Thaum lub sij hawm extrusion txheej txheem ntawm txhuas alloy extruded cov ntaub ntawv, tshwj xeeb tshaj yog txhuas profiles, ib tug "pitting" tsis xws luag feem ntau tshwm sim nyob rau saum npoo. Cov kev tshwm sim tshwj xeeb suav nrog cov qog me me uas muaj qhov sib txawv ntawm qhov sib txawv, tailing, thiab pom tseeb txhais tes, nrog lub siab xav. Tom qab oxidation los yog electrophoretic nto kho, lawv feem ntau tshwm raws li dub granules adhering rau saum npoo ntawm cov khoom.

Nyob rau hauv lub extrusion zus tau tej cov loj-section profiles, qhov tsis xws luag no feem ntau yuav tshwm sim los ntawm tus yam ntxwv ntawm lub ingot qauv, extrusion kub, extrusion ceev, pwm complexity, thiab lwm yam cov khoom kawg.

Hauv cov khoom siv lub qhov rooj thiab qhov rais zoo tib yam, cov neeg siv khoom feem ntau lees txais qhov tsis xws luag me me, tab sis rau cov khoom lag luam uas xav tau kev sib npaug ntawm cov khoom siv kho kom zoo nkauj thiab kev ua haujlwm zoo nkauj lossis ntau qhov tseem ceeb ntawm kev ua haujlwm zoo nkauj, cov neeg siv khoom feem ntau tsis lees txais qhov tsis xws luag, tshwj xeeb tshaj yog pitted defects uas tsis sib haum nrog cov xim sib txawv.

Txhawm rau txheeb xyuas cov txheej txheem tsim ntawm cov khoom ntxhib, morphology thiab muaj pes tsawg leeg ntawm qhov chaw tsis xws luag nyob rau hauv cov txheej txheem sib txawv alloy thiab extrusion txheej txheem tau txheeb xyuas, thiab qhov sib txawv ntawm qhov tsis xws luag thiab cov matrix tau muab piv. Ib qho kev daws teeb meem tsim nyog los daws cov teeb meem ntxhib tau muab tso rau pem hauv ntej, thiab kev sim sim tau ua tiav.

Yuav kom daws tau qhov tsis xws luag ntawm pitting profiles, nws yog ib qho tsim nyog yuav tsum nkag siab qhov tsim mechanism ntawm pitting tsis xws luag. Thaum lub sij hawm extrusion txheej txheem, aluminium sticking rau tuag ua hauj lwm txoj siv yog lub ntsiab ua rau pitting tsis xws luag nyob rau saum npoo ntawm extruded txhuas cov ntaub ntawv. Qhov no yog vim hais tias cov txheej txheem extrusion ntawm txhuas yog nqa tawm ntawm qhov kub ntawm txog 450 ° C. Yog tias qhov cuam tshuam ntawm deformation tshav kub thiab kev sib txhuam kub ntxiv, qhov kub ntawm cov hlau yuav siab dua thaum nws ntws tawm ntawm qhov tuag. Thaum cov khoom ntws tawm ntawm qhov tuag qhov tuag, vim qhov kub thiab txias, muaj qhov tshwm sim ntawm aluminium sticking ntawm cov hlau thiab cov pwm ua haujlwm.

Daim ntawv ntawm kev sib koom ua ke no feem ntau: kev rov ua dua ntawm kev sib koom ua ke - tearing - bonding - tearing dua, thiab cov khoom ntws mus rau pem hauv ntej, ua rau ntau qhov me me ntawm cov khoom.

Qhov kev sib koom ua ke no muaj feem xyuam nrog rau yam xws li qhov zoo ntawm lub ingot, qhov chaw ntawm cov pwm ua hauj lwm txoj siv, extrusion kub, extrusion ceev, degree ntawm deformation, thiab deformation kuj ntawm cov hlau.

