1. Taw qhia

Automotive lightweighting pib nyob rau hauv lub teb chaws tsim thiab tau pib coj los ntawm cov tsoos automotive giants. Nrog kev txhim kho tas mus li, nws tau txais lub zog tseem ceeb. Txij li thaum cov neeg Isdias Asmesliskas thawj zaug siv aluminium alloy los tsim tsheb crankshafts rau Audi thawj qhov loj ntawm tag nrho cov tsheb txhuas hauv xyoo 1999, aluminium alloy tau pom kev loj hlob zoo hauv kev siv tsheb vim nws qhov zoo xws li tsis tshua muaj siab, muaj zog tshwj xeeb thiab nruj, zoo elasticity thiab cuam tshuam tsis kam, siab recyclability, thiab siab regeneration tus nqi. Los ntawm 2015, daim ntawv thov feem ntawm aluminium alloy nyob rau hauv tsheb twb dhau 35%.

Tuam Tshoj lub tsheb teeb pom kev zoo tau pib tsawg dua 10 xyoo dhau los, thiab ob qho tib si thev naus laus zis thiab kev siv qib lag luam qis dua cov teb chaws tsim kho xws li lub teb chaws Yelemees, Tebchaws Meskas, thiab Nyij Pooj. Txawm li cas los xij, nrog txoj kev loj hlob ntawm lub zog tshiab tsheb, cov khoom siv teeb pom kev zoo tau nce sai. Leveraging qhov nce ntawm lub zog tshiab tsheb, Tuam Tshoj tus automotive lightweighting technology yog qhia ib tug qauv ntawm catch up nrog rau cov teb chaws tsim.

Tuam Tshoj lub teeb khoom lag luam yog loj heev. Ntawm qhov tod tes, piv nrog cov teb chaws tsim tawm txawv teb chaws, Tuam Tshoj lub teeb yuag thev naus laus zis tau pib lig, thiab tag nrho lub tsheb Curb hnyav dua. Xav txog qhov ntsuas ntawm cov khoom siv hnyav 'kev faib ua feem hauv txawv teb chaws, tseem muaj chaw txaus rau kev loj hlob hauv Suav teb. Ntawm qhov tod tes, tau tsav los ntawm cov cai, txoj kev loj hlob sai ntawm Tuam Tshoj txoj kev lag luam tsheb tshiab lub zog yuav txhawb nqa qhov kev thov rau cov khoom siv hnyav thiab txhawb nqa cov tuam txhab tsheb kom txav mus rau qhov hnyav.

Kev txhim kho ntawm emissions thiab roj noj cov qauv yog yuam kom acceleration ntawm automotive lightweighting. Tuam Tshoj tau ua tiav raws li Tuam Tshoj VI emission qauv nyob rau xyoo 2020. Raws li "Kev Ntsuas Kev Ntsuas thiab Cov Ntsuas Ntsuas Kev Siv Roj Ntawm Cov Tsheb Tsheb" thiab "Kev txuag hluav taws xob thiab Kev Siv Hluav Taws Xob Tshiab Txoj Kev Siv Hluav Taws Xob," tus qauv 5.0 L / km roj noj. Muab rau hauv tus account qhov chaw txwv tsis pub muaj kev cuam tshuam loj hauv lub tshuab thev naus laus zis thiab kev txo qis emissions, siv cov kev ntsuas rau cov khoom siv tsheb sib sib zog tuaj yeem txo cov tsheb emissions thiab roj noj. Lub teeb yuag ntawm lub zog tshiab tsheb tau dhau los ua txoj hauv kev tseem ceeb rau kev lag luam txoj kev loj hlob.

Xyoo 2016, Tuam Tshoj Automotive Engineering Society tau tshaj tawm "Kev txuag hluav taws xob thiab lub zog tshiab tsheb thev naus laus zis Roadmap," uas tau npaj cov yam ntxwv xws li kev siv hluav taws xob, kev caij nkoj, thiab kev tsim cov khoom siv rau lub zog tshiab tsheb los ntawm 2020 txog 2030. Kev sib sib zog nqus yuav yog ib qho kev taw qhia tseem ceeb rau kev txhim kho lub zog tshiab rau yav tom ntej. Lub teeb yuag tuaj yeem ua rau muaj kev caij nkoj ntau ntxiv thiab hais txog "kev ntxhov siab ntau" hauv cov tsheb tshiab. Nrog rau qhov kev thov nce ntxiv rau kev caij nkoj mus ntev, kev siv tsheb thauj mus los tau ceev ceev, thiab kev muag khoom ntawm lub zog tshiab tsheb tau loj hlob hauv xyoo tas los no. Raws li qhov yuav tsum tau ua ntawm cov qhab-nees system thiab "Ib nrab-rau-Long-Tsev Kev Npaj Npaj rau Kev Lag Luam Automotive," nws tau kwv yees tias los ntawm 2025, Tuam Tshoj txoj kev muag khoom ntawm lub zog tshiab yuav dhau 6 lab units, nrog rau kev loj hlob txhua xyoo ntau dua 38%.

