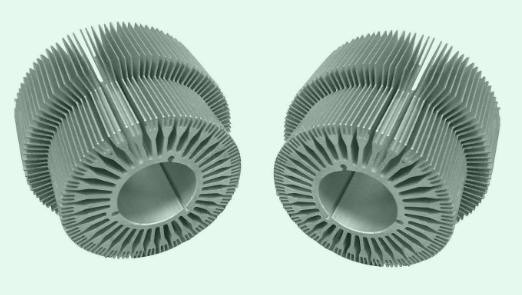

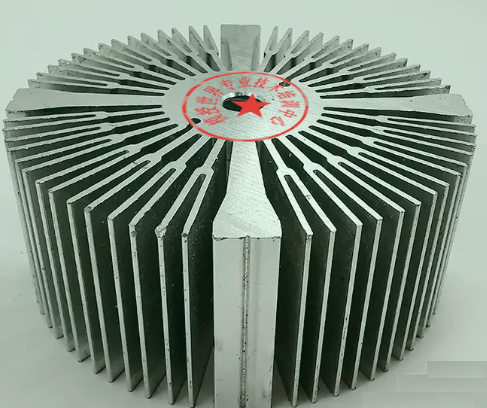

Vim tias aluminium alloys yog lub teeb yuag, zoo nkauj, muaj kev tiv thaiv corrosion zoo, thiab muaj cov thermal conductivity thiab kev ua haujlwm zoo, lawv tau siv dav hauv cov khoom siv hluav taws xob hauv IT kev lag luam, hluav taws xob thiab kev lag luam tsheb, tshwj xeeb tshaj yog nyob rau hauv kev lag luam LED tam sim no. Cov aluminium alloy cua sov dissipation Cheebtsam no muaj cov cua sov ua haujlwm zoo. Hauv kev tsim khoom, tus yuam sij kom ua tau zoo extrusion ntau lawm ntawm cov radiator profiles yog cov pwm. Vim tias cov profiles no feem ntau muaj cov yam ntxwv ntawm cov qauv loj thiab cov kev tuag ntawm cov qauv sib tsoo tsis tuaj yeem ua tau zoo ntawm cov duab muaj zog thiab cov tshuaj pwm sib xyaw.

Tam sim no, cov lag luam vam khom ntau dua rau qhov zoo ntawm cov pwm hlau. Txhawm rau txhim kho lub zog ntawm cov pwm, lawv tsis yig los siv cov khoom siv kim kim. Tus nqi ntawm cov pwm yog siab heev, thiab qhov tseeb nruab nrab lub neej ntawm cov pwm yog tsawg dua 3t, uas ua rau lub lag luam tus nqi ntawm lub radiator yog tus nqi siab, nruj txwv tsis pub nce qib thiab nrov ntawm LED teeb. Yog li ntawd, extrusion tuag rau sunflower-shaped radiator profiles tau nyiam heev los ntawm engineering thiab cov neeg ua haujlwm hauv kev lag luam.

Kab lus no qhia txog ntau yam thev naus laus zis ntawm sunflower radiator profile extrusion tuag tau los ntawm kev tshawb fawb ntau xyoo thiab rov sim ntau lawm los ntawm cov piv txwv hauv kev tsim khoom tiag tiag, rau kev siv los ntawm cov phooj ywg.

1. Kev txheeb xyuas cov yam ntxwv ntawm cov khoom siv txhuas profile

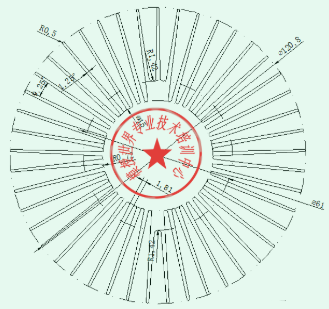

Daim duab 1 qhia txog ntu ntu ntawm cov paj noob hlis radiator txhuas profile. Qhov chaw hla ntu ntawm qhov profile yog 7773.5mm², nrog rau tag nrho ntawm 40 cov hniav kub dissipation. Qhov siab tshaj plaws dai qhib loj tsim ntawm cov hniav yog 4.46 hli. Tom qab xam, tus nplaig piv ntawm cov hniav yog 15.7. Nyob rau tib lub sijhawm, muaj thaj tsam loj hauv qhov chaw ntawm qhov profile, nrog thaj tsam ntawm 3846.5mm².