1 Cov ntaub ntawv xeem thiab cov txheej txheem

Los ntawm kev tshawb fawb ua ntej, peb tau kawm tias yam xws li metallurgical purity, pwm txheej txheem, txheej txheem extrusion, cov khoom xyaw, thiab cov khoom tsim tawm tuaj yeem cuam tshuam rau qhov chaw roughened hais. Hauv kev sim, ob lub alloy rods, 6005A thiab 6060, tau siv los extrud tib seem. Lub morphology thiab muaj pes tsawg leeg ntawm roughened particle txoj hauj lwm tau soj ntsuam los ntawm kev nyeem ntawv ncaj qha spectrometer thiab SEM nrhiav kom tau txoj kev, thiab muab piv nrog rau ib puag ncig matrix.

Txhawm rau kom paub meej qhov txawv ntawm morphology ntawm ob qhov tsis xws luag ntawm pitted thiab hais, lawv tau txhais raws li hauv qab no:

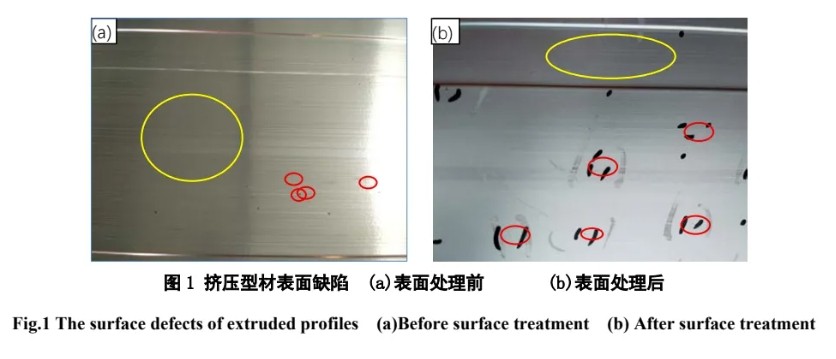

(1) Pitted defects los yog rub defects yog ib yam ntawm cov ntsiab lus tsis xws luag uas yog ib qho tsis xwm yeem tadpole-zoo li los yog taw tes-zoo li khawb qhov tsis xws luag uas tshwm rau saum npoo ntawm qhov profile. Qhov tsis xws luag pib los ntawm kos kab txaij thiab xaus nrog qhov tsis xws luag ntog, accumulating rau hauv hlau taum ntawm qhov kawg ntawm kab kos. Qhov loj ntawm qhov pitted tsis xws luag yog feem ntau 1-5 hli, thiab nws tig dub dub tom qab oxidation kev kho mob, uas thaum kawg cuam tshuam cov tsos ntawm cov profile, raws li qhia nyob rau hauv lub liab lub voj voog nyob rau hauv daim duab 1.

(2) Cov khoom saum npoo kuj hu ua hlau taum lossis cov khoom adsorption. Qhov saum npoo ntawm aluminium alloy profile yog txuas nrog spherical grey-dub nyuaj hlau hais thiab muaj cov qauv xoob. Muaj ob hom aluminium alloy profiles: cov uas tuaj yeem wiped tawm thiab cov uas tsis tuaj yeem wiped tawm. Qhov loj yog feem ntau tsawg dua 0.5mm, thiab nws xav tias ntxhib rau qhov kov. Tsis muaj khawb hauv pem hauv ntej. Tom qab oxidation, nws tsis txawv ntau ntawm cov matrix, raws li qhia hauv lub voj voog daj hauv daim duab 1.