2.Aluminium Alloy yam ntxwv thiab kev siv

2.1 Yam ntxwv ntawm Aluminium Alloy

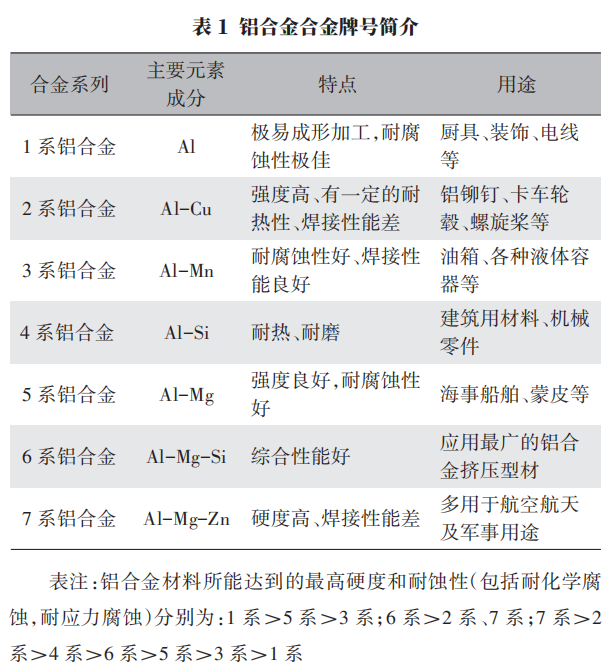

Qhov ntom ntawm aluminium yog ib feem peb ntawm cov hlau, ua rau nws sib zog. Nws muaj lub zog tshwj xeeb dua, muaj peev xwm extrusion zoo, muaj zog corrosion kuj, thiab siab rov ua dua tshiab. Aluminium alloys yog tus yam ntxwv los ntawm qhov tseem ceeb ntawm magnesium, nthuav tawm cov cua sov zoo, cov khoom siv vuam zoo, zoo qaug zog, tsis muaj peev xwm ua kom muaj zog los ntawm kev kho cua sov, thiab muaj peev xwm ua kom muaj zog los ntawm kev ua haujlwm txias. Lub 6 series yog tus cwj pwm los ntawm kev ua haujlwm feem ntau ntawm magnesium thiab silicon, nrog Mg2Si ua lub zog tseem ceeb. Feem ntau siv alloys hauv pawg no yog 6063, 6061, thiab 6005A. 5052 txhuas phaj yog AL-Mg series alloy txhuas phaj, nrog magnesium ua lub ntsiab alloying. Nws yog feem ntau siv los tiv thaiv xeb aluminium alloy. Cov hlau no muaj lub zog siab, siab qaug zog, zoo plasticity thiab corrosion kuj, tsis tuaj yeem ntxiv dag zog los ntawm kev kho cua sov, muaj cov yas zoo hauv kev ua haujlwm txias txias, tsis tshua muaj plasticity hauv kev ua haujlwm txias, zoo corrosion kuj, thiab zoo vuam zog. Nws yog tsuas yog siv rau cov khoom xws li sab panels, ru tsev npog, thiab lub qhov rooj panels. 6063 aluminium alloy yog lub tshav kub-kho tau ntxiv dag zog alloy hauv AL-Mg-Si series, nrog magnesium thiab silicon ua cov ntsiab lus tseem ceeb alloying. Nws yog lub tshav kub-kho tau ntxiv dag zog aluminium alloy profile nrog nruab nrab lub zog, feem ntau yog siv rau hauv cov khoom siv xws li kab thiab sab vaj huam sib luag los nqa lub zog. Kev taw qhia txog qib aluminium alloy yog qhia hauv Table 1.

