Taw qhia

Nrog rau txoj kev loj hlob ntawm kev lag luam automotive, kev ua lag luam rau aluminium alloy cuam tshuam kab teeb kuj tseem loj hlob sai, txawm tias tseem me me nyob rau hauv tag nrho loj. Raws li kev kwv yees los ntawm Automotive Lightweight Technology Innovation Alliance rau Suav aluminium alloy cuam tshuam kev lag luam, los ntawm 2025, kev lag luam xav tau kwv yees li ntawm 140,000 tons, nrog rau kev lag luam loj yuav tsum ncav cuag 4.8 billion RMB. Los ntawm 2030, kev lag luam xav tau kwv yees kwv yees li 220,000 tons, nrog kev kwv yees kev lag luam loj ntawm 7.7 billion RMB, thiab kev loj hlob txhua xyoo ntawm kwv yees li 13%. Txoj kev loj hlob ntawm lub teeb yuag thiab kev loj hlob sai ntawm nruab nrab-rau-high-end tsheb qauv yog qhov tseem ceeb tsav tsheb rau kev txhim kho aluminium alloy cuam tshuam kab teeb hauv Suav teb. Kev lag luam zeem muag rau tsheb cuam tshuam beam tsoo lub thawv muaj kev cia siab.

Raws li cov nqi txo thiab kev siv thev naus laus zis nce ntxiv, aluminium alloy pem hauv ntej cuam tshuam cov kab teeb thiab cov thawv sib tsoo tau maj mam dhau los. Tam sim no, lawv tau siv nyob rau hauv nruab nrab-rau-siab-kawg qauv tsheb xws li Audi A3, Audi A4L, BMW 3 series, BMW X1, Mercedes-Benz C260, Honda CR-V, Toyota RAV4, Buick Regal, thiab Buick LaCrosse.

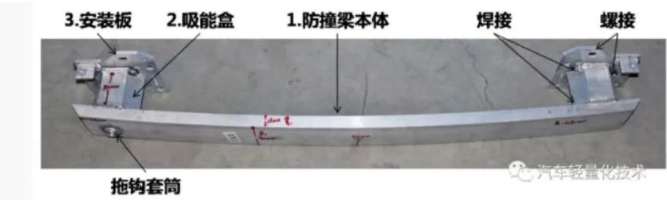

Aluminium alloy impact beams yog tsim los ntawm kev cuam tshuam crossbeams, sib tsoo lub thawv, mounting baseplates, thiab towing nuv lub tes tsho, raws li qhia hauv daim duab 1.

Daim duab 1: Aluminium Alloy Impact Beam Assembly

Lub thawv sib tsoo yog lub thawv hlau nyob nruab nrab ntawm cov kab hluav taws xob cuam tshuam thiab ob txoj kab ntev ntev ntawm lub tsheb, qhov tseem ceeb ua haujlwm raws li lub zog nqus ntim. Lub zog no hais txog lub zog ntawm kev cuam tshuam. Thaum lub tsheb ntsib kev sib tsoo, qhov cuam tshuam beam muaj qee yam ntawm lub zog nqus dej. Txawm li cas los xij, yog tias lub zog ntau tshaj qhov muaj peev xwm ntawm cov kab hluav taws xob cuam tshuam, nws yuav hloov lub zog mus rau lub thawv sib tsoo. Lub thawv sib tsoo absorbs tag nrho cov kev cuam tshuam quab yuam thiab deforms nws tus kheej, kom ntseeg tau tias cov kab ntev ntev nyob twj ywm tsis muaj kev puas tsuaj.

1 Cov khoom yuav tsum tau muaj

1.1 Dimensions yuav tsum ua raws li cov duab kos qhov yuav tsum tau ua siab ntev, raws li qhia hauv daim duab 2.

1.3 Mechanical Performance Requirements:

Tensile zog: ≥215 MPa

Tawm Zog: ≥205 MPa

Elongation A50: ≥10%

1.4 Crash Box Crushing Performance:

Raws li lub tsheb X-axis, siv qhov sib tsoo nto loj dua cov khoom hla ntu, thauj khoom ntawm qhov ceev ntawm 100 mm / min kom txog thaum crushing, nrog compression npaum li cas ntawm 70%. Thawj qhov ntev ntawm qhov profile yog 300 hli. Nyob rau ntawm qhov sib txuas ntawm cov hlua khi thiab cov phab ntsa sab nrauv, cov kab nrib pleb yuav tsum tsawg dua 15 hli kom pom tau tias tsim nyog. Nws yuav tsum tau ua kom ntseeg tau tias qhov kev tso cai tawg tsis cuam tshuam rau qhov profile ntawm crushing zog-absorbing peev xwm, thiab yuav tsum tsis txhob muaj cov kab nrib pleb tseem ceeb hauv lwm qhov chaw tom qab crushing.

