Cov txheej txheem ntawm aluminium alloy tsheb log yog feem ntau muab faib ua pawg hauv qab no:

1. Casting txheej txheem:

• Lub ntiajteb txawj nqus casting: Muab cov kua aluminium alloy rau hauv pwm, sau cov pwm hauv qab lub ntiajteb txawj nqus thiab txias kom zoo. Cov txheej txheem no muaj cov cuab yeej siv qis thiab kev ua haujlwm yooj yim, uas yog tsim rau cov khoom me me. Txawm li cas los xij, qhov kev ua tau zoo ntawm casting yog tsawg, cov khoom lag luam zoo sib xws yog qhov tsis zoo, thiab qhov tsis xws luag xws li qhov pores thiab shrinkage yog qhov tshwm sim.

• Tsawg-pressure casting: Nyob rau hauv lub kaw crucible, cov kua aluminium alloy yog nias rau hauv pwm ntawm qhov tsis tshua muaj siab los ntawm cov roj inert kom solidify nws nyob rau hauv siab. Cov castings tsim los ntawm cov txheej txheem no muaj cov qauv ntom ntom, zoo sab hauv, kev ua haujlwm siab, thiab tsim nyog rau ntau lawm, tab sis cov cuab yeej siv tau loj, cov pwm xav tau siab, thiab cov pwm pwm kuj siab.

• Spin casting: Nws yog cov txheej txheem txhim kho raws li qhov qis-siab casting. Ua ntej, qhov khoob ntawm lub log yog tsim los ntawm qhov tsis tshua muaj siab casting, thiab tom qab ntawd qhov khoob yog tsau ntawm lub tshuab spinning. Cov qauv ntawm lub npoo yog maj mam deformed thiab txuas ntxiv los ntawm cov pwm rotating thiab siab. Cov txheej txheem no tsis tsuas yog khaws cov txiaj ntsig zoo ntawm qhov tsis tshua muaj siab casting, tab sis kuj txhim kho lub zog thiab precision ntawm lub log, thaum tseem txo qhov hnyav ntawm lub log.

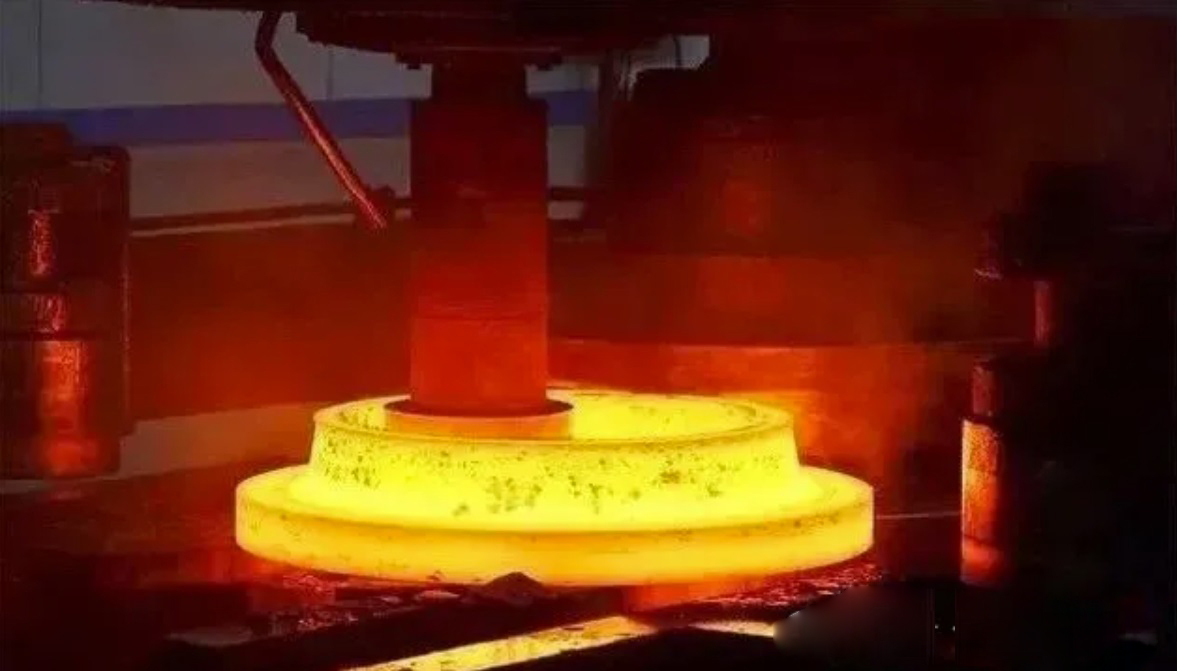

2. txheej txheem forging

Tom qab aluminium alloy yog rhuab mus rau ib qho kub, nws yog forged rau hauv pwm los ntawm forging xovxwm. Cov txheej txheem forging tuaj yeem muab faib ua ob hom hauv qab no:

• Pa forging: Tag nrho daim ntawm txhuas ingot yog ncaj qha forged rau hauv cov duab ntawm lub log nyob rau hauv siab. Lub log tsim los ntawm cov txheej txheem no muaj kev siv cov khoom siv siab, tsis tshua muaj pov tseg, zoo heev txhua yam khoom ntawm forgings, thiab zoo zog thiab toughness. Txawm li cas los xij, kev nqis peev ntawm cov cuab yeej yog loj, cov txheej txheem yog complex, thiab cov txheej txheem ntawm tus neeg teb xov tooj yuav tsum tau siab.

• Semi-khoom forging: Ua ntej, aluminium alloy yog rhuab mus rau ib lub xeev semi-khoom, thaum lub sij hawm lub txhuas alloy muaj ib tug tej yam fluidity thiab forgeability, thiab ces forged. Cov txheej txheem no tuaj yeem txo qis kev siv hluav taws xob hauv cov txheej txheem forging, txhim kho kev tsim khoom, thiab tseem txhim kho lub log zoo.

3. Vuam txheej txheem

Daim ntawv yog dov mus rau hauv lub tog raj kheej thiab welded, thiab nws tsuas yog ua tiav los yog nias rau hauv lub log nrog pwm, thiab tom qab ntawd lub pre-cast wheel disc yog welded los tsim lub log. Cov txheej txheem vuam tuaj yeem yog laser vuam, electron beam vuam, thiab lwm yam txheej txheem no yuav tsum muaj cov kab ntau lawm nrog kev ua haujlwm siab thiab tsim nyog rau cov khoom loj, tab sis cov tsos tsis zoo thiab cov teeb meem vuam tsis zoo yuav tshwm sim ntawm cov ntsiab lus vuam.

Post lub sij hawm: Nov-27-2024