2.2 Extrusion yog ib qho tseem ceeb tsim txoj kev ntawm Aluminium Alloy

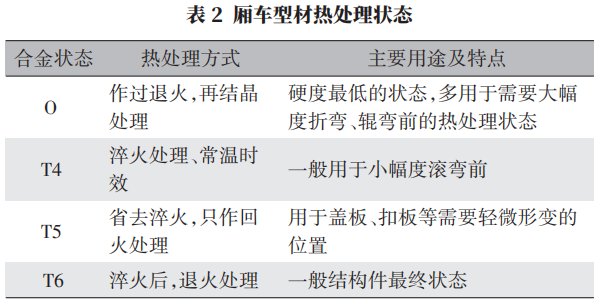

Aluminium alloy extrusion yog ib txoj kev kub kub, thiab tag nrho cov txheej txheem ntau lawm koom nrog kev tsim aluminium alloy nyob rau hauv peb txoj kev compressive kev nyuaj siab. Tag nrho cov txheej txheem tsim khoom tuaj yeem piav qhia raws li hauv qab no: a. Aluminium thiab lwm yam alloys yog melted thiab cam khwb cia rau hauv qhov yuav tsum tau aluminium alloy billets; b. Preheated billets muab tso rau hauv cov khoom siv extrusion rau extrusion. Nyob rau hauv qhov kev txiav txim ntawm lub ntsiab lub tog raj kheej, lub txhuas alloy billet yog tsim rau hauv cov kev xav tau profiles los ntawm kab noj hniav ntawm pwm; c. Txhawm rau txhim kho cov khoom siv hluav taws xob ntawm aluminium profiles, kev kho kev daws teeb meem yog nqa tawm thaum lub sij hawm los yog tom qab extrusion, ua raws li kev laus kev kho mob. Cov khoom siv kho tshuab tom qab kev laus kho tau sib txawv raws li cov khoom sib txawv thiab cov txheej txheem kev laus. Kev kho cua sov txheej xwm ntawm lub thawv-hom tsheb profiles yog qhia hauv Table 2.

Aluminium alloy extruded khoom muaj ntau qhov zoo dua lwm txoj hauv kev:

ib. Thaum lub sij hawm extrusion, cov hlau extruded tau txais ib tug muaj zog thiab ntau yam zoo li peb-txoj kev compressive kev nyuaj siab nyob rau hauv lub deformation cheeb tsam tshaj dov thiab forging, yog li nws muaj peev xwm ua si tag nrho cov plasticity ntawm cov txheej txheem hlau. Nws tuaj yeem siv los ua cov txheej txheem nyuaj-rau-deform hlau uas tsis tuaj yeem ua tiav los ntawm dov lossis forging thiab tuaj yeem siv los ua ntau yam sib txawv hollow lossis cov khoom hla ntu.

b. Vim hais tias cov geometry ntawm aluminium profiles tuaj yeem sib txawv, lawv cov khoom muaj qhov nruj, uas tuaj yeem txhim kho qhov nruj ntawm lub cev lub cev, txo nws cov NVH cov yam ntxwv, thiab txhim kho lub tsheb dynamic tswj cov yam ntxwv.

c. Cov khoom lag luam nrog extrusion efficiency, tom qab quenching thiab aging, muaj ntau dua longitudinal zog (R, Raz) dua cov khoom ua los ntawm lwm txoj kev.

d. Qhov saum npoo ntawm cov khoom tom qab extrusion muaj cov xim zoo thiab zoo corrosion kuj, tshem tawm qhov xav tau rau lwm yam kev tiv thaiv corrosion nto.

e. Extrusion txheej txheem muaj qhov yooj yooj yim, tsis tshua muaj cuab yeej thiab pwm cov nqi, thiab cov nqi hloov tsim qis.

f. Vim lub controllability ntawm txhuas profile cross-sections, lub degree ntawm tivthaiv kev koom ua ke yuav tsum tau nce, tus naj npawb ntawm cov Cheebtsam yuav raug txo, thiab txawv cross-section designs yuav ua tau meej vuam positioning.

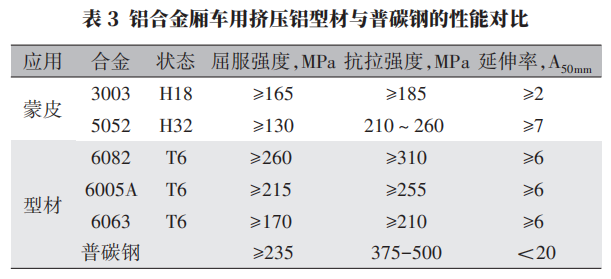

Kev sib piv ntawm kev ua tau zoo ntawm extruded aluminium profiles rau lub thawv-hom tsheb thauj khoom thiab cov pa roj carbon steel yog qhia hauv Table 3.

