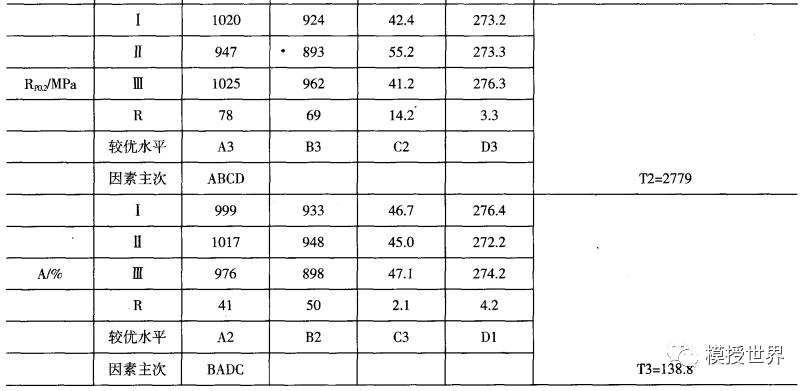

5.2 Kev daws teeb meem thiab Kev Laus Orthogonal Kev Tshawb Fawb Kev Tshawb Fawb thiab Kev Tshawb Fawb

Table 6 qhia tias qhov zoo tshaj plaws qib yog A3B1C2D3, nrog quenching ntawm 520 ° C, dag aging kub ntawm 165-170 ° C, thiab aging ncua sij hawm ntawm 12 teev, ua rau muaj zog thiab plasticity ntawm cov tuav. Cov txheej txheem quenching ua cov tshuaj supersaturated. Thaum qis quenching kub, qhov concentration ntawm supersaturated solid tov txo, cuam tshuam lub zog. Lub quenching kub ntawm ib ncig ntawm 520 ° C ho txhim khu cov nyhuv ntawm quenching-induced solid tov ntxiv zog. Lub caij nyoog nruab nrab ntawm quenching thiab dag aging, piv txwv li, chav tsev kub cia, zoo heev influences mechanical zog. Qhov no tshwj xeeb tshaj yog rau cov pas nrig uas tsis ncab tom qab quenching. Thaum lub sij hawm nruab nrab ntawm quenching thiab aging tshaj 1 teev, lub zog, tshwj xeeb tshaj yog tawm los lub zog, txo qis.

5.3 Metallographic Microstructure Analysis

High-magnification thiab polarized tsom xam tau ua nyob rau ntawm 6082-T6 tuav ntawm cov khoom kub ntawm 520 ° C thiab 530 ° C. High-magnification duab qhia cov xim sib xyaw ua ke nag lossis daus nrog ntau precipitate theem hais tusyees faib. Polarized lub teeb tsom xam siv Axiovert200 cov cuab yeej tau pom qhov sib txawv ntawm cov qauv duab duab. Lub hauv paus cheeb tsam tau nthuav tawm cov nplej me me thiab tsis sib xws, thaum cov npoo nthuav tawm qee qhov recrystallization nrog elongated nplej. Qhov no yog vim qhov kev loj hlob ntawm crystal nuclei ntawm qhov kub thiab txias, ua rau cov koob ntxhib zoo li precipitates.