Kev txiav txim siab los ntawm cov yam ntxwv ntawm qhov profile, qhov chaw nruab nrab ntawm cov hniav tuaj yeem suav tau tias yog ib nrab hollow profiles, thiab radiator profile yog tsim los ntawm ntau yam semi-hollow profiles. Yog li ntawd, thaum tsim pwm qauv, tus yuam sij yog xav txog yuav ua li cas los xyuas kom meej lub zog ntawm pwm. Txawm hais tias rau semi-hollow profiles, kev lag luam tau tsim ntau yam mature qauv, xws li "pob splitter pwm", "txiav splitter pwm", "txheej txheem choj splitter pwm", thiab lwm yam. Txawm li cas los xij, cov qauv no tsis siv rau cov khoom tsim los ntawm ntau yam semi-hollow profiles. Kev tsim qauv tsuas yog txiav txim siab cov ntaub ntawv, tab sis nyob rau hauv extrusion molding, qhov loj tshaj qhov cuam tshuam ntawm lub zog yog extrusion quab yuam thaum lub sij hawm extrusion txheej txheem, thiab cov txheej txheem hlau yog lub ntsiab tseem ceeb tsim extrusion quab yuam.

Vim yog qhov loj hauv nruab nrab ntawm lub hnub ci hluav taws xob profile, nws yooj yim heev los ua kom tag nrho cov dej ntws hauv cheeb tsam no ceev heev thaum lub sij hawm extrusion txheej txheem, thiab ntxiv tensile kev nyuaj siab yuav raug generated nyob rau hauv lub taub hau ntawm lub intertooth ncua kev kawm ntawv raj, uas ua rau lub puas ntawm lub intertooth ncua kev kawm ntawv raj. Yog li ntawd, hauv kev tsim cov qauv pwm, peb yuav tsum tsom mus rau kev hloov pauv ntawm cov hlau ntws thiab cov nqi ntws kom ua tiav lub hom phiaj ntawm kev txo extrusion siab thiab txhim kho lub xeev kev ntxhov siab ntawm cov yeeb nkab ntawm cov hniav, txhawm rau txhim kho lub zog ntawm cov pwm.

2. Kev xaiv pwm qauv thiab extrusion xovxwm muaj peev xwm

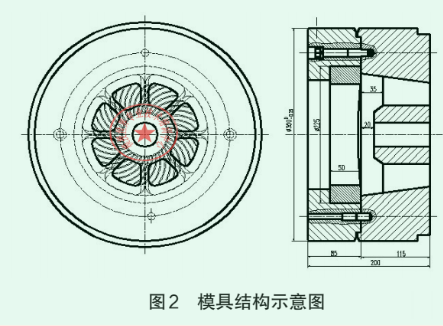

2.1 Pwm qauv daim ntawv

Rau cov paj noob hlis radiator profile qhia hauv daim duab 1, txawm hais tias nws tsis muaj qhov hollow, nws yuav tsum tau txais cov qauv pwm cais raws li qhia hauv daim duab 2. Qhov txawv ntawm cov qauv shunt pwm, cov hlau soldering chaw nres tsheb chamber tau muab tso rau hauv cov pwm sab saud, thiab cov qauv ntxig yog siv rau hauv cov pwm qis. Lub hom phiaj yog los txo cov nqi pwm thiab txo lub voj voog tsim pwm. Ob lub pwm sab sauv thiab sab pwm pwm yog universal thiab tuaj yeem rov siv dua. Qhov tseem ceeb tshaj, qhov tuag qhov blocks tuaj yeem ua tiav ntawm nws tus kheej, uas tuaj yeem ua kom zoo dua qhov tseeb ntawm qhov tuag qhov siv txoj siv sia. Lub puab qhov ntawm cov pwm qis yog tsim los ua ib kauj ruam. Lub sab sauv thiab cov pwm qhov thaiv tau txais kev pom zoo, thiab qhov sib txawv ntawm ob sab yog 0.06 ~ 0.1m; Qhov qis dua txais kev cuam tshuam haum, thiab qhov cuam tshuam ntawm ob sab yog 0.02 ~ 0.04m, uas yuav pab kom muaj kev sib koom ua ke thiab txhawb kev sib koom ua ke, ua rau cov inlay haum ntau dua, thiab tib lub sijhawm, nws tuaj yeem zam pwm deformation los ntawm thermal installation cuam tshuam haum.