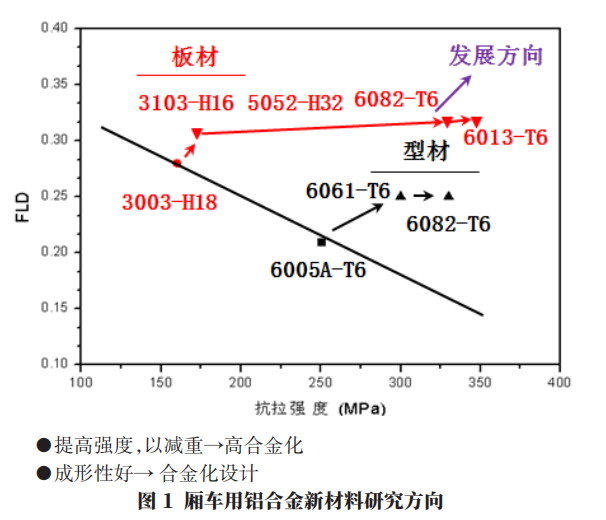

Tom ntej no Kev Txhim Kho Kev Taw Qhia ntawm Aluminium Alloy Profiles rau Box-type Trucks: Ntxiv kev txhim kho profile zog thiab txhim kho kev ua haujlwm extrusion. Kev tshawb fawb kev taw qhia ntawm cov ntaub ntawv tshiab rau aluminium alloy profiles rau lub thawv-hom tsheb yog qhia hauv daim duab 1.

3.Aluminium Alloy Box Truck Structure, Kev Ntsuam Xyuas Lub Zog, thiab Kev Tshawb Fawb

3.1 Aluminium Alloy Box Truck Structure

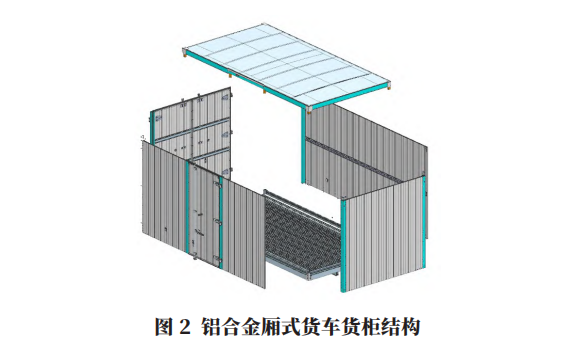

Lub thawv tsheb thauj khoom feem ntau suav nrog kev sib dhos pem hauv ntej vaj huam sib luag, sab laug thiab sab xis vaj huam sib luag sib dhos, lub qhov rooj sab hauv vaj huam sib luag, pem teb sib dhos, lub ru tsev sib dhos, nrog rau U-shaped bolts, sab guards, rear guards, av flaps, thiab lwm yam khoom siv txuas nrog lub chassis thib ob. Lub thawv lub cev hla kab kab, ncej, sab kab teeb, thiab lub qhov rooj vaj huam sib luag yog ua los ntawm aluminium alloy extruded profiles, thaum hauv pem teb thiab lub ru tsev panels yog ua los ntawm 5052 aluminium alloy tiaj daim hlau. Cov qauv ntawm aluminium alloy lub thawv tsheb yog qhia hauv daim duab 2.

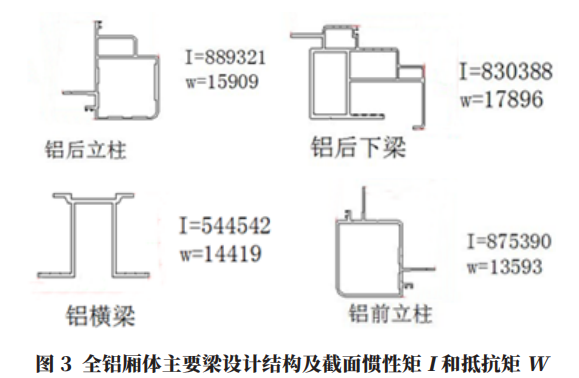

Siv cov txheej txheem kub extrusion ntawm 6 series aluminium alloy tuaj yeem tsim cov hollow cross-sections, tsim cov aluminium profiles nrog cov ntu ntu tuaj yeem txuag cov ntaub ntawv, ua tau raws li qhov yuav tsum tau ua ntawm cov khoom muaj zog thiab nruj, thiab ua tau raws li qhov yuav tsum tau muaj kev sib txuas ntawm ntau yam khoom. Yog li ntawd, lub ntsiab beam tsim qauv thiab ntu ntu ntawm inertia I thiab resisting moments W yog qhia hauv daim duab 3.

