1 Kev piav qhia ntawm qhov tsis xws luag

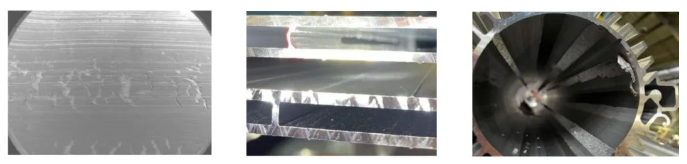

Thaum extruding kab noj hniav profiles, lub taub hau yog ib txwm khawb, thiab tus nqi puas yog yuav luag 100%. Cov qauv tsis xws luag ntawm qhov profile yog raws li hauv qab no:

2 Kev tsom xam ua ntej

2.1 Kev txiav txim los ntawm qhov chaw ntawm qhov tsis xws luag thiab cov duab ntawm qhov tsis xws luag, nws yog delamination thiab tev.

2.2 Ua rau: Vim tias daim tawv nqaij ntawm tus pas nrig ua ntej tau dov rau hauv pwm kab noj hniav, tsis sib haum, tev, thiab cov khoom rotten tshwm ntawm lub taub hau extrusion ntawm tus pas nrig tom ntej.

3 Kev txheeb xyuas thiab kev txheeb xyuas

Electron microscope scans ntawm qis magnification, siab magnification thiab cross-sectional defects ntawm tus pas nrig casting tau ua raws.

