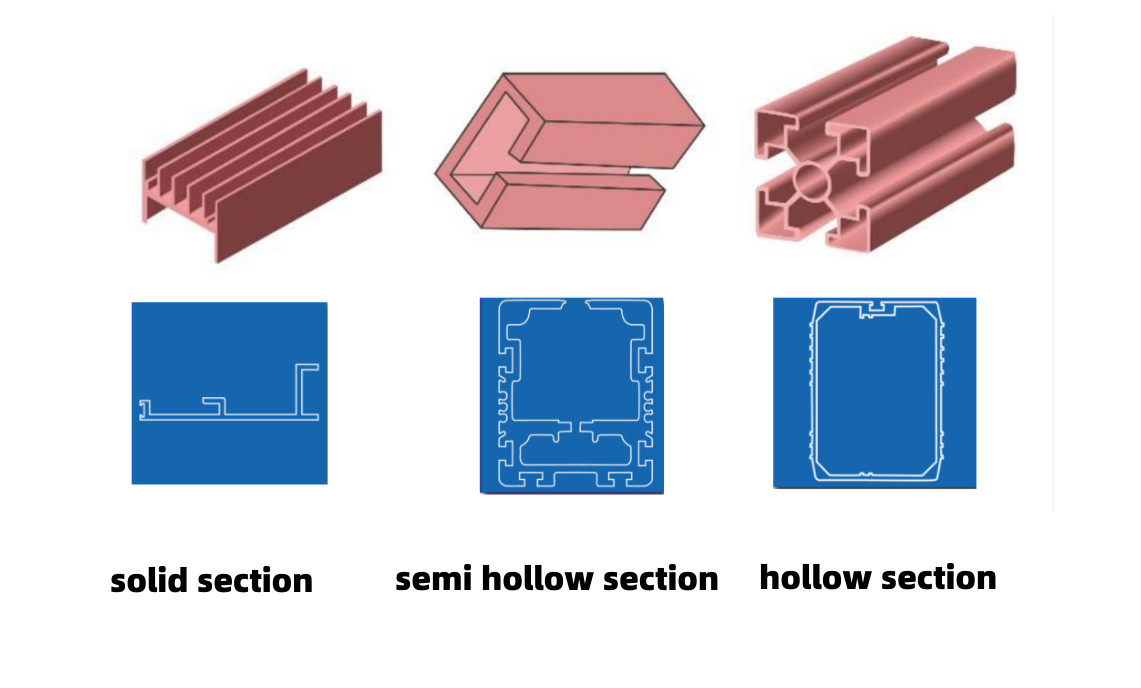

Ntu ntawm aluminium extrusion yog muab faib ua peb pawg:

Khoom seem: tus nqi khoom qis, tus nqi pwm qis

Semi hollow seem: cov pwm yog ib qho yooj yim rau hnav thiab tsim kua muag thiab tawg, nrog cov khoom lag luam siab thiab cov nqi pwm

Hollow seem: cov khoom lag luam siab thiab cov nqi pwm, tus nqi pwm siab tshaj plaws rau cov khoom ntxeem tau