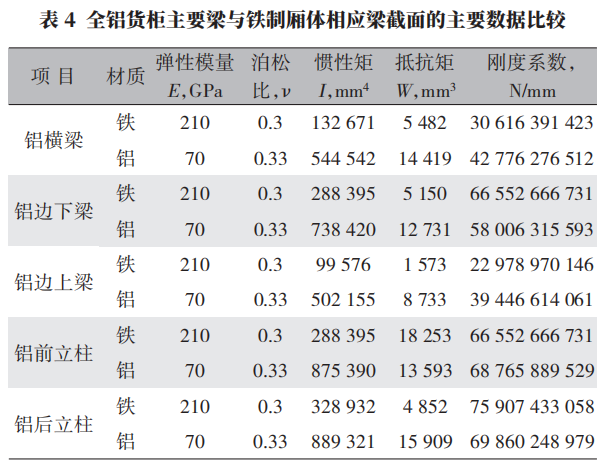

Kev sib piv ntawm cov ntaub ntawv tseem ceeb nyob rau hauv Table 4 qhia tau hais tias lub sij hawm seem ntawm inertia thiab resisting lub sij hawm ntawm tus tsim aluminium profile zoo dua li cov ntaub ntawv sib raug ntawm cov hlau ua beam profile. Cov ntaub ntawv nruj coefficient yog roughly tib yam li cov ntawm cov hlau-ua beam profile, thiab tag nrho cov ua tau raws li qhov yuav tsum tau deformation.

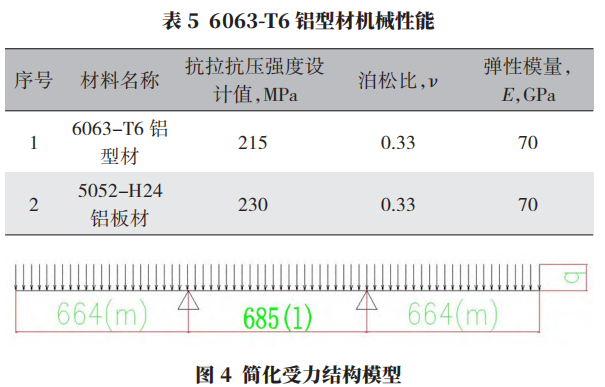

3.2 Kev ntsuas kev nyuaj siab tshaj plaws

Noj qhov tseem ceeb load-bearing tivthaiv, lub crossbeam, raws li cov khoom, lub siab tshaj plaws kev nyuaj siab yog xam. Qhov ntsuas load yog 1.5 t, thiab lub crossbeam yog ua los ntawm 6063-T6 aluminium alloy profile nrog txhua yam khoom raws li qhia nyob rau hauv Table 5. Lub beam yog yooj yim raws li ib tug cantilever qauv rau quab yuam xam, raws li nyob rau hauv daim duab 4.

Noj 344mm span beam, compressive load ntawm lub beam yog xam raws li F = 3757 N raws li 4.5t, uas yog peb npaug ntawm tus qauv zoo li qub load. q = F/L

qhov twg q yog qhov kev ntxhov siab sab hauv ntawm lub nqaj nyob rau hauv lub load, N / mm; F yog cov khoom thauj los ntawm cov nqaj, xam raws li 3 npaug ntawm tus qauv zoo li qub, uas yog 4.5 t; L yog qhov ntev ntawm lub nqaj, mm.

Yog li ntawd, lub internal stress q yog:

Cov qauv kev ntsuas kev ntxhov siab yog raws li hauv qab no:

Lub sijhawm siab tshaj plaws yog:

Noj cov nqi tam sim no, M = 274283 N·mm, qhov siab tshaj plaws kev ntxhov siab σ = M / (1.05 × w) = 18.78 MPa, thiab qhov siab tshaj plaws tus nqi σ< 215 MPa, uas ua tau raws li qhov yuav tsum tau ua.