2 Kev ntsuam xyuas thiab kev soj ntsuam

2.1 Nto rub defects

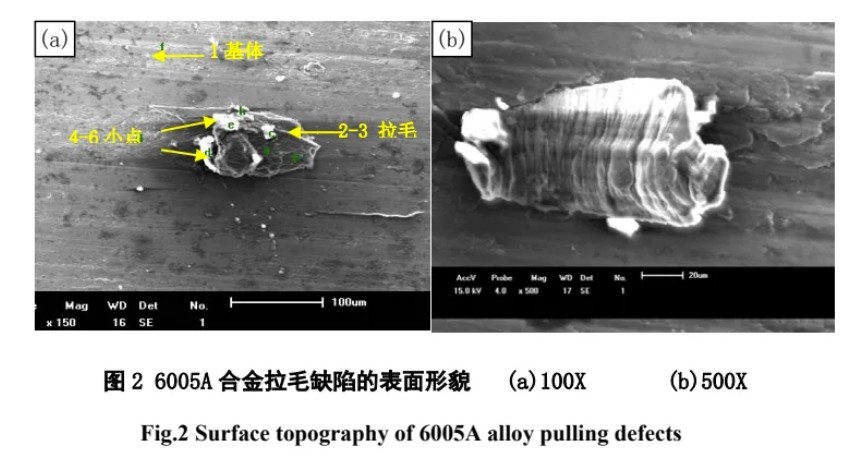

Daim duab 2 qhia tau hais tias lub microstructural morphology ntawm kev rub tsis xws luag ntawm qhov chaw ntawm 6005A alloy. Muaj cov kauj ruam zoo li khawb nyob rau hauv pem hauv ntej ntawm rub, thiab lawv xaus nrog stacked nodules. Tom qab cov nodules tshwm sim, qhov saum npoo rov qab zoo li qub. Qhov chaw ntawm roughening tsis xws luag yog tsis du rau qhov kov, muaj ib tug ntse pos xav, thiab adheres los yog accumulates nyob rau saum npoo ntawm qhov profile. Los ntawm kev xeem extrusion, nws tau pom tias rub morphology ntawm 6005A thiab 6060 extruded profiles zoo ib yam, thiab tus Tsov tus tw kawg ntawm cov khoom yog ntau tshaj lub taub hau kawg; qhov sib txawv yog tias tag nrho rub loj ntawm 6005A yog me dua thiab khawb qhov tob tsis muaj zog. Qhov no tej zaum yuav muaj feem xyuam rau cov kev hloov ntawm cov hlau alloy, cam khwb cia pas nrig xeev, thiab pwm tej yam kev mob. Pom nyob rau hauv 100X, muaj qhov pom tseeb kos cim rau ntawm qhov kawg ntawm qhov rub qhov chaw, uas yog elongated raws cov kev taw qhia extrusion, thiab cov duab ntawm qhov kawg nodule hais tsis xwm yeem. Ntawm 500X, sab pem hauv ntej kawg ntawm qhov rub tawm muaj cov kauj ruam zoo li khawb raws li qhov kev taw qhia extrusion (qhov loj ntawm qhov tsis xws luag yog li ntawm 120 μm), thiab muaj cov cim pom tseeb ntawm cov khoom nodular ntawm tus Tsov tus tw kawg.