2.2 Xaiv lub peev xwm extruder

Kev xaiv ntawm lub peev xwm extruder yog, ntawm ib sab, los txiav txim siab qhov tsim nyog sab hauv txoj kab uas hla ntawm lub extrusion chim thiab qhov siab tshaj plaws tshwj xeeb ntawm lub extruder ntawm lub extrusion chim seem kom tau raws li lub siab thaum lub sij hawm tsim hlau. Ntawm qhov tod tes, nws yog los txiav txim qhov tsim nyog extrusion piv thiab xaiv qhov tsim nyog pwm loj specifications raws li tus nqi. Rau sunflower radiator aluminium profile, qhov sib piv extrusion tsis tuaj yeem loj dhau. Lub ntsiab yog vim li cas yog hais tias lub extrusion quab yuam yog proportional rau lub extrusion ratio. Qhov ntau dua qhov sib piv extrusion, qhov ntau dua lub zog extrusion. Qhov no yog qhov tsis zoo rau cov paj noob hlis radiator aluminium profile pwm.

Kev paub qhia tau hais tias tus extrusion ratio ntawm txhuas profiles rau sunflower radiators yog tsawg tshaj li 25. Rau cov profile qhia nyob rau hauv daim duab 1, ib tug 20.0 MN extruder nrog ib tug extrusion chim puab txoj kab uas hla ntawm 208 mm. Tom qab kev suav, qhov siab tshaj plaws tshwj xeeb ntawm extruder yog 589MPa, uas yog tus nqi tsim nyog dua. Yog tias qhov tshwj xeeb siab dhau lawm, lub siab ntawm cov pwm yuav loj, uas yog kev puas tsuaj rau lub neej ntawm pwm; Yog tias qhov tshwj xeeb siab qis dhau lawm, nws tsis tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm extrusion txoj kev. Kev paub qhia tau hais tias lub siab tshwj xeeb hauv thaj tsam ntawm 550 ~ 750 MPa tuaj yeem ua tau raws li ntau yam kev xav tau. Tom qab muab xam, lub extrusion coefficient yog 4.37. Cov pwm loj specification yog xaiv li 350 mmx200 mm (sab nraud txoj kab uas hla x degrees).

3. Kev txiav txim siab ntawm pwm cov qauv tsis

3.1 Upper pwm structural tsis

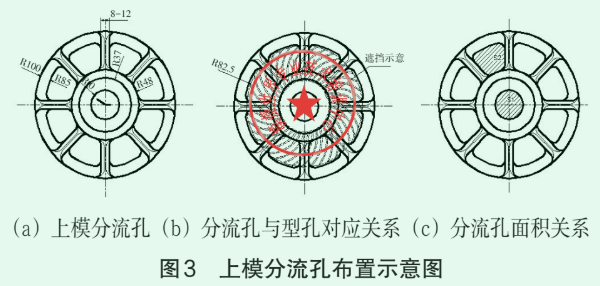

(1) Tus naj npawb thiab kev npaj ntawm diverter qhov. Rau sunflower radiator profile shunt pwm, ntau tus naj npawb ntawm shunt qhov, qhov zoo dua. Rau cov profiles nrog cov duab zoo sib xws, 3 mus rau 4 tsoos shunt qhov feem ntau xaiv. Qhov tshwm sim yog tias qhov dav ntawm tus choj shunt loj dua. Feem ntau, thaum nws loj dua 20 hli, cov welds tsawg dua. Txawm li cas los xij, thaum xaiv txoj siv sia ua haujlwm ntawm lub qhov tuag, txoj siv sia ua haujlwm ntawm lub qhov tuag nyob hauv qab ntawm tus choj shunt yuav tsum luv dua. Nyob rau hauv cov xwm txheej uas tsis muaj kev suav meej meej rau kev xaiv ntawm txoj siv sia ua haujlwm, nws yuav ua rau lub qhov tuag hauv qab tus choj thiab lwm qhov chaw tsis tuaj yeem ua tiav raws nraim tib yam kev khiav dej num thaum lub sij hawm extrusion vim qhov sib txawv ntawm txoj siv sia ua haujlwm, qhov sib txawv ntawm qhov ntws yuav ua rau muaj zog tensile ntxiv ntawm lub cantilever thiab ua rau deflection ntawm cov hniav kub dissipation. Yog li ntawd, rau sunflower radiator extrusion tuag nrog ib tug tuab ntawm cov hniav, nws yog ib qho tseem ceeb heev kom paub meej tias qhov txaus tus nqi ntawm txhua tus hniav zoo ib yam. Raws li tus naj npawb ntawm shunt qhov nce, tus naj npawb ntawm shunt txuas ntxiv yuav nce raws li, thiab tus nqi ntws thiab ntws faib ntawm cov hlau yuav ua ntau dua. Qhov no yog vim hais tias raws li tus naj npawb ntawm shunt txuas ntxiv, qhov dav ntawm shunt txuas hniav tuaj yeem raug txo raws li.