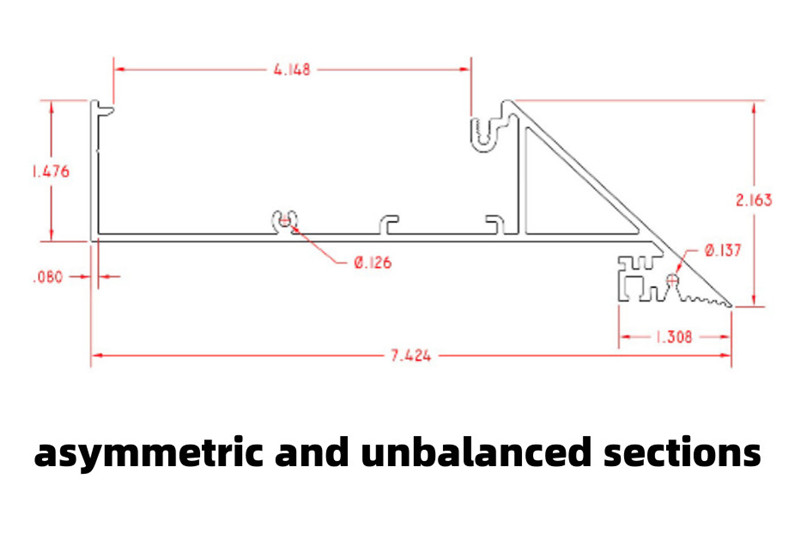

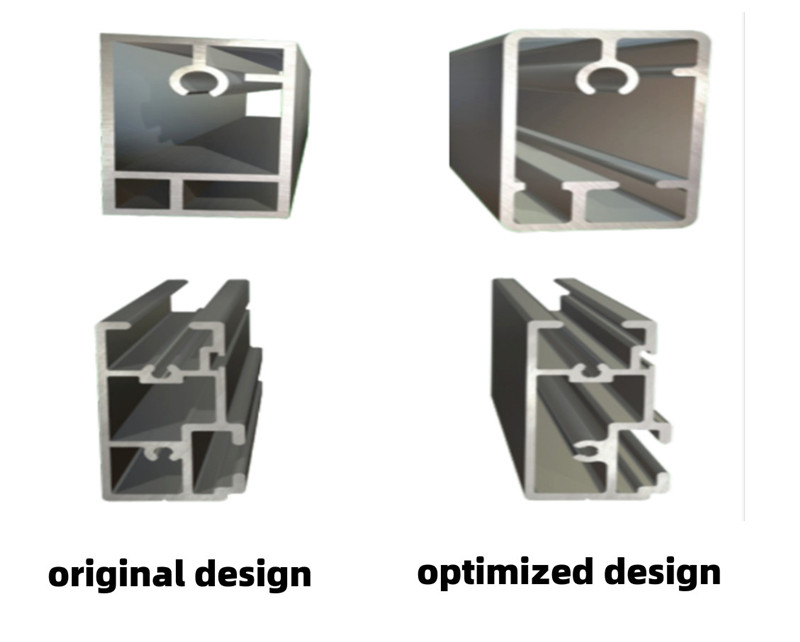

1.Txhob cov seem asymmetrical thiab tsis sib npaug

Cov seem asymmetric thiab tsis sib npaug nce qhov nyuaj ntawm extrusion, thiab tib lub sijhawm, cov teeb meem zoo yuav tshwm sim, zoo li qhov tseeb qhov tseeb thiab flatness yog ib qho nyuaj los xyuas kom meej, lub bowing thiab twisting ntawm qhov chaw, tsis tshua muaj ntau lawm efficiency, thiab pwm yog ib qho yooj yim mus hnav thiab tsim kua muag thaum lub sij hawm ntau lawm.

Qhov ntau asymmetric lossis tsis sib npaug ntawm ntu ntawm aluminium extrusion, qhov nyuaj dua nws yog los xyuas kom meej qhov ncaj, lub kaum sab xis thiab lwm qhov raug.

Txawm hais tias cov duab asymmetrical thiab tsis sib npaug tuaj yeem tsim tau, cov hlau tsis tshua muaj peev xwm ntws mus rau hauv qhov nqaim thiab tsis xwm yeem thaum lub sij hawm extrusion, qhov twg distortion lossis lwm yam teeb meem zoo tuaj yeem tshwm sim tau yooj yim.

Tsis tas li ntawd, txawm tias nws muaj peev xwm extrude asymmetric thiab cov duab tsis sib npaug, cov cuab yeej siv ntau dua thiab cov nqi tsim khoom ntau dua vim qeeb extrusion speeds, nws thiaj li ua rau cov pwm ua cov nqi ntau dua thiab cov nqi tsim khoom.

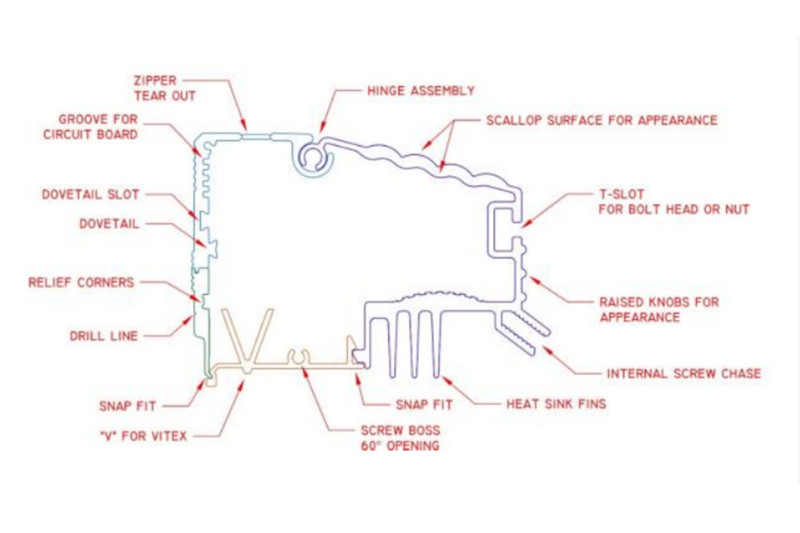

Qhov ntau dua tus naj npawb ntawm sab thiab cov channel hauv ib qho extrusion profile, qhov tsawg dua thiab kim dua nws yuav yog.