6.Production Practice Assessment

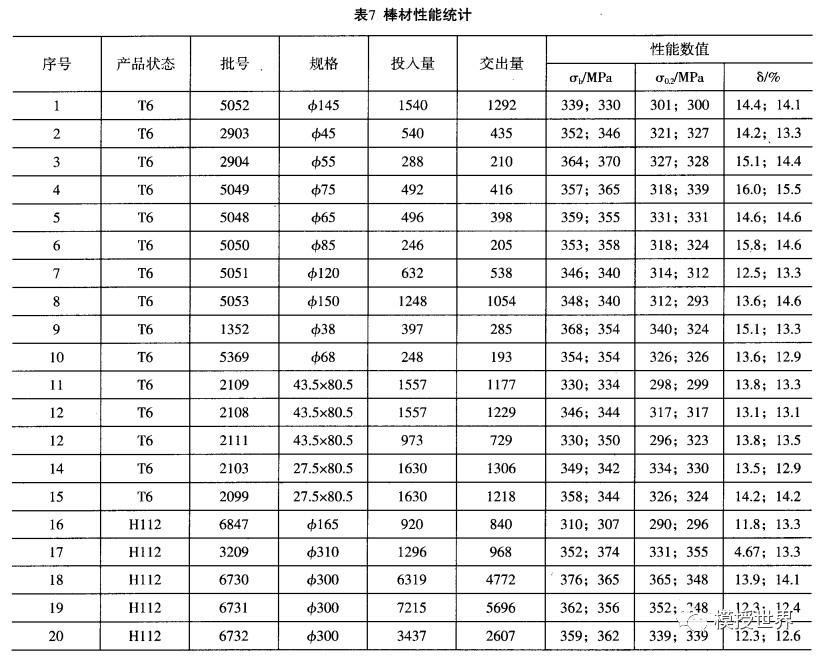

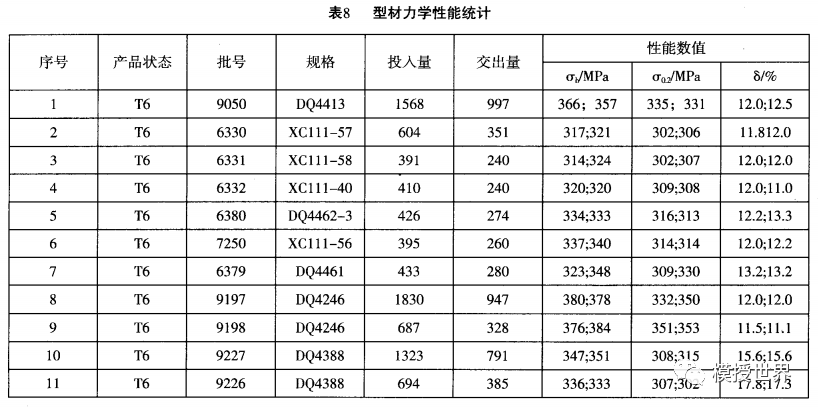

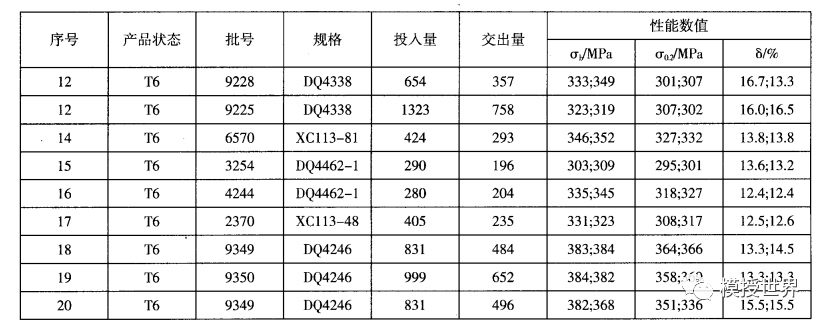

Hauv kev tsim khoom tiag tiag, kev txheeb xyuas kev ua haujlwm tau ua tiav ntawm 20 pawg ntawm cov tuav thiab 20 pawg ntawm cov profiles. Cov txiaj ntsig tau pom nyob rau hauv Cov Lus 7 thiab 8. Hauv kev tsim khoom tiag tiag, peb cov txheej txheem extrusion tau ua nyob rau ntawm qhov kub thiab txias uas ua rau T6 lub xeev cov qauv, thiab kev ua haujlwm ntawm cov tshuab ua tau raws li lub hom phiaj tseem ceeb.

7. Cov lus xaus

(1) Extrusion kub kho tsis: Ingots extrusion kub ntawm 450-500 ° C; extrusion thawv kub ntawm 430-450 ° C.

(2) Kev kho cua sov zaum kawg: Qhov zoo tshaj plaws kev daws teeb meem kub ntawm 520-530 ° C; Kev laus kub ntawm 165 ± 5 ° C, kev laus lub sijhawm ntawm 12 teev; Lub sijhawm nruab nrab ntawm quenching thiab aging yuav tsum tsis pub tshaj 1 teev.

(3) Raws li kev ntsuam xyuas, cov txheej txheem kho cua sov siv tau suav nrog: extrusion kub ntawm 450-530 ° C, extrusion thawv kub ntawm 400-450 ° C; Cov kua dej kub ntawm 510-520 ° C; aging kev tswj ntawm 155-170 ° C rau 12 teev; tsis muaj kev txwv tshwj xeeb rau lub caij nyoog ntawm quenching thiab aging. Qhov no tuaj yeem muab tso rau hauv cov txheej txheem kev ua haujlwm.

Kho los ntawm May Jiang los ntawm MAT Aluminium

Lub sij hawm xa tuaj: Mar-15-2024