2 Txoj Kev Txhim Kho

Txhawm rau kom ua tau raws li qhov yuav tsum tau ua ntawm kev siv tshuab thiab kev ua haujlwm crushing, txoj kev txhim kho yog raws li hauv qab no:

Siv 6063B pas nrig nrog thawj alloy muaj pes tsawg leeg ntawm Si 0.38-0.41% thiab Mg 0.53-0.60%.

Ua huab cua quenching thiab dag dag kom ua tiav T6 mob.

Ua haujlwm pos huab + huab cua quenching thiab ua kev kho mob dhau los kom ua tiav T7 mob.

3 Pilot Production

3.1 Extrusion Conditions

Kev tsim khoom yog nqa tawm ntawm 2000T extrusion xovxwm nrog ib qho piv txwv ntawm 36. Cov khoom siv yog homogenized aluminium rod 6063B. Cov cua kub cua sov ntawm aluminium pas nrig yog raws li nram no: IV zone 450-III zone 470-II zone 490-1 zone 500. Lub tog raj kheej lub tog raj kheej lub siab tawg yog nyob ib ncig ntawm 210 bar, nrog rau theem ruaj khov extrusion muaj qhov extrusion siab ze rau 180 bar. Lub extrusion ncej ceev yog 2.5 mm / s, thiab profile extrusion ceev yog 5.3 m / min. Qhov kub ntawm qhov hluav taws xob extrusion yog 500-540 ° C. Lub quenching yog ua tiav siv cua txias nrog rau sab laug kiv cua ntawm 100%, nruab nrab kiv cua ntawm 100%, thiab txoj cai kiv cua ntawm 50%. Qhov nruab nrab cua txias nyob rau hauv cheeb tsam quenching nce mus txog 300-350 ° C / min, thiab qhov kub tom qab tawm hauv thaj chaw quenching yog 60-180 ° C. Rau pos huab + huab cua quenching, qhov nruab nrab cua txias nyob rau hauv lub cua sov cheeb tsam mus txog 430-480 ° C / min, thiab kub tom qab tawm hauv lub quenching cheeb tsam yog 50-70 ° C. Qhov profile qhia tsis muaj qhov cuam tshuam loj.

3.2 Kev laus

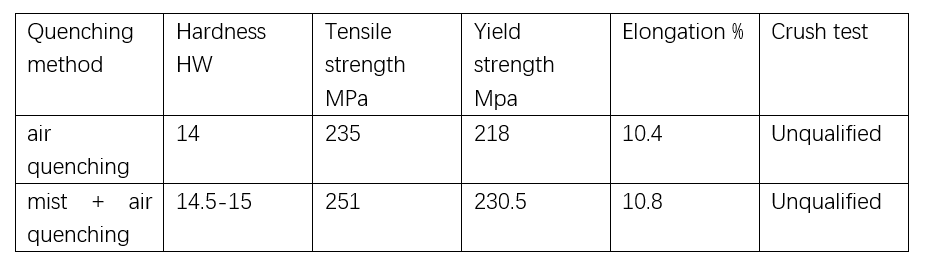

Ua raws li T6 txheej txheem kev laus ntawm 185 ° C rau 6 teev, cov khoom siv hardness thiab cov khoom siv tshuab yog raws li hauv qab no:

