Part.1 rational design

Cov pwm yog tsim los raws li cov kev xav tau ntawm kev siv, thiab nws cov qauv qee zaum tsis tuaj yeem tsim nyog thiab sib npaug sib npaug. Qhov no xav kom tus tsim qauv siv qee qhov kev ntsuas zoo thaum tsim pwm yam tsis muaj kev cuam tshuam rau kev ua haujlwm ntawm pwm, thiab sim ua tib zoo saib xyuas cov txheej txheem tsim khoom, kev tsim nyog ntawm cov qauv thiab qhov sib luag ntawm cov duab geometric.

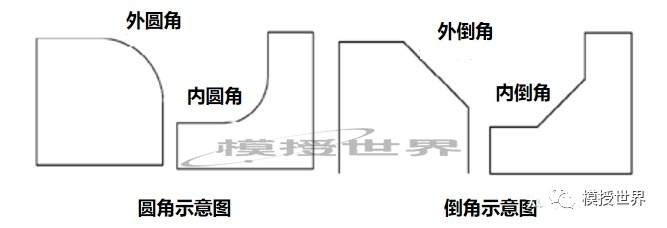

(1) Sim zam cov ces kaum ntse thiab ntu nrog qhov sib txawv loj hauv thickness

Yuav tsum muaj kev hloov pauv ntawm kev sib tshuam ntawm cov ntu tuab thiab nyias ntawm cov pwm. Qhov no tuaj yeem txo qhov kub ntawm qhov sib txawv ntawm qhov sib txawv ntawm cov pwm, txo cov thermal kev nyuab siab, thiab tib lub sij hawm txo qhov tsis sib xws ntawm cov ntaub so ntswg hloov pauv ntawm ntu ntu, thiab txo qhov kev ntxhov siab ntawm cov ntaub so ntswg. Daim duab 1 qhia tau hais tias cov pwm txais kev hloov pauv thiab hloov lub khob hliav qab.

(2) Tsim nyog nce cov txheej txheem qhov

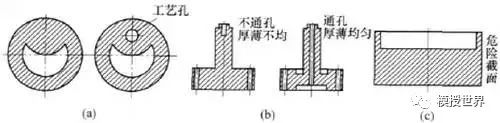

Rau qee cov pwm uas tsis tuaj yeem lav qhov kev sib txuam thiab sib luag, nws yog ib qho tsim nyog los hloov qhov tsis yog los ntawm lub qhov rau hauv ib qho los ntawm lub qhov los yog ua rau qee qhov txheej txheem qhov tsim nyog yam tsis muaj kev cuam tshuam rau kev ua haujlwm.

Daim duab 2a qhia txog qhov tuag nrog lub qhov nqaim, uas yuav raug deformed raws li qhia los ntawm kab dotted tom qab quenching. Yog tias ob txheej txheej txheem tuaj yeem ntxiv rau hauv qhov tsim (raws li pom hauv daim duab 2b), qhov sib txawv ntawm qhov sib txawv ntawm qhov sib txawv thaum lub sij hawm quenching txheej txheem yog txo, thermal stress yog txo, thiab deformation yog ho txhim kho.

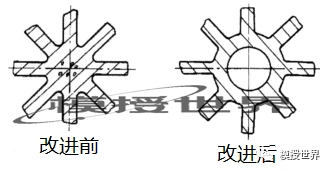

(3) Siv cov qauv kaw thiab sib xyaw kom ntau li ntau tau

Thaum cov pwm qhib los yog asymmetrical, qhov kev ntxhov siab faib tom qab quenching tsis sib xws thiab nws yooj yim rau deform. Yog li ntawd, rau cov pwm deformable trough pwm, qhov cuab lub zog yuav tsum tau ua ua ntej quenching, thiab ces txiav tawm tom qab quenching. Lub trough workpiece qhia nyob rau hauv daim duab 3 yog Ameslikas deformed ntawm R tom qab quenching, thiab ntxiv dag zog (qhov hatched ib feem nyob rau hauv daim duab 3), tuaj yeem tiv thaiv quenching deformation.