3.1 Casting pas nrig qis magnification

11 nti 6060 casting pas nrig qis magnification Nto 6.08mm

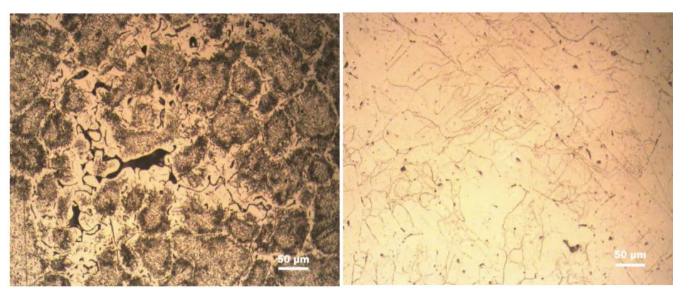

3.2 Casting pas nrig siab magnification

Ze rau lub epidermis Segregation txheej faib kab qhov chaw

Casting pas nrig 1/2 txoj hauj lwm

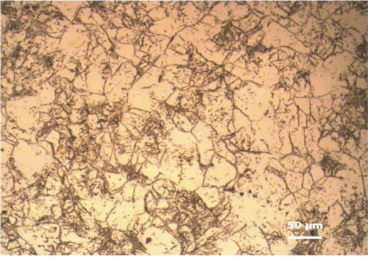

3.3 Electron microscope scanning defects

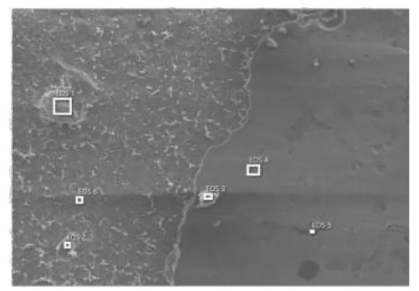

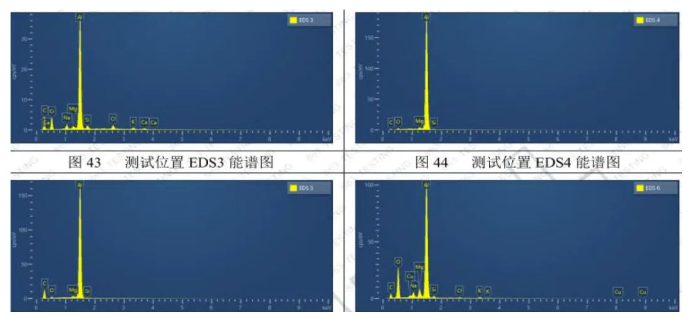

Magnify qhov chaw tsis raug 200 zaug

Lub zog spectrum daim duab

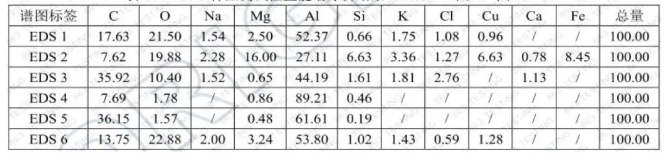

EDS cov ntsiab lus tsom xam

4 Cov lus piav qhia luv luv ntawm kev txheeb xyuas cov txiaj ntsig

4.1 A 6mm tuab txheej txheej tshwm sim ntawm qhov qis-magnification nto ntawm tus pas nrig casting. Kev sib cais yog qhov qis-melting-point eutectic, tshwm sim los ntawm undercooling ntawm casting. Cov tsos ntawm macroscopic yog dawb thiab ci, thiab ciam teb nrog cov matrix yog qhov tseeb;

4.2 High magnification qhia tau hais tias muaj pores nyob rau ntawm ntug ntawm lub casting pas nrig, qhia tau hais tias lub txias siv yog siab dhau heev lawm thiab cov kua txhuas yog tsis pub txaus. Ntawm qhov sib cuam tshuam ntawm cov txheej txheem cais thiab cov matrix, theem ob yog qhov tsis tshua muaj thiab tsis txuas ntxiv, uas yog thaj chaw tsis zoo. Txoj kab uas hla ntawm lub pas nrig casting yog 1/2 Lub xub ntiag ntawm dendrites ntawm qhov chaw thiab qhov tsis sib xws ntawm cov khoom sib txuas ntxiv qhia txog kev sib cais ntawm cov txheej txheej saum npoo thiab cov xwm txheej rau kev loj hlob ntawm dendrites;

4.3 Diam duab ntawm qhov kev tsis sib haum xeeb nyob rau hauv 200x daim teb ntawm kev pom ntawm lub tshuab ntsuas hluav taws xob pom tau hais tias lub ntsej muag yog qhov ntxhib ntawm daim tawv nqaij, thiab qhov chaw yog du qhov twg daim tawv nqaij tsis tev. Tom qab EDS muaj pes tsawg leeg tsom xam, cov ntsiab lus 1, 2, 3, thiab 6 yog qhov chaw tsis xws luag, thiab cov muaj pes tsawg leeg muaj C1, K, thiab Na yog peb lub ntsiab lus, qhia tias muaj cov khoom ua kom zoo hauv cov khoom sib xyaw;

4.4 C thiab 0 cov khoom nyob rau hauv cov khoom ntawm cov ntsiab lus 1, 2, thiab 6 yog siab dua, thiab Mg, Si, Cu, thiab Fe Cheebtsam ntawm point 2 yog siab dua li cov ntsiab lus 1 thiab 6, qhia tias qhov muaj pes tsawg leeg ntawm qhov chaw tsis sib xws thiab muaj cov impurities cuam tshuam;

4.5 Kev soj ntsuam xyuas cov ntsiab lus ntawm cov ntsiab lus 2 thiab 3 thiab pom tias cov khoom muaj Ca lub hauv paus, qhia tau hais tias cov hmoov talcum tau koom nrog hauv qhov chaw ntawm txhuas pas nrig thaum lub sij hawm casting txheej txheem.

5 Cov ntsiab lus

Tom qab kev soj ntsuam saum toj no, nws tuaj yeem pom tau tias vim muaj kev sib cais, tus neeg sawv cev ua kom zoo, talcum hmoov thiab slag suav nrog rau ntawm qhov chaw ntawm txhuas pas nrig, qhov muaj pes tsawg leeg tsis sib xws, thiab daim tawv nqaij tau dov rau hauv pwm kab noj hniav thaum lub sij hawm extrusion, ua rau muaj kev puas tsuaj ntawm lub taub hau. Los ntawm kev txo qis qhov kub ntawm cov pas nrig casting thiab thickening residual thickness, lub tev thiab crushing teeb meem yuav raug txo los yog txawm daws tau; Qhov kev ntsuas zoo tshaj plaws yog ntxiv lub tshuab ziab khaub ncaws rau tev thiab extrusion.

Kho los ntawm May Jiang los ntawm MAT Aluminium

Post lub sij hawm: Jun-12-2024