Qhov laj thawj yog vim li cas cov proflex profiles tau siv dav nyob rau hauv lub neej thiab kev tsim tawm hluav taws xob zoo xws li txhua tus zoo hluav taws xob, cov khoom siv tsis muaj txiaj ntsig, thiab rov ua dua tshiab.

Tuam Tshoj txoj kev lag luam aluminium profile tau loj hlob los ntawm kos, los ntawm me me mus rau qhov loj, kom txog rau thaum nws tau tsim los ua ib lub teb chaws loj aluminium profile ntau lawm, nrog cov khoom tso tawm thawj zaug hauv ntiaj teb. Txawm li cas los xij, raws li kev lag luam yuav tsum tau ua rau cov khoom siv txhuas profile txuas ntxiv mus ntxiv, kev tsim cov txhuas profile tau tsim nyob rau hauv cov kev taw qhia ntawm complexity, high precision, thiab loj-scale ntau lawm, uas tau coj ib tug series ntawm ntau lawm teeb meem.

Aluminium profiles feem ntau yog tsim los ntawm extrusion. Thaum lub sij hawm tsim khoom, ntxiv rau kev xav txog kev ua tau zoo ntawm extruder, tsim pwm, muaj pes tsawg leeg ntawm txhuas pas nrig, kev kho cua sov thiab lwm yam txheej txheem, kev tsim cov ntu ntu ntawm qhov profile yuav tsum tau txiav txim siab. Qhov zoo tshaj plaws profile cross-section tsim tsis tsuas yog txo cov txheej txheem nyuaj los ntawm lub hauv paus, tab sis kuj txhim kho qhov zoo thiab siv cov nyhuv ntawm cov khoom, txo cov nqi thiab txo lub sij hawm xa khoom.

Tsab ntawv xov xwm no qhia txog ntau yam kev siv feem ntau hauv aluminium profile cross-section tsim los ntawm cov teeb meem tiag tiag hauv kev tsim khoom.

1. Aluminium profile seem tsim qauv

Aluminium profile extrusion yog ib txoj kev ua nyob rau hauv uas ib tug rhuab aluminium pas nrig yog loaded rau hauv lub extrusion chim, thiab lub siab yog siv los ntawm ib tug extruder rau extrude nws los ntawm ib tug tuag qhov ntawm ib tug muab cov duab thiab loj, ua rau cov yas deformation kom tau cov khoom yuav tsum tau. Txij li thaum lub pas nrig aluminium cuam tshuam los ntawm ntau yam xws li kub, extrusion ceev, deformation tus nqi, thiab pwm thaum lub sij hawm deformation txheej txheem, lub uniformity ntawm hlau ntws yog nyuaj rau tswj, uas coj tej yam nyuaj rau pwm tsim. Txhawm rau kom lub zog ntawm cov pwm thiab tsis txhob tawg, tawg, tawg, thiab lwm yam, yuav tsum tau zam hauv qhov profile seem tsim: loj cantilevers, me me qhib, qhov me me, ntxeem tau, asymmetrical, nyias-walled, tsis sib luag phab ntsa thickness, thiab lwm yam. Thaum tsim, peb yuav tsum xub txaus siab rau nws cov kev ua tau zoo nyob rau hauv cov nqe lus ntawm kev siv, kho kom zoo nkauj, thiab lwm yam. Qhov tshwm sim yog qhov kev daws teeb meem zoo tshaj plaws. Vim tias thaum cov neeg tsim qauv tsis muaj kev paub txog cov txheej txheem extrusion thiab tsis nkag siab txog cov txheej txheem cov khoom siv, thiab cov txheej txheem tsim khoom yuav tsum siab dhau thiab nruj, tus nqi tsim nyog yuav raug txo, tus nqi yuav nce, thiab qhov zoo tshaj plaws profile yuav tsis raug tsim. Yog li ntawd, lub hauv paus ntsiab lus ntawm aluminium profile seem tsim yog siv cov txheej txheem yooj yim tshaj plaws thaum ua kom txaus siab rau nws cov qauv tsim.