Cov ntaub ntawv qhia tau hais tias tus naj npawb ntawm shunt qhov feem ntau yog 6 lossis 8, lossis ntau dua. Tau kawg, rau qee qhov loj paj paj tawg paj tawg paj, cov pwm sab saud tuaj yeem npaj lub qhov shunt raws li lub hauv paus ntsiab lus ntawm shunt choj dav ≤ 14mm. Qhov txawv yog tias lub phaj pem hauv ntej yuav tsum tau muab ntxiv rau kev faib ua ntej thiab kho cov hlau ntws. Tus naj npawb thiab kev npaj ntawm qhov diverter qhov nyob rau hauv pem hauv ntej diverter phaj tuaj yeem ua tau raws li ib txwm muaj.

Tsis tas li ntawd, thaum npaj lub qhov shunt, kev txiav txim siab yuav tsum tau muab rau kev siv cov pwm sab sauv kom tsim nyog tiv thaiv lub taub hau ntawm cantilever ntawm cov hniav kub kom tiv thaiv cov hlau los ntawm ncaj qha mus tsoo lub taub hau ntawm cantilever raj thiab yog li txhim kho cov kev ntxhov siab ntawm lub cantilever raj. Qhov thaiv ntawm lub taub hau cantilever ntawm cov hniav tuaj yeem yog 1/5 ~ 1/4 ntawm qhov ntev ntawm lub cantilever raj. Qhov layout ntawm shunt qhov yog qhia hauv daim duab 3

(2) Qhov kev sib raug zoo ntawm lub qhov shunt. Vim tias cov phab ntsa tuab ntawm cov hauv paus hniav ntawm cov hniav kub yog me me thiab qhov siab nyob deb ntawm qhov chaw, thiab qhov chaw ntawm lub cev yog qhov sib txawv ntawm qhov chaw, nws yog qhov nyuaj tshaj plaws los ua cov hlau. Yog li ntawd, lub ntsiab lus tseem ceeb hauv kev tsim cov paj noob hlis radiator profile pwm yog ua kom tus nqi ntws ntawm cov khoom hauv nruab nrab kom qeeb li sai tau kom ntseeg tau tias cov hlau ua ntej sau cov hauv paus hniav. Txhawm rau ua tiav cov txiaj ntsig zoo li no, ntawm ib sab, nws yog qhov kev xaiv ntawm txoj siv sia ua haujlwm, thiab qhov tseem ceeb tshaj plaws, kev txiav txim siab ntawm thaj tsam ntawm lub qhov diverter, feem ntau yog thaj tsam ntawm qhov nruab nrab ntawm qhov sib thooj rau lub qhov diverter. Kev ntsuam xyuas thiab cov txiaj ntsig pom tau pom tias qhov txiaj ntsig zoo tshaj plaws yog ua tiav thaum thaj tsam ntawm lub hauv paus diverter qhov S1 thiab thaj tsam ntawm sab nraud ib leeg diverter qhov S2 txaus siab rau cov kev sib raug zoo hauv qab no: S1 = (0.52 ~ 0.72) S2

Tsis tas li ntawd, qhov zoo hlau ntws channel ntawm lub hauv paus splitter qhov yuav tsum yog 20 ~ 25mm ntev tshaj li qhov zoo hlau ntws channel ntawm lub qhov splitter txheej. Qhov ntev no kuj yuav siv sij hawm rau hauv tus account cov npoo thiab muaj peev xwm kho pwm.