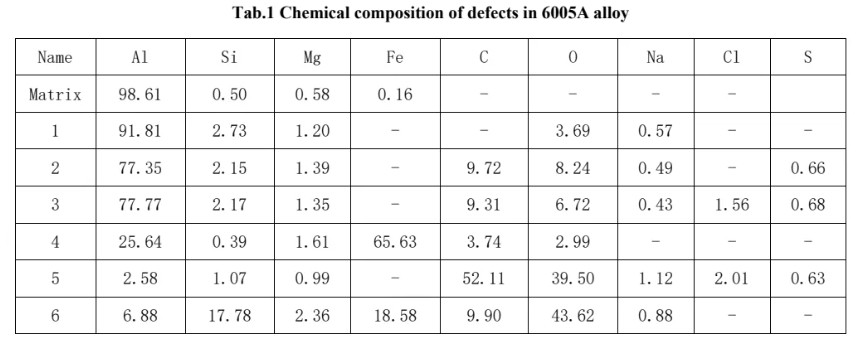

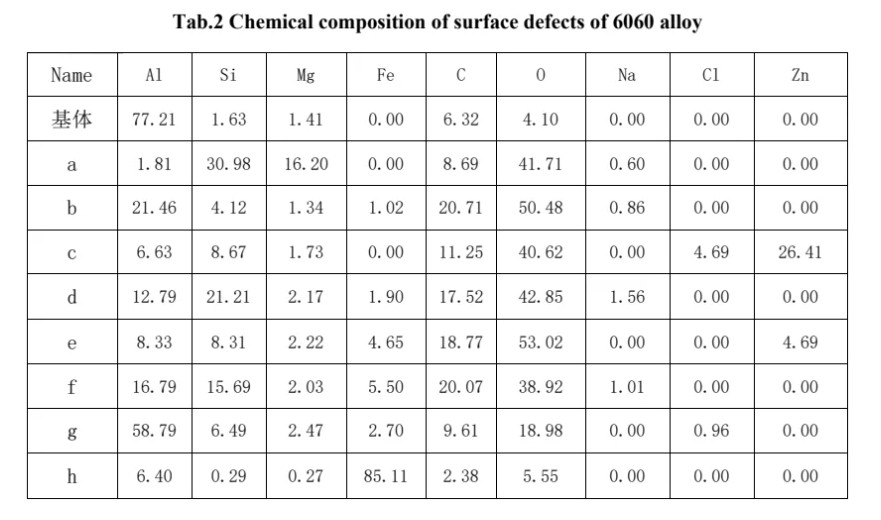

Txhawm rau txheeb xyuas qhov ua rau rub, kev nyeem ncaj qha spectrometer thiab EDX tau siv los ua cov tshuaj ntsuam xyuas ntawm qhov chaw tsis raug thiab matrix ntawm peb cov khoom siv alloy. Table 1 qhia cov txiaj ntsig ntawm 6005A profile. Cov txiaj ntsig EDX qhia tau hais tias muaj pes tsawg leeg ntawm txoj haujlwm stacking ntawm cov khoom rub tawm yog qhov pib zoo ib yam li cov matrix. Tsis tas li ntawd, qee qhov tsis zoo impurity yog sau nyob rau hauv thiab ib ncig ntawm lub rub tawm, thiab cov impurity hais muaj C, O (los yog Cl), los yog Fe, Si, thiab S.

Kev soj ntsuam ntawm qhov tsis xws luag roughening ntawm 6005A nplua oxidized extruded profiles qhia tau hais tias cov khoom rub tawm yog loj loj (1-5mm), qhov saum npoo feem ntau yog stacked, thiab muaj cov kauj ruam zoo li khawb ntawm sab pem hauv ntej; Cov muaj pes tsawg leeg yog nyob ze rau Al matrix, thiab yuav muaj heterogeneous theem uas muaj Fe, Si, C, thiab O faib nyob ib ncig ntawm nws. Nws qhia tau hais tias lub rub tsim mechanism ntawm peb alloys yog tib yam.

Thaum lub sij hawm extrusion txheej txheem, hlau ntws kev sib txhuam yuav ua rau qhov kub ntawm cov pwm ua hauj lwm txoj siv yuav nce, ua ib tug "nplaum txhuas txheej" nyob rau hauv lub txiav ntug ntawm txoj siv ua hauj lwm nkag. Nyob rau tib lub sijhawm, ntau dhau Si thiab lwm cov ntsiab lus xws li Mn thiab Cr hauv aluminium alloy yog ib qho yooj yim los tsim cov kev hloov khoom siv nrog Fe, uas yuav txhawb kev tsim cov "nplaum txhuas txheej" ntawm qhov nkag ntawm qhov chaw ua haujlwm pwm.

Raws li cov hlau ntws mus rau pem hauv ntej thiab rub tawm ntawm txoj siv sia ua haujlwm, qhov tshwm sim ntawm kev sib txuas ntawm kev sib txuas txuas ntxiv-tearing-bonding tshwm sim ntawm qee txoj haujlwm, ua rau cov hlau tsis tu ncua ntawm txoj haujlwm no. Thaum cov khoom nce mus rau qhov loj me, Nws yuav raug rub tawm los ntawm cov khoom ntws thiab tsim cov cim kos rau ntawm cov hlau nto. Nws yuav nyob twj ywm rau ntawm qhov chaw hlau thiab daim ntawv rub tawm ntawm qhov kawg ntawm khawb. Yog li ntawd, nws tuaj yeem txiav txim siab tias qhov tsim ntawm roughened hais yog feem ntau cuam tshuam nrog aluminium sticking rau pwm ua haujlwm siv. Lub heterogeneous theem faib nyob ib ncig ntawm nws tej zaum yuav pib los ntawm lubricating roj, oxides los yog plua plav hais, nrog rau impurities coj los ntawm cov ntxhib nto ntawm lub ingot.