3.3 Kev sib txuas yam ntxwv ntawm ntau yam khoom siv

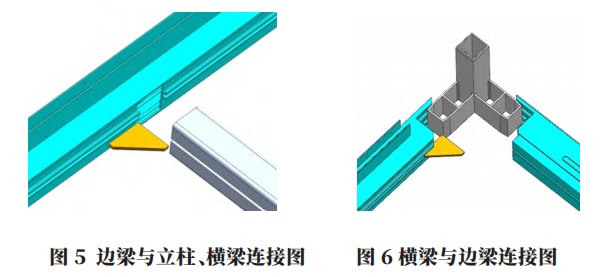

Aluminium alloy muaj cov khoom siv vuam tsis zoo, thiab nws qhov vuam taw tes lub zog tsuas yog 60% ntawm cov khoom siv lub zog. Vim yog npog ntawm ib txheej ntawm Al2O3 ntawm aluminium alloy nto, lub melting point ntawm Al2O3 yog siab, thaum lub melting point ntawm txhuas yog tsawg. Thaum aluminium alloy yog welded, Al2O3 ntawm qhov chaw yuav tsum tau tawg sai sai los ua vuam. Nyob rau tib lub sijhawm, cov seem ntawm Al2O3 yuav nyob twj ywm hauv cov tshuaj aluminium alloy, cuam tshuam rau aluminium alloy qauv thiab txo lub zog ntawm aluminium alloy vuam taw tes. Yog li ntawd, thaum tsim ib lub thawv txhuas txhuas, cov yam ntxwv no tau txiav txim siab tag nrho. Vuam yog txoj hauv kev ua haujlwm tseem ceeb, thiab cov khoom tseem ceeb ntawm cov kabmob yog txuas nrog bolts. Kev sib txuas xws li riveting thiab dovetail qauv yog qhia nyob rau hauv daim duab 5 thiab 6.

Lub ntsiab qauv ntawm tag nrho-aluminium lub cev lub cev txais cov qauv nrog kab rov tav kab, ntsug ncej, sab kab teeb, thiab ntug kab teeb sib cuam tshuam nrog ib leeg. Muaj plaub qhov kev sib txuas ntawm txhua kab kab rov tav thiab ntsug ncej. Cov ntsiab lus sib txuas yog haum nrog serrated gaskets rau mesh nrog serrated ntug ntawm kab rov tav kab rov tav, zoo tiv thaiv zawv zawg. Lub kaum sab xis yog feem ntau txuas nrog steel core inserts, tsau nrog bolts thiab nws tus kheej-locking rivets, thiab ntxiv dag zog los ntawm 5 hli daim duab peb sab aluminium daim hlau welded hauv lub thawv kom ntxiv dag zog rau kaum txoj haujlwm sab hauv. Cov tsos ntawm sab nraud ntawm lub thawv tsis muaj vuam lossis nthuav tawm cov ntsiab lus sib txuas, kom ntseeg tau tias tag nrho cov tsos ntawm lub thawv.

3.4 SE Synchronous Engineering Technology

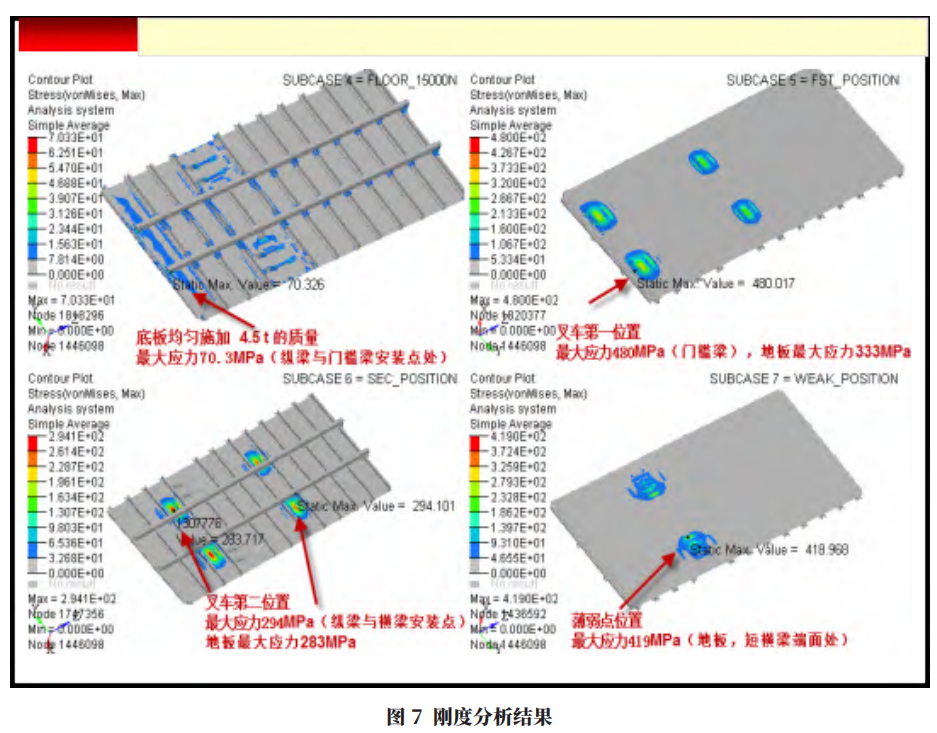

SE synchronous engineering thev naus laus zis yog siv los daws cov teeb meem tshwm sim los ntawm qhov sib txawv loj ntawm qhov sib txawv rau qhov sib piv cov khoom hauv lub thawv lub cev thiab cov teeb meem hauv kev nrhiav qhov ua rau qhov khoob thiab qhov tsis zoo. Los ntawm CAE kev tshuaj xyuas (saib daim duab 7-8), kev soj ntsuam kev sib piv yog ua nrog cov hlau ua lub thawv los xyuas tag nrho lub zog thiab qhov tawv nqaij ntawm lub cev lub cev, nrhiav cov ntsiab lus tsis muaj zog, thiab ntsuas kev ua kom zoo thiab txhim kho cov qauv tsim kom zoo dua.