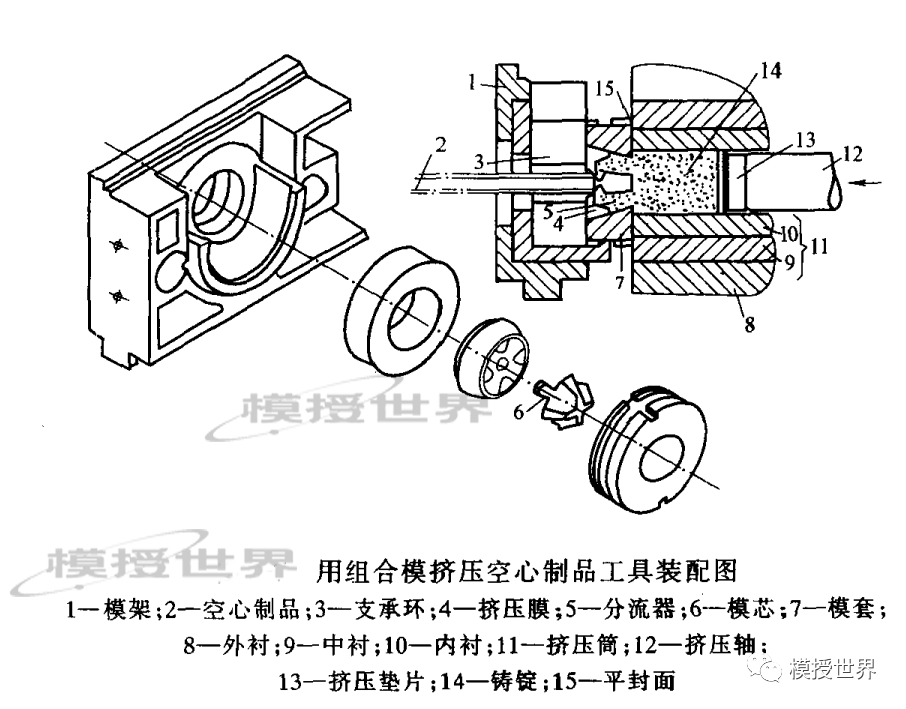

(4) Txais cov qauv sib xyaw ua ke, uas yog, ua kom muaj kev sib txawv pwm, cais cov pwm sab saud thiab sab qis ntawm cov pwm sib txawv, thiab cais cov tuag thiab xuas nrig.

Rau cov tuag loj nrog cov duab thiab qhov loj> 400mm thiab xuas nrig ntaus nrog cov tuab me me thiab ntev ntev, nws yog qhov zoo tshaj plaws los siv cov qauv sib xyaw ua ke, ua kom yooj yim, txo qhov loj rau me me, thiab hloov cov pwm sab hauv mus rau sab nrauv, uas tsis yog tsuas yog yooj yim rau cua sov thiab ua kom txias.

Thaum tsim cov qauv sib xyaw ua ke, feem ntau nws yuav tsum tau decomposed raws li cov hauv qab no yam tsis muaj kev cuam tshuam qhov haum qhov tseeb:

- Kho lub thickness thiaj li hais tias tus ntoo khaub lig-section ntawm pwm nrog sib txawv heev cross-sections yeej ib txwm zoo tom qab decomposition.

- Decompose nyob rau hauv qhov chaw uas muaj kev ntxhov siab yog ib qho yooj yim los tsim, disperse nws txoj kev ntxhov siab, thiab tiv thaiv cracking.

- Koom tes nrog cov txheej txheem qhov ua kom cov qauv symmetrical.

- Nws yog qhov yooj yim rau kev ua haujlwm txias thiab kub thiab yooj yim rau kev sib sau.

- Qhov tseem ceeb tshaj plaws yog kom ntseeg tau tias siv tau.

Raws li pom nyob rau hauv daim duab 4, nws yog ib tug loj tuag. Yog tias cov qauv tsim tau txais, tsis yog tsuas yog kev kho cua sov yuav nyuaj, tab sis kuj cov kab noj hniav yuav poob qis tom qab quenching, thiab txawm tias ua rau tsis sib xws thiab dav hlau distortion ntawm ntug txiav, uas yuav nyuaj rau kev kho hauv kev ua haujlwm tom ntej. , yog li ntawd, kev sib koom ua ke tuaj yeem txais yuav. Raws li cov kab dotted hauv daim duab 4, nws muab faib ua plaub ntu, thiab tom qab kev kho cua sov, lawv tau sib sau ua ke thiab tsim, thiab tom qab ntawd hauv av thiab sib xyaw. Qhov no tsis tsuas yog ua kom yooj yim rau kev kho cua sov, tab sis kuj daws qhov teeb meem ntawm deformation.

Part.2 raug xaiv cov khoom

Thaum tshav kub kub kho deformation thiab cracking yog ze ze rau cov hlau siv thiab nws zoo, yog li nws yuav tsum tau raws li qhov yuav tsum tau ua ntawm cov pwm. Tsim nyog xaiv cov hlau yuav tsum coj mus rau hauv tus account qhov precision, qauv thiab qhov loj ntawm cov pwm, nrog rau cov xwm, kom muaj nuj nqis thiab cov txheej txheem ntawm cov khoom tiav. Yog tias cov pwm dav dav tsis muaj deformation thiab precision yuav tsum tau, cov cuab yeej carbon steel yuav siv tau raws li tus nqi txo; kom yooj yim deformed thiab tawg qhov chaw, alloy cuab yeej steel nrog lub zog siab dua thiab qeeb qeeb quenching thiab txias ceev yuav siv tau; Piv txwv li, cov khoom siv hluav taws xob tuag thaum chiv thawj siv T10A steel, loj deformation thiab yooj yim tawg tom qab dej quenching thiab roj txias, thiab alkali da dej quenching kab noj hniav tsis yooj yim rau harden. Tam sim no siv 9Mn2V steel lossis CrWMn steel, quenching hardness thiab deformation tuaj yeem ua tau raws li qhov yuav tsum tau ua.

Nws tuaj yeem pom tias thaum lub pwm deformation ua los ntawm cov hlau tsis tau raws li qhov yuav tsum tau ua, nws tseem raug nqi siv cov hlau alloy xws li 9Mn2V steel lossis CrWMn steel. Txawm hais tias tus nqi ntawm cov khoom siv me ntsis siab dua, qhov teeb meem ntawm deformation thiab tawg yog daws.

Thaum xaiv cov ntaub ntawv kom raug, nws tseem yuav tsum tau ua kom muaj kev soj ntsuam thiab tswj cov khoom siv raw kom tsis txhob muaj pwm kub kho tawg vim cov khoom siv raw khoom tsis raug.

Kho los ntawm May Jiang los ntawm MAT Aluminium

Post lub sij hawm: Sep-16-2023