Nrog rau kev paub txog kev tiv thaiv ib puag ncig, kev txhim kho thiab kev tawm tswv yim ntawm lub zog tshiab thoob ntiaj teb tau ua rau kev txhawb nqa thiab kev siv lub zog tsheb yuav tshwm sim. Nyob rau tib lub sijhawm, qhov yuav tsum tau ua rau kev txhim kho lub teeb yuag ntawm cov khoom siv tsheb, kev nyab xeeb ntawm kev siv aluminium alloy, thiab lawv qhov zoo, qhov loj me thiab cov khoom siv tshuab tau dhau los ua ntau dua. Noj EV nrog lub tsheb hnyav ntawm 1.6t ua piv txwv, cov khoom siv aluminium alloy yog li 450kg, suav txog li 30%. Qhov chaw tsis xws luag uas tshwm sim nyob rau hauv cov txheej txheem extrusion ntau lawm, tshwj xeeb tshaj yog cov coarse grain teeb meem ntawm sab hauv thiab sab nrauv, cuam tshuam rau kev loj hlob ntawm txhuas profiles thiab ua lub bottleneck ntawm lawv daim ntawv thov kev loj hlob.

Rau extruded profiles, tsim thiab tsim ntawm extrusion tuag yog qhov tseem ceeb tshaj plaws, yog li kev tshawb fawb thiab kev loj hlob ntawm tuag rau EV txhuas profiles yog qhov tseem ceeb. Tshaj tawm kev tshawb fawb thiab tsim nyog cov kev daws teeb meem tuaj yeem txhim kho qhov tsim nyog tus nqi thiab extrusion productivity ntawm EV txhuas profiles kom tau raws li kev lag luam xav tau.

1 Cov Qauv Khoom

(1) Cov ntaub ntawv, kev kho deg thiab tiv thaiv corrosion ntawm cov khoom thiab cov khoom yuav tsum ua raws li cov kev cai ntawm ETS-01-007 "Technical Requirements for Aluminium Alloy Profile Parts" thiab ETS-01-006 "Technical Requirements for Anodic Oxidation Surface Treatment".

(2) Kev kho deg: Anodic oxidation, nto yuav tsum tsis muaj coarse nplej.

(3) Qhov saum npoo ntawm qhov chaw tsis raug tso cai kom muaj qhov tsis xws luag xws li tawg thiab wrinkles. Cov khoom tsis raug tso cai kom muaj kab mob tom qab oxidation.

(4) Cov khoom txwv tsis pub ua tau raws li qhov yuav tsum tau ua ntawm Q / JL J160001-2017 "Cov Lus Cog Tseg rau Cov Khoom Siv Hluav Taws Xob thiab Cov Khoom Siv Hluav Taws Xob".

(5) Mechanical kev ua tau zoo: tensile zog ≥ 210 MPa, yield zog ≥ 180 MPa, elongation tom qab tawg A50 ≥ 8%.

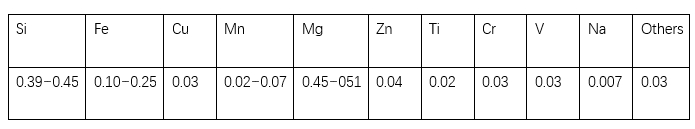

(6) Cov kev cai rau txhuas alloy muaj pes tsawg leeg rau lub zog tshiab tsheb yog qhia nyob rau hauv Table 1.

2 Kev ua kom zoo dua qub thiab kev sib piv ntawm cov txheej txheem extrusion tuag loj-txheej fais fab tuag tshwm sim

(1) Cov kev daws teeb meem 1: uas yog, txhawm rau txhim kho pem hauv ntej extrusion tuag tsim, raws li qhia hauv daim duab 2. Raws li cov qauv tsim qauv, raws li pom los ntawm xub xub hauv daim duab, qhov nruab nrab tav txoj hauj lwm thiab sublingual drainage txoj hauj lwm yog ua tiav, lub sab sauv thiab sab qis yog 20 ° ntawm ib sab, thiab cov kua dej siab H15 mmol b. Lub sublingual khoob riam yog pauv ntawm lub kaum sab xis, thiab cov molten aluminium tseem nyob ntawm lub ces kaum, uas yog ib qho yooj yim los tsim cov chaw tuag nrog txhuas slag. Tom qab ntau lawm, nws tau txheeb xyuas los ntawm oxidation tias qhov saum npoo yog qhov yooj yim heev rau coarse grain teeb meem.

Cov hauv qab no ua ntej optimizations tau ua rau cov txheej txheem pwm tsim:

ib. Raws li cov pwm no, peb tau sim ua kom cov khoom txhuas ntxiv rau cov tav los ntawm kev pub mis.

b. Nyob rau hauv lub hauv paus ntawm tus thawj qhov tob, lub sublingual khoob riam qhov tob yog tob, uas yog, 5 hli yog ntxiv rau thawj 15 hli;

c. Qhov dav ntawm sublingual khoob hniav yog widened los ntawm 2 hli raws li tus thawj 14 hli. Daim duab tiag tiag tom qab kev ua kom zoo yog pom hauv daim duab 3.