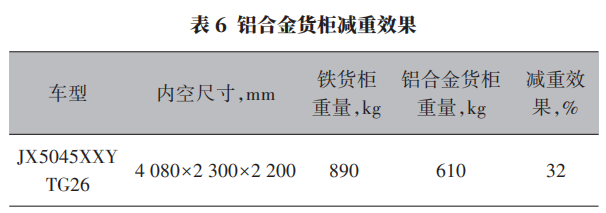

4.Lightweighting nyhuv ntawm Aluminium Alloy Box Truck

Ntxiv rau lub thawv lub cev, aluminium alloys tuaj yeem siv los hloov cov hlau rau ntau yam khoom ntawm lub thawv-hom tsheb thauj khoom, xws li mudguards, rear guards, side guards, door latches, door hinges, and rear apron edges, after the weight loss of 30% to 40% for the cargo compartment. Cov nyhuv txo qhov hnyav rau qhov khoob 4080mm × 2300mm × 2200mm cargo thawv yog muaj nyob rau hauv Table 6. Qhov no pab daws cov teeb meem ntawm qhov hnyav hnyav, tsis ua raws li cov lus tshaj tawm, thiab kev tswj hwm kev pheej hmoo ntawm cov khoom siv hlau ua cov khoom siv.

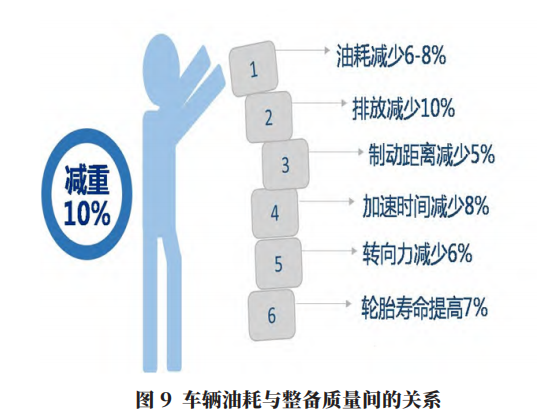

Los ntawm kev hloov cov tsoos hlau nrog aluminium alloys rau cov khoom siv tsheb, tsis tsuas yog tuaj yeem ua tiav cov teeb pom kev zoo, tab sis nws kuj tuaj yeem ua rau kev txuag roj, txo qis, thiab txhim kho lub tsheb ua haujlwm. Tam sim no, muaj ntau yam kev xav txog kev koom tes ntawm lub teeb yuag rau kev txuag roj. Cov txiaj ntsig kev tshawb fawb ntawm International Aluminium lub koom haum tau pom nyob rau hauv daim duab 9. Txhua txhua 10% txo cov tsheb hnyav tuaj yeem txo cov roj noj los ntawm 6% mus rau 8%. Raws li kev txheeb cais hauv tsev, txo qhov hnyav ntawm txhua tus neeg caij tsheb los ntawm 100 kg tuaj yeem txo cov roj noj los ntawm 0.4 L / 100 km. Kev koom tes ntawm kev sib tw rau kev txuag roj yog nyob ntawm cov txiaj ntsig tau los ntawm ntau txoj kev tshawb fawb, yog li muaj qee qhov kev hloov pauv. Txawm li cas los xij, automotive lightweighting muaj feem cuam tshuam rau kev txo cov roj noj.

