1 Txheej txheem cej luam

Cov txheej txheem ntau lawm ntawm thermal rwb thaiv tsev threading profile yog qhov nyuaj, thiab cov txheej txheem threading thiab laminating kuj lig. Cov khoom semi-tiav lawm ntws mus rau hauv cov txheej txheem no yog ua tiav los ntawm kev ua haujlwm nyuaj ntawm ntau tus neeg ua haujlwm ua ntej. Thaum cov khoom pov tseg tshwm nyob rau hauv cov txheej txheem sib xyaw striping, lawv yuav Yog tias nws ua rau muaj kev lag luam loj heev, nws yuav ua rau poob ntawm ntau qhov kev ua haujlwm dhau los, ua rau cov khib nyiab loj.

Thaum lub sij hawm tsim cov thermal rwb thaiv tsev threading profiles, profiles feem ntau scrapped vim muaj ntau yam. Qhov laj thawj tseem ceeb ntawm cov khoom seem hauv cov txheej txheem no yog qhov tawg ntawm cov cua sov-insulating strip notches. Muaj ntau qhov laj thawj rau kev tawg ntawm lub tshav kub-insulating sawb, ntawm no peb tsuas yog tsom mus rau cov txheej txheem ntawm kev nrhiav cov laj thawj ntawm qhov tsis xws luag xws li shrinktail thiab stratification los ntawm cov txheej txheem extrusion, uas ua rau tawg ntawm cov notches ntawm aluminium alloy tshav kub rwb thaiv tsev profiles thaum lub sij hawm threading thiab laminating, thiab daws qhov teeb meem no los ntawm kev txhim kho pwm thiab lwm yam.

2 Teeb meem tshwm sim

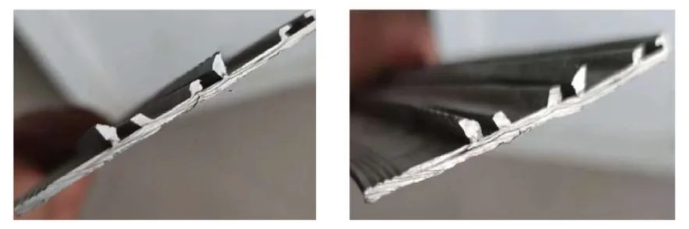

Thaum lub sij hawm tsim cov txheej txheem ntawm tshav kub rwb thaiv tsev threading profiles, batch cracking ntawm tshav kub-insulating notches dheev tshwm sim. Tom qab kuaj xyuas, qhov tshwm sim tawg muaj qee yam qauv. Nws tag nrho cov kab nrib pleb ntawm qhov kawg ntawm ib qho qauv, thiab cov kab nrib pleb ntev yog tib yam. Nws yog nyob rau hauv ib tug tej yam ntau yam (20-40cm los ntawm qhov kawg), thiab nws yuav rov zoo li qub tom qab lub sij hawm ntawm tawg. Cov duab tom qab tawg yog qhia hauv daim duab 1 thiab daim duab 2.

3 Nrhiav teeb meem

1) Ua ntej, faib cov teeb meem profiles thiab khaws cia ua ke, tshawb xyuas qhov tshwm sim tawg ib qho los ntawm ib qho, thiab tshawb pom qhov sib txawv thiab qhov sib txawv ntawm kev tawg. Tom qab rov qab taug qab, qhov tshwm sim ntawm kev tawg muaj qee yam qauv. Nws tag nrho cov tawg ntawm qhov kawg ntawm ib qho qauv. Cov duab ntawm cov qauv tawg yog ib qho khoom siv uas tsis muaj kab noj hniav, thiab qhov tawg ntev yog nyob rau hauv ib qho kev sib txawv. Tsis pub dhau (20-40cm los ntawm qhov kawg), nws yuav rov zoo li qub tom qab tawg rau ib pliag.

2) Los ntawm daim ntawv txheeb xyuas cov khoom ntawm cov khoom siv no, peb tuaj yeem tshawb pom tus lej pwm siv hauv kev tsim cov hom no, thaum lub sijhawm tsim khoom, qhov loj me ntawm qhov ntsuas ntawm tus qauv no raug kuaj, thiab qhov loj me me ntawm cov rwb thaiv tsev kub, cov khoom siv ntawm cov profile thiab cov hardness yog tag nrho nyob rau hauv qhov tsim nyog ntau yam.

3) Thaum lub sij hawm tsim cov txheej txheem sib xyaw, cov txheej txheem sib xyaw ua ke thiab kev ua haujlwm ntau lawm tau taug qab. Tsis muaj qhov txawv txav, tab sis tseem muaj cov kab nrib pleb thaum lub batch ntawm profiles raug tsim.

4) Tom qab kuaj xyuas qhov tawg ntawm qhov tawg, qee cov qauv tsis txuas ntxiv tau pom. Xav txog tias qhov ua rau ntawm qhov tshwm sim no yuav tsum yog los ntawm extrusion tsis xws luag los ntawm cov txheej txheem extrusion.