2. Qee lub tswv yim ntawm aluminium profile interface tsim

2.1 Kev them nyiaj yuam kev

Kaw yog ib qho tsis xws luag hauv kev tsim cov profile. Cov laj thawj tseem ceeb yog raws li nram no:

(1) Profiles nrog qhov sib sib zog nqus hla ntu qhib feem ntau yuav kaw thaum extruded.

(2) Stretching thiab straightening ntawm profiles yuav intensify lub kaw.

(3) Cov kua nplaum txhaj tshuaj nrog qee cov qauv kuj tseem yuav raug kaw vim qhov shrinkage ntawm colloid tom qab cov kua nplaum raug txhaj.

Yog hais tias lub kaw lus saum toj no tsis loj heev, nws tuaj yeem zam tau los ntawm kev tswj xyuas tus nqi ntws los ntawm kev tsim pwm; tab sis yog tias ntau yam yog superimposed thiab cov pwm tsim thiab cov txheej txheem cuam tshuam tsis tuaj yeem daws qhov kev kaw, kev them nyiaj ua ntej tuaj yeem muab rau hauv tus qauv tsim, uas yog, qhib ua ntej.

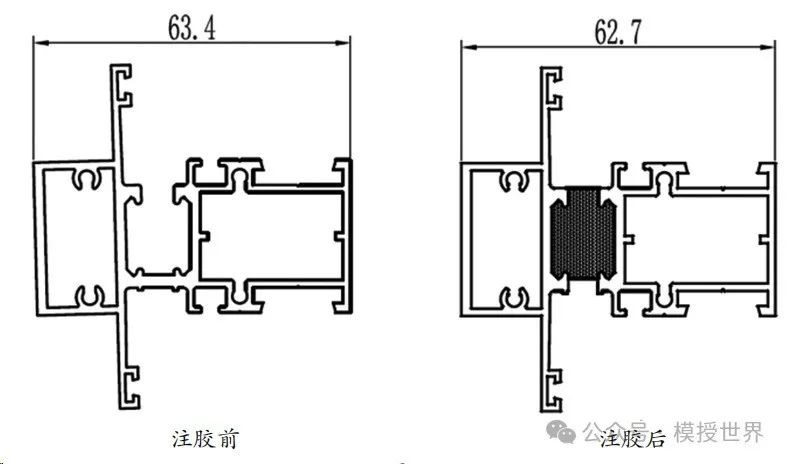

Tus nqi them ua ntej qhib yuav tsum raug xaiv raws li nws cov qauv tshwj xeeb thiab kev kaw dhau los. Lub sijhawm no, kev tsim cov pwm qhib daim duab (ua ntej qhib) thiab cov duab tiav yog txawv (Daim duab 1).

2.2 Faib qhov loj-loj rau hauv ntau qhov me me

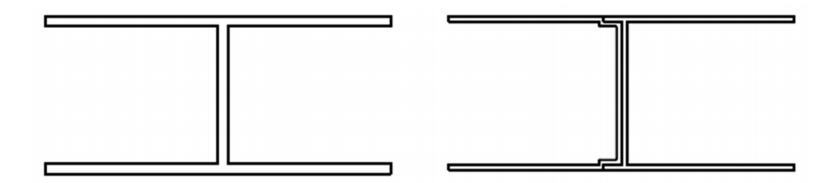

Nrog rau txoj kev loj hlob ntawm cov loj-scale txhuas profiles, tus ntoo khaub lig-sectional designs ntawm ntau profiles tau txais loj thiab loj, uas txhais tau hais tias ib tug series ntawm cov khoom xws li extruders loj, pwm loj, loj txhuas rods, thiab lwm yam yog xav tau los txhawb lawv, thiab cov nqi ntau lawm nce sharply. Rau qee qhov loj-loj seem uas tuaj yeem ua tiav los ntawm kev sib txuas, lawv yuav tsum tau muab faib ua ob peb ntu me me thaum tsim. Qhov no tuaj yeem tsis tsuas yog txo cov nqi xwb, tab sis kuj ua kom yooj yim dua los xyuas kom meej qhov flatness, curvature, thiab raug (Daim duab 2).