2.Qhov yooj yim ntawm cov duab seem, qhov zoo dua

Qee cov khoom tsim engineers tsim ntau yam nta hauv aluminium extrusion. Txawm hais tias qhov tshwj xeeb zoo ntawm aluminium extrusion yog ntxiv qhov, qhov los yog cov ntsia hlau tus thawj coj hauv ntu, nws yuav ua rau cov pwm tsim nyuaj heev, lossis tsis tuaj yeem extrudable tag nrho nrog cov nqi tsim khoom kim heev.

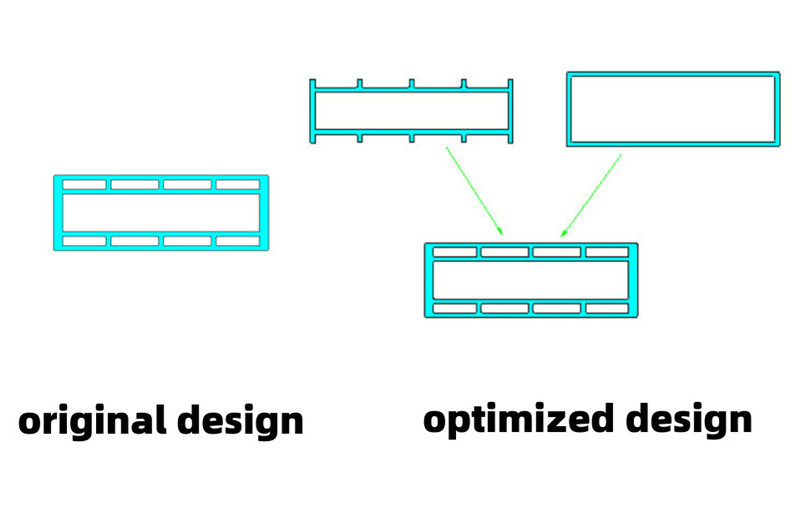

Thaum cov seem ntawm extrusion yog nyuaj heev, nws tuaj yeem txiav txim siab siv ob lossis ntau qhov chaw rau extrusion.