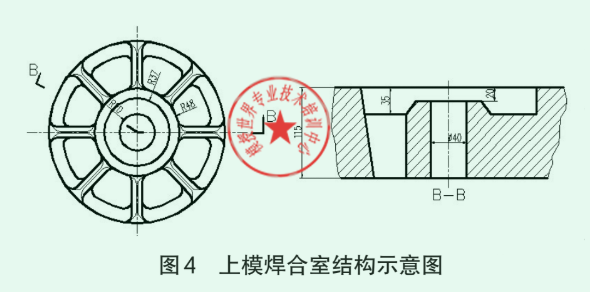

(3) Qhov tob ntawm lub vuam chamber. Sunflower radiator profile extrusion tuag yog txawv ntawm cov tsoos shunt tuag. Nws tag nrho cov vuam chamber yuav tsum nyob rau hauv lub Upper tuag. Qhov no yog los xyuas kom meej qhov tseeb ntawm lub qhov thaiv kev ua haujlwm ntawm qhov qis tuag, tshwj xeeb tshaj yog qhov tseeb ntawm txoj siv sia ua haujlwm. Piv nrog rau cov tsoos shunt pwm, qhov tob ntawm vuam chamber ntawm Sunflower radiator profile shunt pwm yuav tsum tau nce. Qhov ntau dua lub tshuab extrusion muaj peev xwm, qhov ntau dua qhov nce hauv qhov tob ntawm lub vuam chamber, uas yog 15 ~ 25mm. Piv txwv li, yog siv 20 MN extrusion tshuab, qhov tob ntawm vuam chamber ntawm cov tsoos shunt tuag yog 20 ~ 22 hli, thaum lub qhov tob ntawm lub vuam chamber ntawm shunt tuag ntawm sunflower radiator profile yuav tsum yog 35 ~ 40 hli. Qhov kom zoo dua ntawm qhov no yog tias cov hlau yog welded tag nrho thiab kev ntxhov siab ntawm cov yeeb nkab uas raug tshem tawm tau txo qis heev. Cov qauv ntawm lub puab pwm vuam chamber yog qhia nyob rau hauv daim duab 4.

3.2 Tsim qhov tuag qhov ntxig

Kev tsim ntawm qhov tuag qhov thaiv feem ntau suav nrog qhov tuag qhov loj, siv txoj siv sia, sab nraud thiab thickness ntawm daim iav thaiv, thiab lwm yam.

(1) Kev txiav txim siab ntawm qhov tuag qhov loj. Qhov luaj li cas ntawm qhov tuag tuaj yeem txiav txim siab nyob rau hauv ib txoj kev ib txwm muaj, feem ntau yog xav txog qhov ntsuas ntawm cov txheej txheem thermal.

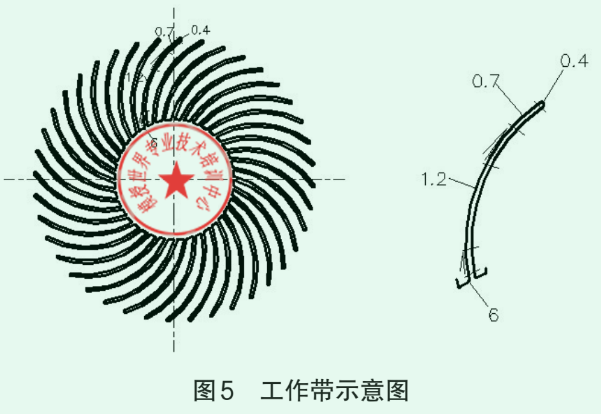

(2) Kev xaiv txoj siv sia ua haujlwm. Lub hauv paus ntsiab lus ntawm kev xaiv txoj hlua khi ua haujlwm yog ua ntej kom ntseeg tau tias cov khoom siv ntawm tag nrho cov hlau nyob hauv qab ntawm cov hniav hauv paus yog txaus, yog li ntawd cov ndlwg ntawm cov hauv paus hniav yog sai dua lwm yam. Yog li ntawd, txoj siv sia ua haujlwm nyob rau hauv qab ntawm cov hauv paus hniav yuav tsum yog luv tshaj plaws, nrog rau tus nqi ntawm 0.3 ~ 0.6 hli, thiab txoj siv sia ua haujlwm ntawm qhov chaw nyob ib sab yuav tsum tau nce 0.3 hli. Lub hauv paus ntsiab lus yog nce los ntawm 0.4 ~ 0.5 txhua 10 ~ 15mm mus rau qhov chaw; thib ob, txoj siv sia ua haujlwm ntawm cov khoom loj tshaj plaws ntawm qhov chaw yuav tsum tsis pub tshaj 7 hli. Tsis tas li ntawd, yog tias qhov sib txawv ntawm qhov ntev ntawm txoj siv ua haujlwm loj dhau lawm, qhov yuam kev loj yuav tshwm sim hauv kev ua cov tooj liab electrodes thiab EDM ua haujlwm ntawm txoj siv sia. Qhov yuam kev no tuaj yeem yooj yim ua rau cov hniav deflection tawg thaum lub sij hawm extrusion txheej txheem. Txoj siv sia ua haujlwm tau qhia hauv daim duab 5.