2.3 Teem lub ribs los txhim kho nws flatness

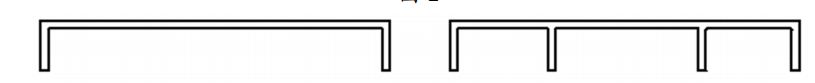

Cov kev cai flatness feem ntau ntsib thaum tsim cov seem profile. Me-span profiles yog ib qho yooj yim los xyuas kom meej flatness vim lawv cov qauv muaj zog. Ntev-ntev profiles yuav sag vim lawv tus kheej lub ntiajteb txawj nqus tom qab extrusion, thiab ib feem nrog qhov loj tshaj dabtsi yog khoov kev nyuaj siab nyob rau hauv nruab nrab yuav yog feem ntau concave. Tsis tas li ntawd, vim hais tias cov phab ntsa vaj huam sib luag yog ntev, nws yog ib qho yooj yim los tsim nthwv dej, uas yuav ua rau lub dav hlau tsis sib xws. Yog li ntawd, cov qauv loj-loj tiaj tiaj yuav tsum tau zam hauv kev tsim cov ntu ntu. Yog tias tsim nyog, kev txhawb nqa cov tav tuaj yeem ntsia tau rau hauv nruab nrab los txhim kho nws cov flatness. (Daim duab 3)

2.4 Secondary processing

Nyob rau hauv cov txheej txheem ntau lawm, qee ntu nyuaj ua kom tiav los ntawm kev ua extrusion. Txawm hais tias nws tuaj yeem ua tau, kev ua thiab cov nqi tsim khoom yuav siab dhau. Lub sijhawm no, lwm txoj kev ua haujlwm tuaj yeem xav txog.

Case 1: Qhov nrog txoj kab uas hla tsawg dua 4 hli ntawm qhov profile yuav ua rau cov pwm tsis muaj zog, yooj yim puas, thiab ua haujlwm nyuaj. Nws raug nquahu kom tshem tawm cov qhov me me thiab siv qhov drilling hloov.

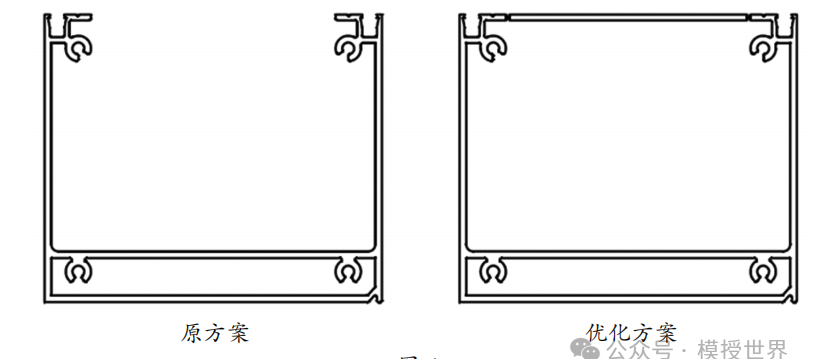

Case 2: Kev tsim cov qauv U-shaped grooves tsis yooj yim, tab sis yog tias qhov zawj qhov tob thiab qhov zawj dav tshaj 100mm, los yog qhov sib piv ntawm qhov dav dav rau qhov zawj qhov tob yog qhov tsis tsim nyog, cov teeb meem xws li pwm tsis txaus thiab qhov nyuaj ntawm kev ua kom qhov qhib yuav raug ntsib thaum lub sij hawm tsim khoom. Thaum tsim cov seem profile, qhov qhib tuaj yeem txiav txim siab kaw, yog li cov khoom qub pwm nrog lub zog tsis txaus tuaj yeem hloov mus rau hauv cov pwm ruaj khov, thiab yuav tsis muaj teeb meem ntawm kev qhib deformation thaum lub sij hawm extrusion, ua rau cov duab yooj yim los tswj. Tsis tas li ntawd, qee cov ntsiab lus tuaj yeem ua tiav ntawm kev sib txuas ntawm ob qhov kawg ntawm qhov qhib thaum tsim. Piv txwv li: teeb V-shaped marks, me grooves, thiab lwm yam, kom lawv tau yooj yim tshem tawm thaum lub sij hawm machining kawg (Daim duab 4).