5) Los ntawm cov xwm txheej saum toj no, nws tuaj yeem pom tias qhov ua rau tawg tsis yog qhov nyuaj ntawm qhov profile thiab cov txheej txheem sib xyaw, tab sis yog thawj zaug txiav txim siab los ntawm extrusion defects. Txhawm rau txhawm rau txheeb xyuas qhov laj thawj ntawm qhov teeb meem, cov kev sim hauv qab no tau ua.

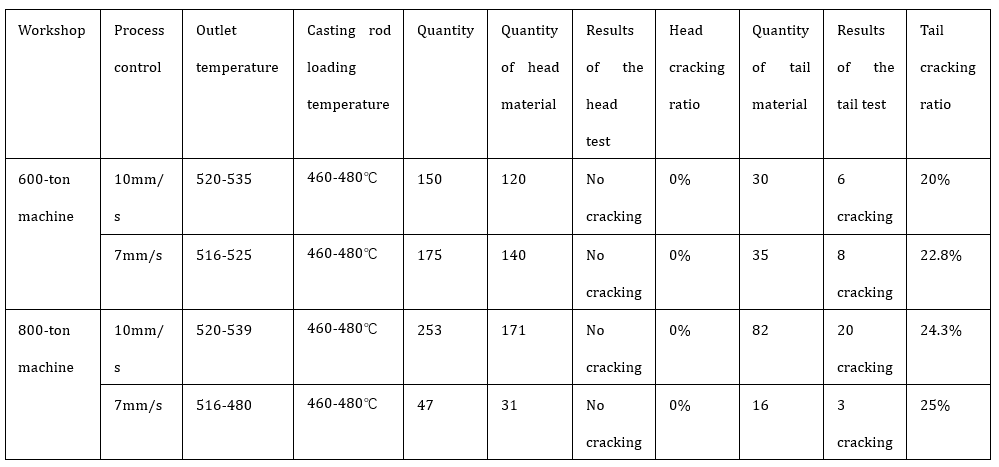

6) Siv tib txheej pwm los ua cov kev ntsuam xyuas ntawm cov tshuab tonnage sib txawv nrog qhov sib txawv extrusion ceev. Siv lub tshuab 600-tuj thiab lub tshuab 800-tuj los ua qhov kev xeem. Kos lub taub hau thiab cov khoom siv sib cais thiab ntim rau hauv pob tawb. Lub hardness tom qab laus ntawm 10-12HW. Txoj kev alkaline dej corrosion yog siv los kuaj qhov profile ntawm lub taub hau thiab tus Tsov tus tw ntawm cov khoom. Nws tau pom tias cov khoom siv tus Tsov tus tw tau shrink Tail thiab stratification phenomena. Qhov ua rau ntawm qhov tawg tau txiav txim siab yog tshwm sim los ntawm shrinktail thiab stratification. Cov duab tom qab alkali etching yog qhia nyob rau hauv daim duab 2 thiab 3. Composite tests tau ua nyob rau hauv no batch ntawm profiles los xyuas qhov tshwm sim tawg. Cov ntaub ntawv xeem tau qhia hauv Table 1.

Cov duab 2 thiab 3

7) Los ntawm cov ntaub ntawv hauv cov lus saum toj no, nws tuaj yeem pom tias tsis muaj qhov tawg ntawm lub taub hau ntawm cov khoom siv, thiab qhov kev faib ua ke ntawm qhov sib tsoo ntawm tus Tsov tus tw yog qhov loj tshaj plaws. Qhov ua rau tawg muaj me ntsis ua rau qhov loj ntawm lub tshuab thiab qhov ceev ntawm lub tshuab. Qhov sib piv ntawm cov khoom siv tus Tsov tus tw yog qhov loj tshaj plaws, uas yog ncaj qha ntsig txog qhov ntev sawing ntawm tus Tsov tus tw. Tom qab qhov tawg yog soaked nyob rau hauv dej alkaline thiab kuaj, shrink tail thiab stratification yuav tshwm. Thaum lub shrink Tail thiab stratification qhov chaw raug txiav tawm, yuav tsis muaj cracking.

4 Txoj kev daws teeb meem thiab kev tiv thaiv kev tiv thaiv

1) Txhawm rau txo qis kev tawg vim yog vim li no, txhim kho cov txiaj ntsig, thiab txo cov khoom pov tseg, cov kev ntsuas hauv qab no raug coj los tswj kev tsim khoom. Qhov kev daws teeb meem no yog tsim rau lwm cov qauv zoo ib yam li cov qauv no qhov twg cov extrusion tuag yog lub tiaj tiaj. Lub shrink tail thiab stratification phenomena tsim thaum lub sij hawm extrusion ntau lawm yuav ua rau muaj teeb meem zoo xws li tawg ntawm qhov kawg notches thaum lub sij hawm compounding.