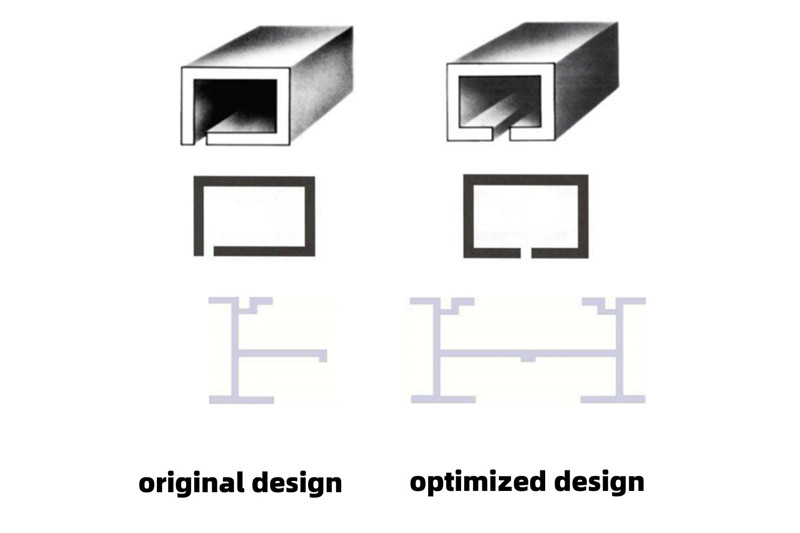

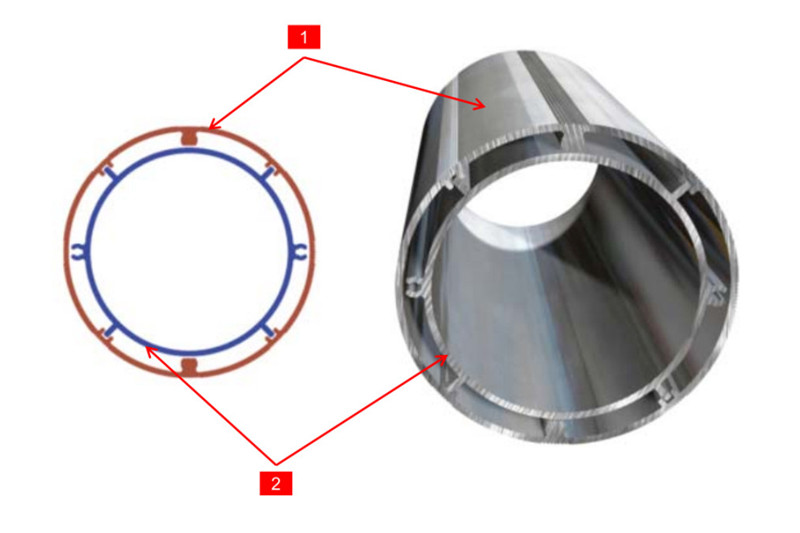

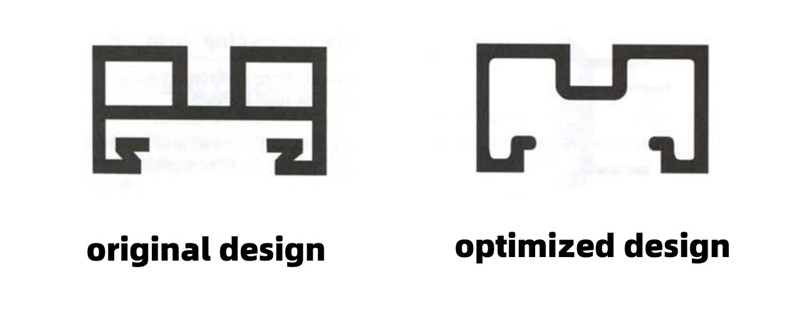

3.Porous hollow seem optimized rau ib leeg-qhov hollow seem

Los ntawm optimizing qhov ntxeem tau ntawm hollow seem rau hauv ib lub qhov hollow seem, cov qauv pwm tuaj yeem ua kom yooj yim thiab tus nqi yuav txuag tau.

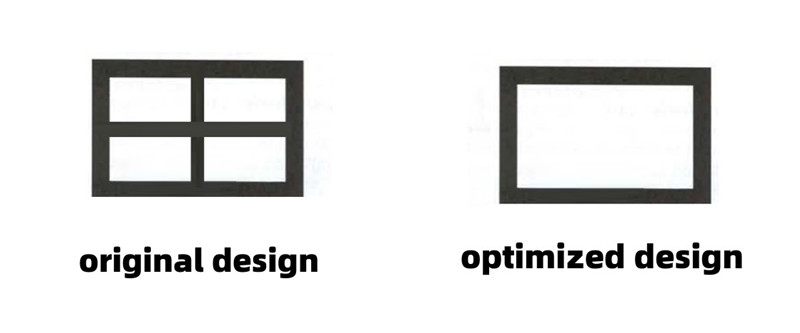

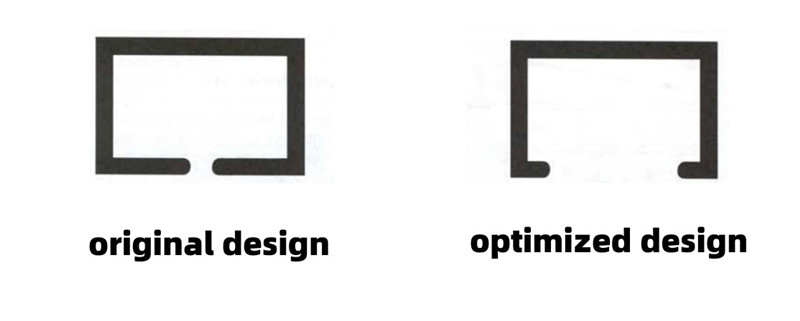

4.Hollow seem optimized rau semi-hollow seem

Los ntawm optimizing lub hollow seem mus rau ib tug semi-hollow seem, cov pwm qauv yuav ua tau yooj yim thiab tus nqi yuav txuag tau.

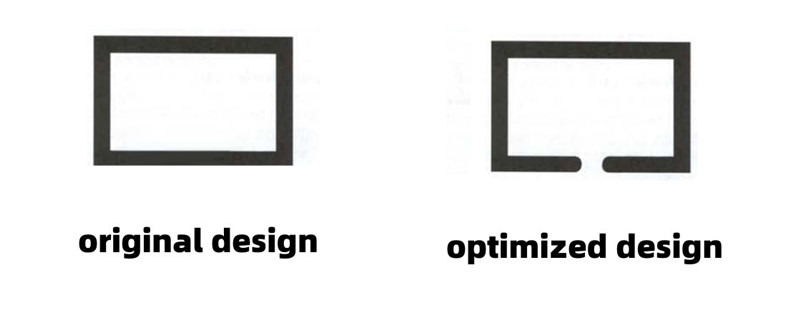

5.Semi-hollow seem optimized rau cov khoom seem

Los ntawm optimizing lub semi-hollow seem mus rau ib qho khoom seem, cov qauv pwm tuaj yeem ua kom yooj yim thiab tus nqi yuav txuag tau.

6.Txhob qhov ntxeem tau

Cov ntu ntxeem tau tuaj yeem ua kom zoo dua los ntawm kev tsim los txo cov nqi pwm thiab nyuaj rau kev ua thiab ntau lawm.

Kho los ntawm May Jiang los ntawm MAT Aluminium

Peb Hlis 16, 2023

Post lub sij hawm: Feb-18-2023