(3) Sab nraud txoj kab uas hla thiab thickness ntawm qhov ntxig. Rau cov tsoos shunt pwm, lub thickness ntawm qhov tuag qhov ntxig yog lub thickness ntawm cov pwm qis. Txawm li cas los xij, rau cov paj noob hlis radiator pwm, yog tias qhov ua tau zoo ntawm qhov tuag qhov loj dhau, qhov profile yuav yooj yim sib tsoo nrog cov pwm thaum lub sij hawm extrusion thiab tawm, ua rau cov hniav tsis sib xws, khawb lossis cov hniav sib tsoo. Cov no yuav ua rau cov hniav tawg.

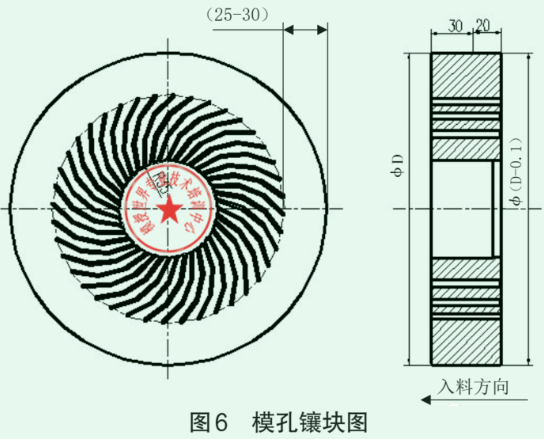

Tsis tas li ntawd, yog tias qhov tuab ntawm qhov tuag ntev dhau lawm, ntawm ib sab, lub sijhawm ua haujlwm ntev ntev thaum lub sijhawm EDM txheej txheem, thiab ntawm qhov tod tes, nws yog ib qho yooj yim ua rau hluav taws xob corrosion sib txawv, thiab nws kuj yog ib qho yooj yim ua rau cov hniav sib txawv thaum lub sij hawm extrusion. Tau kawg, yog tias qhov tuag qhov tuab me dhau, lub zog ntawm cov hniav tsis tuaj yeem lav. Yog li ntawd, noj ob yam no rau hauv kev xav, kev paub qhia tau hais tias qhov tuag qhov ntxig ntawm cov pwm qis feem ntau yog 40 txog 50; thiab sab nraud ntawm lub qhov tuag qhov ntxig yuav tsum yog 25 mus rau 30 hli los ntawm qhov loj tshaj plaws ntawm lub qhov tuag mus rau lub voj voog sab nraud ntawm qhov ntxig.

Rau qhov profile qhia hauv daim duab 1, sab nraud txoj kab uas hla thiab thickness ntawm qhov tuag qhov thaiv yog 225mm thiab 50mm feem. Qhov tuag qhov ntxig yog pom hauv daim duab 6. D hauv daim duab yog qhov loj thiab qhov nominal loj yog 225mm. Qhov txwv qhov sib txawv ntawm nws qhov loj me yog sib npaug raws li lub qhov sab hauv ntawm cov pwm qis kom ntseeg tau tias qhov sib txawv ntawm qhov sib txawv nyob rau hauv qhov ntau ntawm 0.01 ~ 0.02mm. Lub qhov tuag qhov thaiv yog pom nyob rau hauv daim duab 6. Qhov nominal loj ntawm lub puab qhov ntawm lub qhov tuag block muab tso rau hauv lub puab pwm yog 225 hli. Raws li qhov ntsuas qhov tseeb, qhov tuag qhov thaiv yog sib npaug raws li txoj cai ntawm 0.01 ~ 0.02mm ib sab. Lub txheej txoj kab uas hla ntawm qhov tuag qhov thaiv tuaj yeem tau txais raws li D, tab sis rau qhov yooj yim ntawm kev teeb tsa, sab nraud ntawm lub qhov tuag qhov iav thaiv tuaj yeem raug txo kom tsim nyog nyob rau hauv thaj tsam ntawm 0.1m ntawm qhov kawg pub, raws li qhia hauv daim duab.

4. Cov thev naus laus zis tseem ceeb ntawm kev tsim pwm

Lub machining ntawm Sunflower radiator profile pwm tsis txawv ntau ntawm cov txhuas profile pwm. Qhov sib txawv pom tseeb yog feem ntau cuam tshuam hauv kev ua hluav taws xob.