2.5 Complex rau sab nraud tab sis yooj yim ntawm sab hauv

Aluminium profile extrusion pwm tuaj yeem muab faib ua cov pwm pwm thiab shunt pwm raws li seb qhov ntu ntu muaj kab noj hniav. Kev ua cov pwm pwm yog qhov yooj yim, thaum kev ua cov pwm shunt muaj cov txheej txheem nyuaj xws li kab noj hniav thiab cov taub hau. Yog li ntawd, tag nrho cov kev txiav txim siab yuav tsum tau muab rau tus tsim ntawm qhov profile seem, uas yog, sab nrauv contour ntawm seem tuaj yeem tsim kom yooj yim dua, thiab grooves, ntsia hlau qhov, thiab lwm yam. Nyob rau hauv txoj kev no, ob qho tib si pwm ua thiab kev saib xyuas yuav yooj yim dua, thiab tus nqi tawm los kuj yuav raug txhim kho.

2.6 Reserved margin

Tom qab extrusion, aluminium profiles muaj kev kho deg sib txawv raws li cov neeg siv khoom xav tau. Ntawm lawv, txoj kev anodizing thiab electrophoresis muaj kev cuam tshuam me ntsis ntawm qhov loj vim yog txheej txheej nyias nyias. Yog tias cov txheej txheem kev kho saum npoo ntawm cov hmoov txheej yog siv, cov hmoov yuav yooj yim sau rau hauv cov ces kaum thiab grooves, thiab cov tuab ntawm ib txheej tuaj yeem ncav cuag 100 μm. Yog tias qhov no yog txoj haujlwm sib dhos, xws li cov slider, nws yuav txhais tau hais tias muaj 4 txheej ntawm cov tshuaj tsuag txheej. Thickness mus txog 400 μm yuav ua rau kev sib dhos ua tsis tau thiab cuam tshuam rau kev siv.

Tsis tas li ntawd, raws li tus naj npawb ntawm extrusion nce thiab pwm hnav, qhov luaj li cas ntawm qhov profile slots yuav ua me thiab me, thaum qhov loj ntawm cov slider yuav loj dua thiab loj dua, ua rau kev sib dhos nyuaj dua. Raws li cov laj thawj saum toj no, cov npoo tsim nyog yuav tsum tau tshwj tseg raws li cov xwm txheej tshwj xeeb thaum lub sijhawm tsim los ua kom muaj kev sib dhos.

2.7 Tolerance cim

Rau kev tsim cov ntu ntu, cov duab sib dhos yog tsim ua ntej thiab tom qab ntawd cov khoom lag luam kos duab yog tsim. Kev kos duab sib dhos kom raug tsis txhais tau tias cov khoom lag luam kos duab zoo meej. Qee tus neeg tsim qauv tsis quav ntsej qhov tseem ceeb ntawm qhov loj me thiab kev ua siab ntev. Cov haujlwm cim npe feem ntau yog qhov ntev uas yuav tsum tau lav, xws li: txoj haujlwm sib dhos, qhib, zawj qhov tob, zawj dav, thiab lwm yam, thiab yooj yim rau kev ntsuas thiab tshuaj xyuas. Rau qhov dav dav dav dav, cov qib raug raug xaiv tau raws li lub teb chaws tus qauv. Qee qhov tseem ceeb los ua ke qhov ntev yuav tsum tau cim nrog qhov tshwj xeeb kam rau ua qhov tseem ceeb hauv daim duab. Yog tias kev kam rau siab loj dhau lawm, kev sib dhos yuav nyuaj dua, thiab yog tias qhov kev kam rau siab me me dhau lawm, tus nqi tsim khoom yuav nce ntxiv. Qhov tsim nyog kam rau ua ntau yam xav tau tus tsim qauv kev paub txhua hnub.