Txawm li cas los xij, tus naj npawb ntawm rub tawm hauv 6005A qhov kev xeem tau tsawg dua thiab qhov degree yog sib dua. Ntawm qhov tod tes, nws yog vim lub chamfering ntawm qhov tawm ntawm cov pwm ua haujlwm txoj siv thiab ua tib zoo polishing ntawm txoj siv sia ua haujlwm kom txo tau cov thickness ntawm txhuas txheej; ntawm qhov tod tes, nws muaj feem xyuam rau cov ntsiab lus Si ntau dhau.

Raws li kev nyeem ntawv ncaj qha spectral muaj pes tsawg leeg cov txiaj ntsig, nws tuaj yeem pom tias ntxiv rau Si ua ke nrog Mg Mg2Si, qhov seem Si tshwm nyob rau hauv daim ntawv ntawm cov khoom siv yooj yim.

2.2 Cov khoom me me ntawm qhov chaw

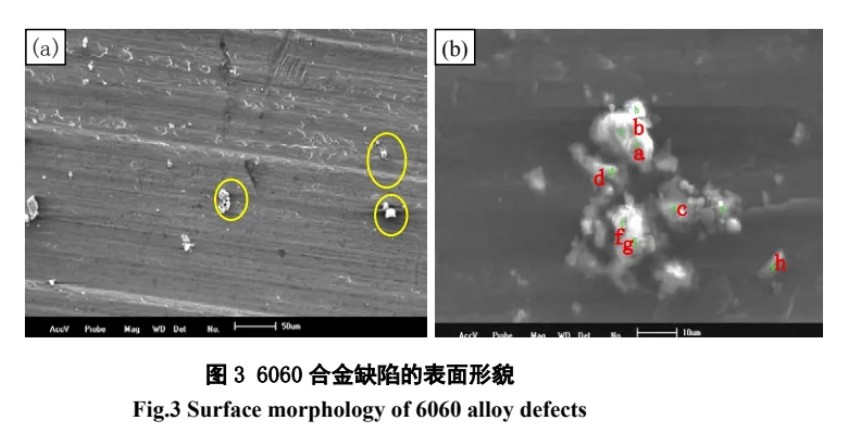

Nyob rau hauv kev tshuaj ntsuam xyuas qhov muag pom tsawg tsawg, cov khoom me me (≤0.5mm), tsis du rau qhov kov, muaj lub siab zoo, thiab ua raws li qhov profile. Pom nyob rau hauv 100X, cov khoom me me ntawm qhov chaw tau muab faib ua ntu zus, thiab muaj cov khoom me me txuas rau saum npoo tsis hais seb puas muaj khawb los yog tsis;

Ntawm 500X, tsis muaj teeb meem seb puas muaj qhov pom tseeb zoo li khawb ntawm qhov chaw raws li kev coj ua extrusion, ntau cov khoom tseem txuas nrog, thiab qhov sib txawv me me. Qhov loj tshaj particle loj yog hais txog 15 μm, thiab cov khoom me me yog li 5 μm.

Los ntawm kev txheeb xyuas muaj pes tsawg leeg ntawm 6060 alloy nto cov khoom thiab cov matrix tsis zoo, cov khoom feem ntau yog tsim los ntawm O, C, Si, thiab Fe cov ntsiab lus, thiab cov ntsiab lus txhuas yog tsawg heev. Yuav luag tag nrho cov khoom muaj cov ntsiab lus O thiab C. Cov muaj pes tsawg leeg ntawm txhua qhov sib txawv me ntsis. Ntawm lawv, ib tug hais nyob ze rau 10 μm, uas yog ho siab tshaj matrix Si, Mg, thiab O; Hauv c particles, Si, O, thiab Cl yog pom tseeb dua; Particle d thiab f muaj Si, O, thiab Na; e muaj Si, Fe, thiab O; h particles yog Fe-muaj cov khoom xyaw. Cov txiaj ntsig ntawm 6060 cov ntsiab lus zoo ib yam li qhov no, tab sis vim tias Si thiab Fe cov ntsiab lus hauv 6060 nws tus kheej qis, cov ntsiab lus Si thiab Fe sib xws hauv cov khoom saum npoo kuj tsawg; C cov ntsiab lus nyob rau hauv 6060 hais yog qhov tsawg.