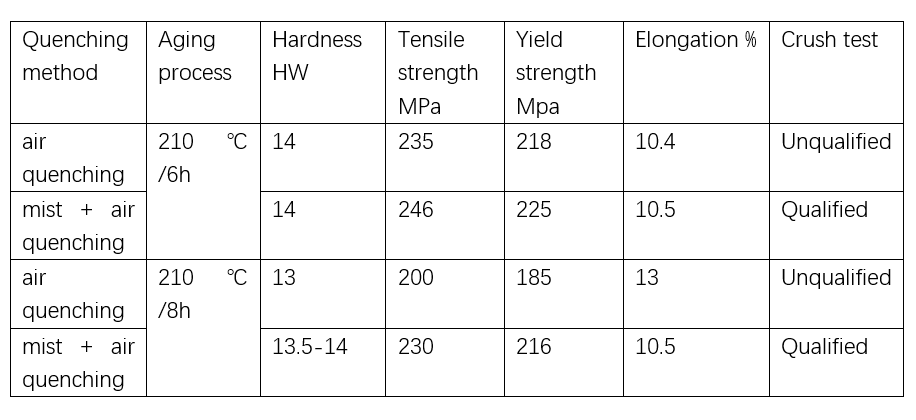

Raws li T7 txheej txheem kev laus ntawm 210 ° C rau 6 teev thiab 8 teev, cov khoom hardness thiab mechanical zog yog raws li nram no:

Raws li cov ntaub ntawv xeem, cov huab cua + cua quenching txoj kev, ua ke nrog 210 ° C / 6h txheej txheem kev laus, ua tau raws li qhov yuav tsum tau ua rau ob qho tib si kev ua tau zoo thiab kev sim crushing. Xav txog qhov ua tau zoo, qhov pos huab + cua quenching txoj kev thiab 210 ° C / 6h txheej txheem kev laus raug xaiv rau kev tsim khoom kom tau raws li cov khoom xav tau.

3.3 Crushing Test

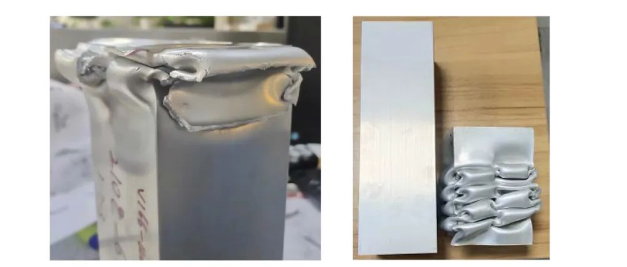

Rau qhov thib ob thiab thib peb rods, lub taub hau kawg yog txiav tawm los ntawm 1.5m, thiab tus Tsov tus tw kawg yog txiav tawm los ntawm 1.2m. Ob qhov qauv coj los ntawm lub taub hau, nruab nrab, thiab tus Tsov tus tw, nrog qhov ntev ntawm 300mm. Kev ntsuas kev sib tsoo yog ua tom qab kev laus ntawm 185 ° C / 6h thiab 210 ° C / 6h thiab 8h (cov ntaub ntawv kev ua tau zoo raws li tau hais los saum no) ntawm lub tshuab ntsuas khoom siv thoob ntiaj teb. Cov kev ntsuam xyuas tau ua nyob rau ntawm qhov ceev ntawm 100 mm / min nrog compression npaum li cas ntawm 70%. Cov txiaj ntsig tau muaj raws li hauv qab no: rau huab cua quenching nrog 210 ° C / 6h thiab 8h cov txheej txheem kev laus, cov kev sim crushing ua tau raws li qhov yuav tsum tau ua, raws li pom hauv daim duab 3-2, thaum cov qauv huab cua-quenched pom tawg rau tag nrho cov txheej txheem kev laus.

Raws li kev soj ntsuam crushing, pos huab + huab cua quenching nrog 210 ° C / 6h thiab 8h cov txheej txheem kev laus ua tau raws li cov neeg siv khoom xav tau.

4 Kev xaus

Kev ua kom zoo ntawm cov txheej txheem quenching thiab kev laus yog qhov tseem ceeb rau kev txhim kho kev ua tiav ntawm cov khoom thiab muab cov txheej txheem zoo tshaj plaws rau cov khoom sib tsoo.

Los ntawm kev sim dav dav, nws tau txiav txim siab tias cov khoom siv lub xeev rau cov khoom sib tsoo yuav tsum yog 6063-T7, txoj kev quenching yog pos huab + cua txias, thiab cov txheej txheem kev laus ntawm 210 ° C / 6h yog qhov kev xaiv zoo tshaj plaws rau extruding aluminium rods nrog kub ntawm 480-500 ° C, extrusion. 480 ° C, thiab extrusion qhov hluav taws xob kub ntawm 500-540 ° C.

Kho los ntawm May Jiang los ntawm MAT Aluminium

Post lub sij hawm: May-07-2024