(1) Hais txog kev txiav hlau, nws yog ib qho tsim nyog los tiv thaiv qhov deformation ntawm tooj liab electrode. Vim hais tias cov tooj liab electrode siv rau EDM yog hnyav, cov hniav me me dhau, cov electrode nws tus kheej yog mos, tsis zoo rigidity, thiab lub zos kub kub generated los ntawm hlau txiav ua rau cov electrode tau yooj yim deformed thaum lub sij hawm txiav hlau. Thaum siv cov deformed tooj liab electrodes los ua cov hlua khi ua haujlwm thiab cov riam khoob, cov hniav skewed yuav tshwm sim, uas tuaj yeem yooj yim ua rau cov pwm tawg thaum lub sijhawm ua haujlwm. Yog li ntawd, nws yog ib qho tsim nyog los tiv thaiv qhov deformation ntawm tooj liab electrodes thaum lub sij hawm tsim khoom hauv online. Cov kev tiv thaiv tseem ceeb yog: ua ntej xaim txiav, theem ntawm cov tooj liab thaiv nrog lub txaj; siv lub dial taw qhia los kho qhov verticality thaum pib; thaum txiav hlau, pib los ntawm cov hniav ua ntej, thiab thaum kawg txiav ib feem nrog tuab phab ntsa; Txhua txhua ib zaug, siv cov khoom siv nyiaj hlau los sau cov khoom txiav; Tom qab cov hlau ua tiav, siv lub tshuab xaim los txiav cov ntu luv ntawm li 4 hli raws li qhov ntev ntawm qhov txiav tooj liab electrode.

(2) Hluav taws xob machining yog pom tseeb txawv ntawm cov pwm zoo tib yam. EDM tseem ceeb heev hauv kev ua cov paj noob hlis radiator profile pwm. Txawm hais tias tus qauv tsim zoo tag nrho, qhov tsis xws luag hauv EDM yuav ua rau tag nrho cov pwm yuav tsum tau muab pov tseg. Hluav taws xob tawm machining tsis yog nyob ntawm cov khoom siv xws li xaim txiav. Nws feem ntau nyob ntawm tus neeg teb xov tooj cov kev txawj ua haujlwm thiab kev txawj ntse. Electric discharge machining feem ntau them rau cov nram qab no tsib lub ntsiab lus:

① Hluav taws xob tawm machining tam sim no. 7 ~ 10 Ib qho tam sim no tuaj yeem siv rau thawj zaug EDM machining kom luv lub sijhawm ua haujlwm; 5 ~ 7 Ib qho tam sim no tuaj yeem siv rau kev ua tiav machining. Lub hom phiaj ntawm kev siv me me tam sim no yog kom tau qhov chaw zoo;

② Xyuas kom meej qhov flatness ntawm lub puab kawg lub ntsej muag thiab lub verticality ntawm tooj liab electrode. Tsis zoo flatness ntawm pwm kawg lub ntsej muag los yog tsis txaus verticality ntawm tooj liab electrode ua rau nws nyuaj los xyuas kom meej tias qhov ntev ntawm txoj siv tawv ua hauj lwm tom qab EDM ua raws li qhov tsim txoj siv ntev. Nws yog ib qho yooj yim rau cov txheej txheem EDM ua tsis tau lossis txawm nkag mus rau txoj siv tawv ua haujlwm. Yog li ntawd, ua ntej ua, lub grinder yuav tsum tau siv rau flatten ob kawg ntawm cov pwm kom tau raws li qhov yuav tsum tau, thiab ib tug dial qhia yuav tsum tau siv los kho qhov verticality ntawm tooj liab electrode;

③ Xyuas kom meej tias qhov sib txawv ntawm cov riam khoob yog qhov sib npaug. Thaum pib machining, xyuas seb lub cuab yeej khoob puas yog offset txhua 0.2 hli txhua 3 mus rau 4 hli ntawm kev ua haujlwm. Yog tias qhov offset loj, nws yuav nyuaj los kho nws nrog kev hloov kho tom ntej;

④ Tshem tawm cov khoom seem tsim tawm thaum lub sijhawm EDM txheej txheem raws sijhawm. Spark paug corrosion yuav tsim ib tug loj npaum li cas ntawm residue, uas yuav tsum tau muab ntxuav nyob rau hauv lub sij hawm, txwv tsis pub lub sij hawm ntawm kev ua hauj lwm txoj siv yuav txawv vim qhov sib txawv heights ntawm cov residue;

⑤ Cov pwm yuav tsum tau demagnetized ua ntej EDM.