Cov khoom saum npoo tej zaum yuav tsis yog ib qho me me, tab sis kuj tseem tuaj yeem muaj nyob rau hauv daim ntawv ntawm kev sib sau ntawm ntau cov khoom me me nrog cov duab sib txawv, thiab cov feem pua ntawm cov ntsiab lus sib txawv hauv cov khoom sib txawv. Nws ntseeg tau hais tias cov khoom yog tsim los ntawm ob hom. Ib qho yog precipitates xws li AlFeSi thiab elemental Si, uas yog los ntawm cov theem siab melting point impurity xws li FeAl3 los yog AlFeSi (Mn) nyob rau hauv lub ingot, los yog precipitate theem thaum lub sij hawm extrusion txheej txheem. Lwm qhov yog adherent txawv teb chaws teeb meem.

2.3 Qhov cuam tshuam ntawm qhov roughness ntawm ingot

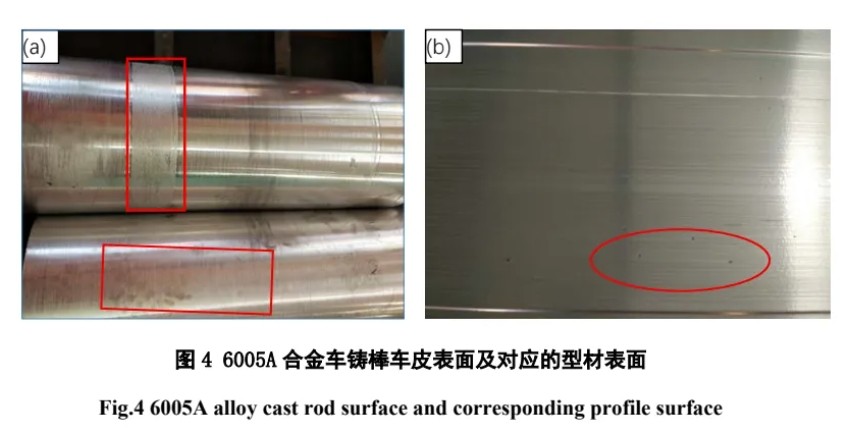

Thaum lub sij hawm kev sim, nws tau pom tias tom qab nto ntawm 6005A cam khwb cia pas nrig tshuab dhos yog ntxhib thiab stained nrog hmoov av. Muaj ob lub cam khwb cia nrog qhov sib sib zog nqus tig cov cuab yeej ntawm cov chaw hauv zos, uas sib haum mus rau qhov nce ntxiv ntawm cov rub tawm tom qab extrusion, thiab qhov loj ntawm ib qho rub tawm loj dua, raws li qhia hauv daim duab 7.

6005A cam khwb cia pas nrig tsis muaj tshuab dhos, yog li qhov roughness ntawm qhov chaw yog tsawg thiab tus naj npawb ntawm rub tawm. Tsis tas li ntawd, vim tias tsis muaj cov kua dej ntau dhau txuas nrog lub tshuab dhos cov cim ntawm cov cam khwb cia, cov ntsiab lus C hauv cov khoom sib thooj raug txo. Nws tau raug pov thawj tias cov qhab nia ntawm qhov chaw ntawm cov pas nrig cam khwb cia yuav aggravate rub thiab particle tsim rau ib qho twg.

3 Kev sib tham

(1) Cov khoom ntawm rub cov teeb meem yog qhov pib zoo ib yam li cov matrix. Nws yog cov khoom txawv teb chaws, cov tawv nqaij qub nyob rau saum npoo ntawm lub ingot thiab lwm yam impurities sau nyob rau hauv lub extrusion chim phab ntsa los yog qhov chaw tuag ntawm pwm thaum lub sij hawm extrusion txheej txheem, uas yog coj mus rau lub hlau nto los yog txhuas txheej ntawm pwm ua hauj lwm txoj siv. Raws li cov khoom ntws mus rau pem hauv ntej, nto khawb yog tshwm sim, thiab thaum cov khoom sib sau ua ke rau ib qho me me, nws raug tshem tawm los ntawm cov khoom los tsim rub tawm. Tom qab oxidation, lub rub tau corroded, thiab vim nws qhov loj me, muaj qhov tsis xws luag nyob rau ntawd.