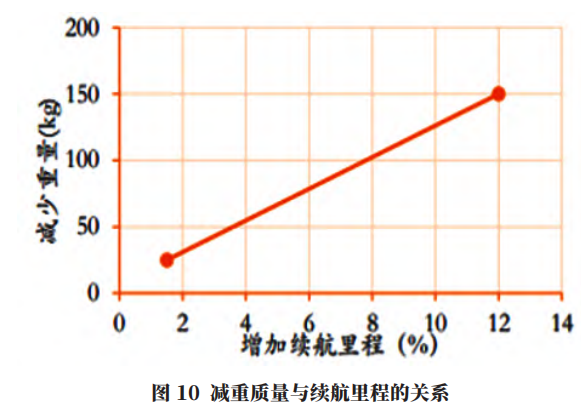

Rau cov tsheb fais fab, lub teeb yuag ua rau muaj kev cuam tshuam ntau dua. Tam sim no, chav tsev zog ceev ntawm lub tsheb fais fab fais fab roj teeb yog qhov sib txawv ntawm cov tsheb ua kua roj. Qhov hnyav ntawm lub zog hluav taws xob (suav nrog lub roj teeb) ntawm lub tsheb hluav taws xob feem ntau suav txog 20% txog 30% ntawm tag nrho cov tsheb hnyav. Nyob rau tib lub sijhawm, kev tawg los ntawm kev ua haujlwm tsis zoo ntawm cov roj teeb yog qhov kev sib tw thoob ntiaj teb. Ua ntej muaj kev ua tiav loj hauv kev ua haujlwm siab ntawm cov roj teeb thev naus laus zis, lub teeb yuag yog ib txoj hauv kev zoo los txhim kho kev caij nkoj ntawm cov tsheb fais fab. Rau txhua txhua 100 kg txo qhov hnyav, lub caij nkoj ntawm lub tsheb fais fab tuaj yeem nce los ntawm 6% mus rau 11% (qhov kev sib raug zoo ntawm kev txo qhov hnyav thiab kev caij nkoj yog pom hauv daim duab 10). Tam sim no, kev caij nkoj ntawm cov tsheb fais fab tsis tuaj yeem ua tau raws li qhov xav tau ntawm cov neeg feem coob, tab sis txo qhov hnyav los ntawm qee tus nqi tuaj yeem txhim kho qhov kev caij nkoj loj, txo ntau qhov kev ntxhov siab thiab txhim kho cov neeg siv kev paub.

5. Cov lus xaus

Ntxiv rau cov qauv txhuas txhuas ntawm aluminium alloy lub thawv tsheb tau qhia hauv tsab xov xwm no, muaj ntau hom tsheb thauj khoom, xws li aluminium honeycomb panels, aluminium buckle plates, aluminium thav duab + aluminium tawv, thiab hlau-aluminium hybrid cargo ntim. Lawv muaj qhov zoo ntawm lub teeb yuag, lub zog tshwj xeeb, thiab zoo corrosion kuj, thiab tsis tas yuav tsum muaj cov xim electrophoretic rau kev tiv thaiv corrosion, txo qhov cuam tshuam ib puag ncig ntawm cov xim electrophoretic. Aluminium alloy lub thawv tsheb hauv paus daws teeb meem ntawm qhov hnyav hnyav, tsis ua raws li cov lus tshaj tawm, thiab kev tswj hwm kev pheej hmoo ntawm cov tsoos hlau ua cov khoom thauj khoom.

Extrusion yog ib qho tseem ceeb ua txheej txheem rau txhuas alloys, thiab txhuas profiles muaj zoo heev mechanical zog, yog li cov seem nruj ntawm cov khoom yog kuj siab. Vim muaj qhov sib txawv ntawm qhov sib txawv, aluminium alloys tuaj yeem ua tiav kev sib xyaw ua ke ntawm ntau yam kev ua haujlwm, ua rau nws yog ib qho khoom siv zoo rau lub teeb yuag. Txawm li cas los xij, kev siv dav dav ntawm aluminium alloys ntsib cov teeb meem xws li kev tsim tsis txaus rau aluminium alloy cargo compartments, tsim thiab vuam teeb meem, thiab kev txhim kho siab thiab nce nqi rau cov khoom tshiab. Qhov laj thawj tseem ceeb yog qhov tseem ceeb ntawm aluminium alloy nqi ntau dua li cov hlau ua ntej cov ecology ntawm txhuas alloys ua kom paub tab.

Hauv kev xaus, daim ntawv thov ntawm aluminium alloys hauv tsheb yuav ua kom dav dua, thiab lawv cov kev siv yuav nce ntxiv. Nyob rau hauv lub tam sim no tiam sis ntawm lub zog txuag, emission txo, thiab kev loj hlob ntawm lub tshiab lub zog tsheb kev lag luam, nrog rau kev nkag siab tob ntawm aluminium alloy cov khoom thiab cov kev daws teeb meem zoo rau aluminium alloy daim ntawv thov teeb meem, aluminium extrusion cov ntaub ntawv yuav ntau lug siv nyob rau hauv automotive lightweighting.

Kho los ntawm May Jiang los ntawm MAT Aluminium

Post lub sij hawm: Jan-12-2024