Cov txiaj ntsig pov thawj pom tau tias tom qab peb qhov kev txhim kho ua ntej saum toj no, coarse grain defects tseem muaj nyob hauv cov profiles tom qab kev kho oxidation thiab tsis tau daws qhov teeb meem. Qhov no qhia tau hais tias qhov kev txhim kho ua ntej tseem tsis tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm aluminium alloy cov ntaub ntawv rau EVs.

(2) Tshiab Scheme 2 tau npaj raws li qhov ua ntej ua kom zoo dua qub. Cov pwm tsim ntawm New Scheme 2 yog nyob rau hauv daim duab 4. Raws li "hlau fluidity hauv paus ntsiab lus" thiab "txoj cai ntawm qhov tsawg kawg nkaus tsis kam", qhov txhim kho automotive qhov pwm siv lub "qhib rov qab qhov" tsim qauv. Lub tav txoj hauj lwm plays lub luag hauj lwm nyob rau hauv ncaj qha cuam tshuam thiab txo kev sib txhuam tsis kam; qhov chaw pub khoom yog tsim los ua "lub lauj kaub npog-zoo li" thiab tus choj txoj haujlwm tau ua tiav rau hauv hom amplitude, lub hom phiaj yog kom txo qis kev sib txhuam, txhim kho fusion, thiab txo extrusion siab; tus choj yog sunken kom ntau li ntau tau los tiv thaiv qhov teeb meem ntawm coarse nplej nyob rau hauv qab ntawm tus choj, thiab qhov dav ntawm lub khoob riam nyob rau hauv tus nplaig ntawm tus choj hauv qab yog ≤3mm; Cov kauj ruam sib txawv ntawm txoj siv sia ua haujlwm thiab kev siv lub cev qis qis yog ≤1.0mm; rab riam npliag nyob rau hauv lub Upper tuag tus nplaig yog du thiab tusyees hloov, tsis tau tawm hauv ib tug txaus barrier, thiab lub forming qhov yog punched ncaj qha li sai tau; txoj siv sia ua haujlwm nruab nrab ntawm ob lub taub hau ntawm nruab nrab sab hauv tav yog luv li sai tau, feem ntau siv tus nqi ntawm 1.5 mus rau 2 npaug ntawm phab ntsa tuab; lub qhov dej ntws tawm muaj kev hloov pauv kom tau raws li qhov yuav tsum tau muaj cov hlau txhuas cov dej txaus ntws mus rau hauv cov kab noj hniav, nthuav tawm tag nrho lub xeev fused, thiab tsis muaj qhov chaw tuag ntawm txhua qhov chaw (qhov khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob. Kev sib piv ntawm extrusion tuag qauv ua ntej thiab tom qab kev txhim kho yog pom nyob rau hauv daim duab 5.

(3) Ua tib zoo saib xyuas kev txhim kho cov txheej txheem ua tiav. Tus choj txoj hauj lwm yog polished thiab txuas smoothly, lub Upper thiab qis tuag ua hauj lwm txoj siv sia yog tiaj tus, lub deformation kuj yog txo, thiab cov hlau txaus yog txhim kho kom txo tau lub uneven deformation. Nws tuaj yeem cuam tshuam cov teeb meem xws li cov nplej ntxhib thiab vuam, yog li ua kom ntseeg tau tias txoj haujlwm rib tawm thiab qhov ceev ntawm tus choj hauv paus yog synchronized nrog rau lwm qhov chaw, thiab tsim nyog thiab kev tshawb fawb los tiv thaiv cov teeb meem saum npoo xws li coarse grain welding ntawm qhov chaw ntawm aluminium profile. Qhov kev sib piv ua ntej thiab tom qab kev txhim kho cov kua dej yog qhia hauv daim duab 6.

3 Extrusion txheej txheem

Rau 6063-T6 aluminium alloy rau EVs, qhov sib piv extrusion ntawm kev sib cais tuag yog suav tias yog 20-80, thiab qhov sib piv ntawm cov khoom siv txhuas no hauv 1800t tshuab yog 23, uas ua tau raws li qhov yuav tsum tau ua ntawm lub tshuab. Cov txheej txheem extrusion yog qhia hauv Table 2.

Table 2 Extrusion ntau lawm txheej txheem ntawm txhuas profiles rau mounting kab teeb ntawm tshiab EV roj teeb pob

Ua tib zoo mloog cov ntsiab lus hauv qab no thaum extruding:

(1) Nws yog txwv tsis pub kom sov cov pwm nyob rau hauv tib lub cub tawg, txwv tsis pub cov pwm kub yuav tsis sib xws thiab crystallization yuav tshwm sim yooj yim.

(2) Yog tias muaj qhov txawv txav tshwm sim thaum lub sij hawm extrusion txheej txheem, lub sij hawm kaw yuav tsum tsis pub tshaj 3 feeb, txwv tsis pub cov pwm yuav tsum tau muab tshem tawm.

(3) Nws yog txwv tsis pub rov qab mus rau lub qhov cub kom sov thiab tom qab ntawd extrude ncaj qha tom qab demolding.