(2) Cov khoom saum npoo qee zaum tshwm sim raws li ib qho me me, thiab qee zaum muaj nyob hauv daim ntawv sib sau. Lawv muaj pes tsawg leeg yog pom tseeb txawv ntawm cov matrix, thiab feem ntau muaj O, C, Fe, thiab Si ntsiab. Qee qhov ntawm cov ntsiab lus yog tswj hwm los ntawm O thiab C cov ntsiab lus, thiab qee qhov hais tawm los ntawm O, C, Fe, thiab Si. Yog li ntawd, nws yog inferred hais tias cov deg hais los ntawm ob qhov chaw: ib tug yog precipitates xws li AlFeSi thiab elemental Si, thiab impurities xws li O thiab C yog adhered rau saum npoo; Lwm qhov yog adherent txawv teb chaws teeb meem. Cov khoom yog corroded tam sim ntawd tom qab oxidation. Vim lawv qhov me me, lawv tsis muaj kev cuam tshuam me me rau ntawm qhov chaw.

(3) Cov khoom nplua nuj nyob hauv C thiab O cov ntsiab lus feem ntau yog los ntawm cov roj lubricating, plua plav, av, huab cua, thiab lwm yam. Cov khoom tseem ceeb ntawm cov roj lubricating yog C, O, H, S, thiab lwm yam, thiab cov khoom tseem ceeb ntawm plua plav thiab av yog SiO2. Cov ntsiab lus O ntawm cov khoom saum npoo yog feem ntau siab. Vim tias cov khoom nyob rau hauv qhov kub thiab txias tam sim ntawd tom qab tawm hauv txoj siv sia, thiab vim qhov loj ntawm qhov chaw ntawm cov khoom, lawv yooj yim adsorb O atoms hauv huab cua thiab ua rau oxidation tom qab kev sib cuag nrog huab cua, ua rau muaj O cov ntsiab lus ntau dua li cov matrix.

(4) Fe, Si, thiab lwm yam feem ntau yog los ntawm cov oxides, qub nplai thiab impurity theem nyob rau hauv lub ingot (siab melting point los yog theem thib ob uas tsis tag nrho tshem tawm los ntawm homogenization). Lub Fe lub hauv paus pib los ntawm Fe nyob rau hauv txhuas ingots, tsim siab melting point impurity theem xws li FeAl3 los yog AlFeSi (Mn), uas tsis tuaj yeem yaj nyob rau hauv cov khoom tov thaum lub sij hawm homogenization txheej txheem, los yog tsis tag nrho hloov dua siab tshiab; Si muaj nyob rau hauv txhuas matrix nyob rau hauv daim ntawv ntawm Mg2Si los yog ib tug supersaturated khoom tov ntawm Si thaum lub sij hawm casting txheej txheem. Thaum lub sij hawm kub extrusion txheej txheem ntawm cam khwb cia pas nrig, tshaj Si yuav precipitate. Solubility ntawm Si hauv txhuas yog 0.48% ntawm 450 ° C thiab 0.8% (wt%) ntawm 500 ° C. Cov ntsiab lus Si ntau dhau hauv 6005 yog kwv yees li 0.41%, thiab nag lossis daus Si tuaj yeem yog kev sib sau ua ke thiab nag lossis daus los ntawm qhov sib txawv ntawm qhov concentration.

(5) Aluminium sticking rau pwm ua hauj lwm txoj siv yog lub ntsiab ua rau rub. Lub extrusion tuag yog qhov kub thiab txias ib puag ncig. Hlau ntws kev sib txhuam yuav ua rau kom qhov kub thiab txias ntawm txoj siv sia ua haujlwm ntawm cov pwm, tsim "txheej txhuas txheej" ntawm qhov txiav ntawm txoj siv txoj siv nkag.