2) Thaum txais cov pwm, nruj me ntsis tswj qhov loj me me; siv ib daim ntawm cov khoom los ua ib qho pwm, ntxiv ob chav vuam chamber rau pwm, los yog qhib ib tug cuav phua pwm kom txo tau qhov zoo cuam tshuam ntawm shrink tail thiab stratification ntawm cov khoom tiav.

3) Thaum lub sij hawm extrusion ntau lawm, qhov saum npoo ntawm txhuas pas nrig yuav tsum huv si thiab tsis muaj plua plav, roj thiab lwm yam paug. Cov txheej txheem extrusion yuav tsum tau txais yuav maj mam attenuated extrusion hom. Qhov no tuaj yeem ua rau qeeb qeeb ntawm qhov tso tawm ntawm qhov kawg ntawm extrusion thiab txo qis tus Tsov tus tw thiab stratification.

4) Tsis tshua muaj kub thiab kub ceev extrusion yog siv thaum lub sij hawm extrusion ntau lawm, thiab qhov kub ntawm aluminium pas nrig ntawm lub tshuab yog tswj ntawm 460-480 ℃. Cov pwm kub yog tswj ntawm 470 ℃ ± 10 ℃, extrusion chim kub tswj ntawm li 420 ℃, thiab extrusion qhov hluav taws xob kub tswj ntawm 490-525 ℃. Tom qab extrusion, lub kiv cua yog qhib kom txias. Qhov seem ntev yuav tsum tau nce ntau dua 5 hli dua li niaj zaus.

5) Thaum tsim cov hom profile no, nws yog qhov zoo tshaj plaws los siv lub tshuab loj dua los ua kom lub zog extrusion, txhim kho qib ntawm cov hlau fusion, thiab xyuas kom meej cov khoom ntom ntom.

6) Thaum lub sij hawm extrusion ntau lawm, lub thoob dej alkali yuav tsum tau npaj ua ntej. Tus neeg teb xov tooj yuav pom tawm tus Tsov tus tw ntawm cov khoom los xyuas qhov ntev ntawm lub shrinktail thiab stratification. Cov kab txaij dub rau ntawm qhov chaw alkali-etched qhia tias shrinktail thiab stratification tau tshwm sim. Tom qab ntxiv sawing, Kom txog rau thaum lub hla-section yog ci thiab tsis muaj kab txaij dub, kos 3-5 txhuas rods kom pom qhov ntev hloov tom qab shrink Tail thiab stratification. Txhawm rau kom tsis txhob thim tus Tsov tus tw thiab stratification los ntawm kev coj mus rau cov khoom profile, 20cm yog ntxiv raws li qhov ntev tshaj plaws, txiav txim siab qhov ntev ntawm tus Tsov tus tw ntawm cov pwm teeb, pom tawm qhov teeb meem thiab pib sawing rau hauv cov khoom tiav. Thaum lub sij hawm ua hauj lwm, lub taub hau thiab tus Tsov tus tw ntawm cov khoom yuav staggered thiab sawed flexibly, tab sis tsis xws luag yuav tsum tsis txhob muab coj mus rau lub profile khoom. Saib xyuas thiab tshuaj xyuas los ntawm kev tshuaj xyuas tshuab zoo. Yog tias qhov ntev ntawm tus Tsov tus tw thiab stratification cuam tshuam rau cov txiaj ntsig, tshem tawm cov pwm hauv lub sijhawm thiab txiav cov pwm kom txog thaum nws zoo li qub ua ntej cov khoom lag luam tuaj yeem pib.

5 Cov ntsiab lus

1) Ob peb lub tshav kub-insulating strip profiles tsim los ntawm cov txheej txheem saum toj no tau sim thiab tsis muaj qhov zoo sib xws ntawm qhov tawg. Cov yam ntxwv ntawm shear qhov tseem ceeb ntawm cov profiles tag nrho mus txog lub teb chaws tus qauv GB / T5237.6-2017 yuav tsum "Aluminium Alloy Building Profiles No. 6 Tshooj: rau Insulating Profiles".

2) Txhawm rau tiv thaiv qhov tshwm sim ntawm qhov teeb meem no, kev tshuaj xyuas txhua hnub tau tsim los daws cov teeb meem hauv lub sijhawm thiab kho kom tsis txhob muaj cov phom sij txaus ntshai los ntawm kev ntws mus rau hauv cov txheej txheem sib xyaw thiab txo cov khoom pov tseg hauv cov txheej txheem tsim khoom.

3) Ntxiv nrog rau kev zam kev tawg los ntawm extrusion defects, shrink tail thiab stratification, peb yuav tsum nco ntsoov xyuam xim rau qhov tshwm sim tawg tshwm sim los ntawm cov yam ntxwv xws li geometry ntawm qhov ntsuas, qhov hardness ntawm cov khoom thiab cov khoom siv thiab cov txheej txheem ntawm cov txheej txheem sib xyaw.

Kho los ntawm May Jiang los ntawm MAT Aluminium

Post lub sij hawm: Jun-22-2024