2.8 Cov kev kho kom ntxaws

Cov ntsiab lus txiav txim siab ua tiav lossis tsis ua tiav, thiab tib yam yog qhov tseeb rau qhov profile cross-section tsim. Cov kev hloov me me tuaj yeem tsis tsuas yog tiv thaiv pwm thiab tswj tus nqi ntws, tab sis kuj tseem txhim kho qhov zoo ntawm qhov chaw thiab ua kom cov qoob loo nce ntxiv. Ib qho ntawm cov txheej txheem siv feem ntau yog rounding fab. Extruded profiles tsis tuaj yeem muaj cov ces kaum ntse heev vim tias cov hlau nyias nyias siv hauv cov hlau txiav kuj muaj cov kab. Txawm li cas los xij, qhov khiav ceev ntawm cov ces kaum yog qeeb, kev sib txhuam loj, thiab qhov kev ntxhov siab yog concentrated, feem ntau muaj cov xwm txheej uas cov cim extrusion pom tseeb, qhov loj me yog qhov nyuaj rau kev tswj, thiab cov pwm tuaj yeem ua rau chipping. Yog li ntawd, lub vojvoog rounding yuav tsum tau nce ntau npaum li sai tau yam tsis muaj kev cuam tshuam rau nws siv.

Txawm hais tias nws yog tsim los ntawm lub tshuab extrusion me me, phab ntsa thickness ntawm qhov profile yuav tsum tsis txhob tsawg dua 0.8 hli, thiab phab ntsa thickness ntawm txhua qhov ntawm seem yuav tsum tsis txhob sib txawv los ntawm ntau tshaj 4 zaug. Thaum lub sij hawm tsim, kab kab pheeb ces kaum los yog arc hloov pauv tuaj yeem siv tau ntawm kev hloov pauv ntawm phab ntsa tuab kom ntseeg tau tias cov khoom tawm tsis tu ncua thiab kho pwm yooj yim. Tsis tas li ntawd, cov phab ntsa nyias nyias muaj qhov elasticity zoo dua, thiab cov phab ntsa tuab ntawm qee qhov gussets, battens, thiab lwm yam tuaj yeem yog li 1 hli. Muaj ntau daim ntawv thov rau kev kho cov ntsiab lus hauv kev tsim, xws li kho cov ces kaum, hloov cov lus qhia, shortening cantilevers, nce qhov khoob, txhim kho symmetry, kho kom haum, thiab lwm yam. Hauv luv luv, profile cross-section tsim yuav tsum tau txuas ntxiv cov ntsiab lus thiab innovation, thiab tag nrho txiav txim siab txog kev sib raug zoo nrog pwm tsim, kev tsim, thiab cov txheej txheem ntau lawm.

3. Cov lus xaus

Raws li tus tsim qauv, txhawm rau kom tau txais txiaj ntsig zoo tshaj plaws ntawm kev lag luam los ntawm kev tsim cov profile, txhua yam ntawm tag nrho lub neej voj voog ntawm cov khoom yuav tsum tau txiav txim siab thaum lub sij hawm tsim, nrog rau cov neeg siv kev xav tau, tsim, tsim, zoo, nqi, thiab lwm yam, sib zog ua kom tiav cov khoom tsim kev vam meej thawj zaug. Cov no yuav tsum tau taug qab txhua hnub ntawm cov khoom tsim tawm thiab kev sau thiab khaws cov ntaub ntawv thawj zaug txhawm rau kwv yees cov txiaj ntsig tsim thiab kho lawv ua ntej.

Post lub sij hawm: Sep-10-2024