Nyob rau tib lub sijhawm, ntau dhau Si thiab lwm cov ntsiab lus xws li Mn thiab Cr hauv aluminium alloy yog ib qho yooj yim los tsim cov kev hloov khoom siv nrog Fe, uas yuav txhawb kev tsim cov "nplaum txhuas txheej" ntawm qhov nkag ntawm qhov chaw ua haujlwm pwm. Cov hlau ntws los ntawm "cov nplaum nplaum" yog nyob rau hauv kev sib txhuam sab hauv (sliding shear hauv cov hlau). Cov hlau deforms thiab hardens vim muaj kev sib txhuam sab hauv, uas txhawb nqa cov hlau hauv qab thiab cov pwm kom lo ua ke. Nyob rau tib lub sijhawm, cov pwm ua haujlwm txoj siv yog deformed rau hauv cov duab trumpet vim lub siab, thiab cov nplaum nplaum tsim los ntawm kev txiav ntug ib feem ntawm txoj siv sia ua haujlwm hu rau qhov profile zoo ib yam li kev txiav ntug ntawm lub cuab yeej tig.

Kev tsim cov nplaum nplaum yog cov txheej txheem dynamic ntawm kev loj hlob thiab ua kom tawg. Cov khoom yog tas li raug coj tawm los ntawm qhov profile.Adhere rau saum npoo ntawm qhov profile, sib sau rub tawm qhov tsis xws luag. Yog tias nws ntws ncaj qha tawm ntawm txoj siv sia ua haujlwm thiab tam sim ntawd adsorbed rau ntawm qhov profile, cov khoom me me thermally adhered rau saum npoo yog hu ua "adsorption particles". Yog tias qee cov khoom yuav raug tawg los ntawm extruded aluminium alloy, qee cov khoom yuav lo rau ntawm qhov chaw ua haujlwm ntawm txoj siv sia thaum hla txoj siv sia, ua rau khawb ntawm qhov profile. Tus Tsov tus tw kawg yog stacked aluminium matrix. Thaum muaj ntau ntawm aluminium daig nyob rau hauv nruab nrab ntawm txoj siv sia (cov ntawv cog lus muaj zog), nws yuav ua rau muaj qhov khawb khawb.

(6) Lub extrusion ceev muaj kev cuam tshuam zoo rau kev rub. Kev cuam tshuam ntawm extrusion ceev. Raws li qhov kev soj ntsuam ntawm 6005 alloy muaj kev txhawj xeeb, qhov extrusion ceev nce nyob rau hauv qhov kev sim ntau, qhov hluav taws xob kub nce, thiab cov xov tooj ntawm cov khoom rub tawm tau nce thiab hnyav dua li cov kab ntau lawm. Lub extrusion ceev yuav tsum tau khaws cia kom ruaj khov li sai tau kom tsis txhob muaj kev hloov pauv sai. Kev ceev extrusion ntau dhau thiab qhov hluav taws xob kub siab yuav ua rau muaj kev sib txhuam ntxiv thiab rub cov khoom loj. Cov txheej txheem tshwj xeeb ntawm kev cuam tshuam ntawm extrusion ceev ntawm qhov rub tawm tshwm sim yuav tsum tau ua raws li kev soj ntsuam thiab kev txheeb xyuas.

(7) Qhov zoo ntawm cov cam khwb cia pas nrig kuj yog ib qho tseem ceeb cuam tshuam rau cov khoom rub tawm. Qhov saum npoo ntawm cov cam khwb cia yog ntxhib, nrog sawing burrs, roj stains, plua plav, corrosion, thiab lwm yam, tag nrho cov uas ua rau muaj kev nyiam ntawm rub tawm.

4 Kev xaus

(1) Qhov sib xyaw ntawm rub tawm qhov tsis xws luag yog raws li cov matrix; Qhov muaj pes tsawg leeg ntawm txoj hauj lwm particle yog pom tseeb txawv ntawm cov matrix, feem ntau muaj O, C, Fe, thiab Si ntsiab.

(2) Pulling particle defects feem ntau yog tshwm sim los ntawm aluminium sticking rau pwm ua hauj lwm txoj siv. Txhua yam uas txhawb nqa txhuas ua rau cov pwm ua haujlwm yuav ua rau rub tsis xws luag. Nyob rau ntawm qhov chaw ua kom ntseeg tau qhov zoo ntawm cov cam khwb cia, lub cim ntawm rub cov khoom tsis muaj kev cuam tshuam ncaj qha rau cov hlau alloy.

(3) Kev kho hluav taws zoo li qub yog qhov zoo los txo qhov rub tawm.

Post lub sij hawm: Sep-10-2024