5. Kev sib piv ntawm cov txiaj ntsig extrusion

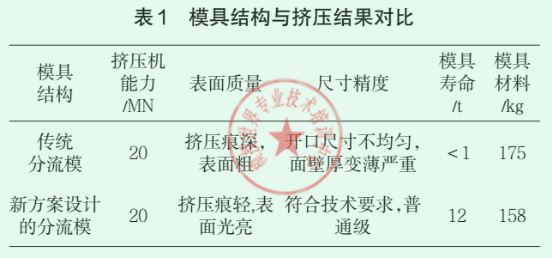

Cov profile uas muaj nyob rau hauv daim duab 1 tau sim siv cov tsoos phua pwm thiab cov qauv tsim tshiab uas tau npaj tseg hauv tsab xov xwm no. Kev sib piv ntawm cov txiaj ntsig tau qhia hauv Table 1.

Nws tuaj yeem pom los ntawm cov txiaj ntsig sib piv uas cov qauv pwm muaj kev cuam tshuam zoo rau lub neej pwm. Cov pwm tsim los siv cov tswv yim tshiab muaj qhov pom tseeb zoo thiab txhim kho pwm lub neej zoo heev.

6. Cov lus xaus

Sunflower radiator profile extrusion pwm yog hom pwm uas nyuaj heev rau kev tsim thiab tsim khoom, thiab nws cov qauv tsim thiab kev tsim khoom yog qhov nyuaj. Yog li ntawd, txhawm rau xyuas kom meej qhov kev ua tiav ntawm extrusion thiab kev pabcuam lub neej ntawm pwm, cov ntsiab lus hauv qab no yuav tsum ua tiav:

(1) Cov qauv ntawm cov pwm yuav tsum tau xaiv kom tsim nyog. Cov qauv ntawm cov pwm yuav tsum ua kom haum rau kev txo qis extrusion quab yuam kom txo qhov kev ntxhov siab ntawm cov pwm cantilever tsim los ntawm cov hniav kub dissipation, yog li txhim kho lub zog ntawm pwm. Qhov tseem ceeb yog kom txiav txim siab tus naj npawb thiab kev npaj ntawm shunt qhov thiab thaj tsam ntawm shunt qhov thiab lwm yam tsis: ua ntej, qhov dav ntawm shunt choj tsim ntawm lub shunt qhov yuav tsum tsis txhob ntau tshaj 16 hli; Qhov thib ob, qhov sib cais ntawm qhov chaw yuav tsum tau txiav txim siab kom qhov sib faib sib faib nce mus txog ntau dua 30% ntawm qhov sib piv extrusion ntau li ntau tau thaum ua kom lub zog ntawm pwm.

(2) Tsim nyog xaiv txoj siv sia ua haujlwm thiab ua raws li kev ntsuas tsim nyog thaum lub tshuab hluav taws xob, suav nrog kev siv tshuab ntawm tooj liab electrodes thiab cov qauv hluav taws xob tsis zoo ntawm cov tshuab hluav taws xob. Thawj lub ntsiab lus tseem ceeb yog qhov tooj liab electrode yuav tsum yog hauv av ua ntej xaim txiav, thiab txoj kev ntxig yuav tsum tau siv thaum lub sij hawm xaim txiav kom paub meej. Cov electrodes tsis xoob los yog deformed.

(3) Thaum lub sij hawm siv hluav taws xob machining txheej txheem, cov electrode yuav tsum raug ua kom raug kom tsis txhob muaj cov hniav sib txawv. Tau kawg, raws li kev tsim qauv tsim nyog thiab kev tsim khoom, kev siv cov khoom kub-ua haujlwm zoo pwm hlau thiab cov txheej txheem nqus cua sov ntawm peb lossis ntau dua tempers tuaj yeem ua kom muaj peev xwm ntawm pwm thiab ua tiav cov txiaj ntsig zoo dua. Los ntawm kev tsim, kev tsim khoom mus rau extrusion ntau lawm, tsuas yog tias txhua qhov txuas yog qhov tseeb tuaj yeem ua kom ntseeg tau tias cov paj noob hlis radiator profile pwm yog extruded.

Post lub sij hawm: Aug-01-2024