4. Pwm kho kev ntsuas thiab lawv cov kev ua tau zoo

Tom qab kaum ob ntawm kev kho pwm thiab kev sim pwm txhim kho, cov txheej txheem kho pwm tsim nyog hauv qab no tau npaj.

(1) Ua qhov kev kho thawj zaug thiab kev kho kom haum rau cov pwm qub:

① Sim tso tus choj kom ntau li ntau tau, thiab qhov dav ntawm tus choj hauv qab yuav tsum yog ≤3mm;

② Cov kauj ruam sib txawv ntawm txoj siv sia ua haujlwm ntawm lub taub hau thiab txoj siv sia ua haujlwm ntawm cov pwm qis yuav tsum yog ≤1.0mm;

③ Tsis txhob tawm ntawm qhov ntws tawm;

④ Txoj siv sia ua haujlwm ntawm ob tug txiv neej lub taub hau ntawm lub puab tsaig sab hauv yuav tsum yog luv li sai tau, thiab kev hloov ntawm cov kav dej yuav tsum du, loj thiab du li sai tau;

⑤ Txoj siv sia ua haujlwm ntawm cov pwm qis yuav tsum luv li sai tau;

⑥ Tsis muaj qhov chaw tuag yuav tsum tau tso rau ntawm txhua qhov chaw (lub nraub qaum khoob yuav tsum tsis pub tshaj 2 hli);

⑦ Kho cov pwm sab saud nrog cov nplej ntxhib hauv cov kab noj hniav hauv sab hauv, txo txoj siv sia ua haujlwm ntawm cov pwm qis thiab ua kom cov dej ntws ntws, lossis tsis muaj qhov ntws thaiv thiab ua kom txoj siv sia ua haujlwm ntawm cov pwm qis.

(2) Raws li kev hloov pwm ntxiv thiab kev txhim kho ntawm cov pwm saum toj no, cov kev hloov pwm hauv qab no tau ua:

① Tshem tawm qhov chaw tuag ntawm ob tug txiv neej lub taub hau;

② Tshem tawm qhov ntws thaiv;

③ Txo qhov siab qhov sib txawv ntawm lub taub hau thiab qhov chaw ua haujlwm qis;

④ Txo qhov qis qis ua haujlwm ua haujlwm.

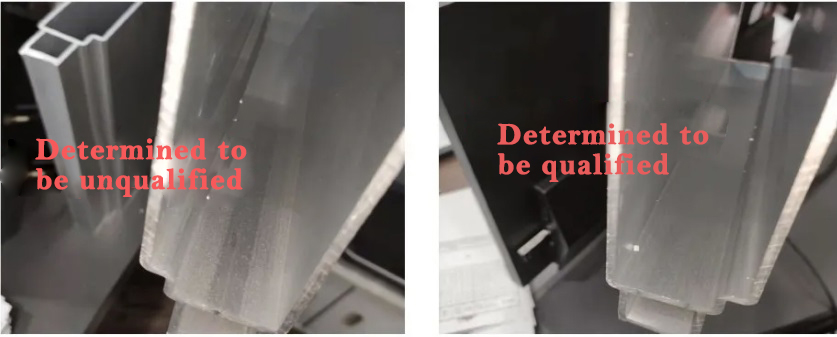

(3) Tom qab cov pwm tau kho thiab txhim kho, qhov zoo ntawm cov khoom tiav tau ncav cuag lub xeev zoo, nrog lub ntsej muag ci thiab tsis muaj cov nplej ntxhib, uas daws tau cov teeb meem ntawm cov nplej ntxhib, vuam thiab lwm yam tsis xws luag uas muaj nyob rau saum npoo ntawm aluminium profiles rau EVs.

(4) Lub ntim extrusion tau nce los ntawm thawj 5 t / d mus rau 15 t / d, txhim kho kev ua haujlwm zoo heev.

5 Kev xaus

Los ntawm kev rov ua kom zoo dua qub thiab txhim kho cov pwm qub, qhov teeb meem loj ntsig txog cov pob zeb ntxhib ntawm qhov chaw thiab vuam ntawm aluminium profiles rau EVs tau daws tag nrho.

(1) Qhov sib txuas tsis muaj zog ntawm cov pwm qub, cov kab nruab nrab ntawm txoj kab nruab nrab, tau ua kom zoo dua qub. Los ntawm kev tshem tawm qhov chaw tuag ntawm ob lub taub hau, flattening qhov ntws thaiv, txo qhov siab qhov sib txawv ntawm lub taub hau thiab qhov chaw ua haujlwm qis, thiab txo qis qhov chaw ua haujlwm qis, qhov tsis xws luag ntawm 6063 aluminium alloy siv nyob rau hauv hom tsheb no, xws li coarse nplej thiab vuam, tau ua tiav.

(2) Lub ntim extrusion tau nce los ntawm 5 t / d mus rau 15 t / d, txhim kho ntau lawm efficiency.

(3) Qhov kev vam meej ntawm extrusion tuag tsim thiab tsim khoom yog tus sawv cev thiab siv tau hauv kev tsim cov profiles zoo sib xws thiab tsim nyog ntawm kev nce qib.

Post lub sij hawm: Nov-16-2024